8 Technical data - functions

8.1

EC - standard encoder evaluation

8.1.1 Supported encoder systems

Supported Encoder Systems

Encoder systems with a supply voltage of 5 and 12 volt:

● MSM motor encoder

● MSK motor encoder

● Sin-cos encoder 1V

pp

; HIPERFACE®

● Sin-cos encoder 1V

pp

; EnDat 2.1; (EnDat 2.2 in preparation)

● Sin-cos encoder 1V

pp

; with reference track

● 5V-TTL square-wave encoder; with reference track

● SSI

● Combined encoder for SSI (combination of SSI and sin-cos encoder

1V

pp

)

● Resolver (resolvers are not supported if an optional "Safe Motion" safety

technology is available at the same time.)

● Hall sensor box SHL02.1

● Digital Hall sensor in conjunction with Hall sensor adapter box SHL03.1

8.1.2 Encoder type

IndraDyn S MSM motors (5V supply voltage)

Properties

Encoder systems of the MSM motors are digital encoder systems that can be

evaluated in absolute form.

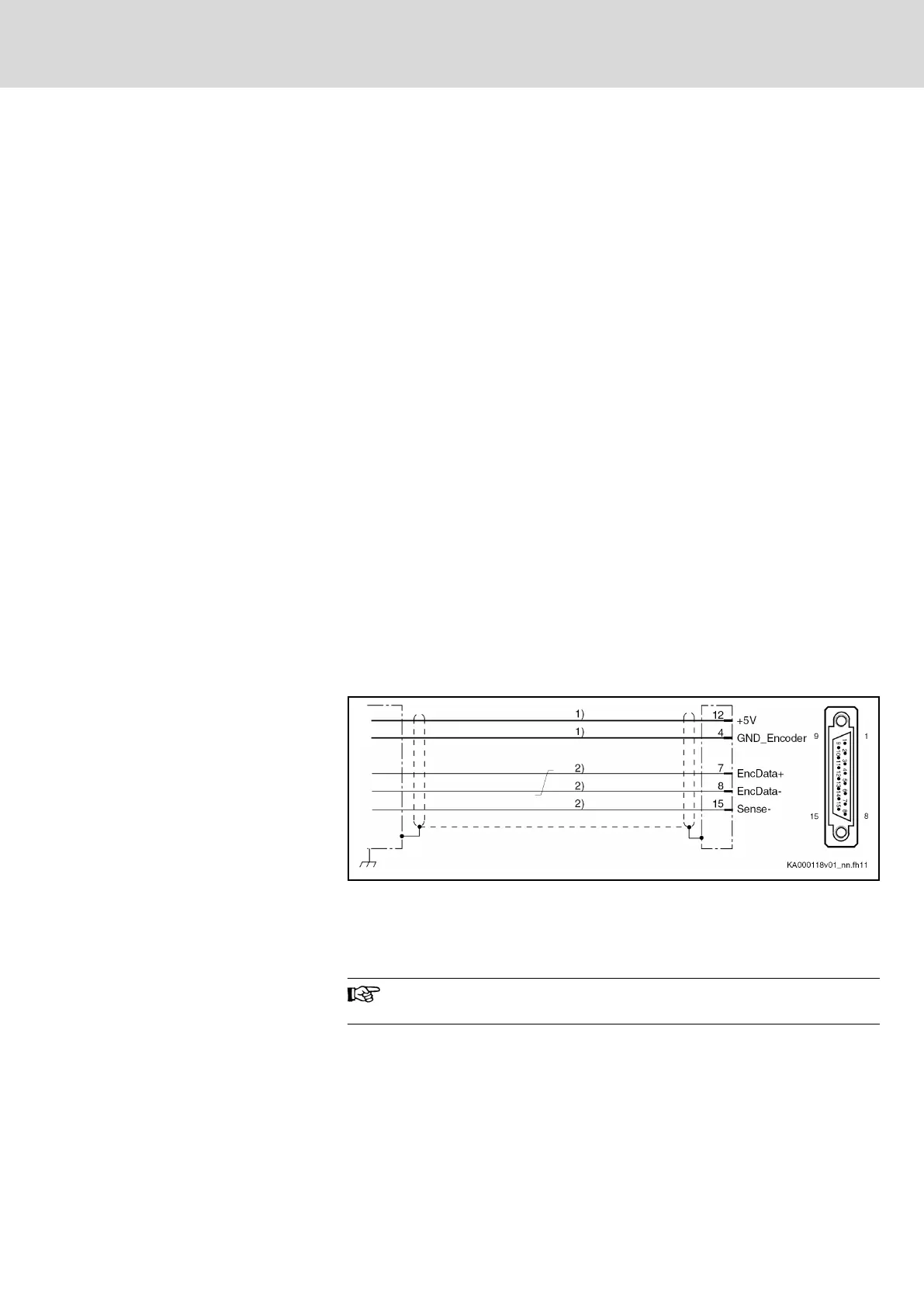

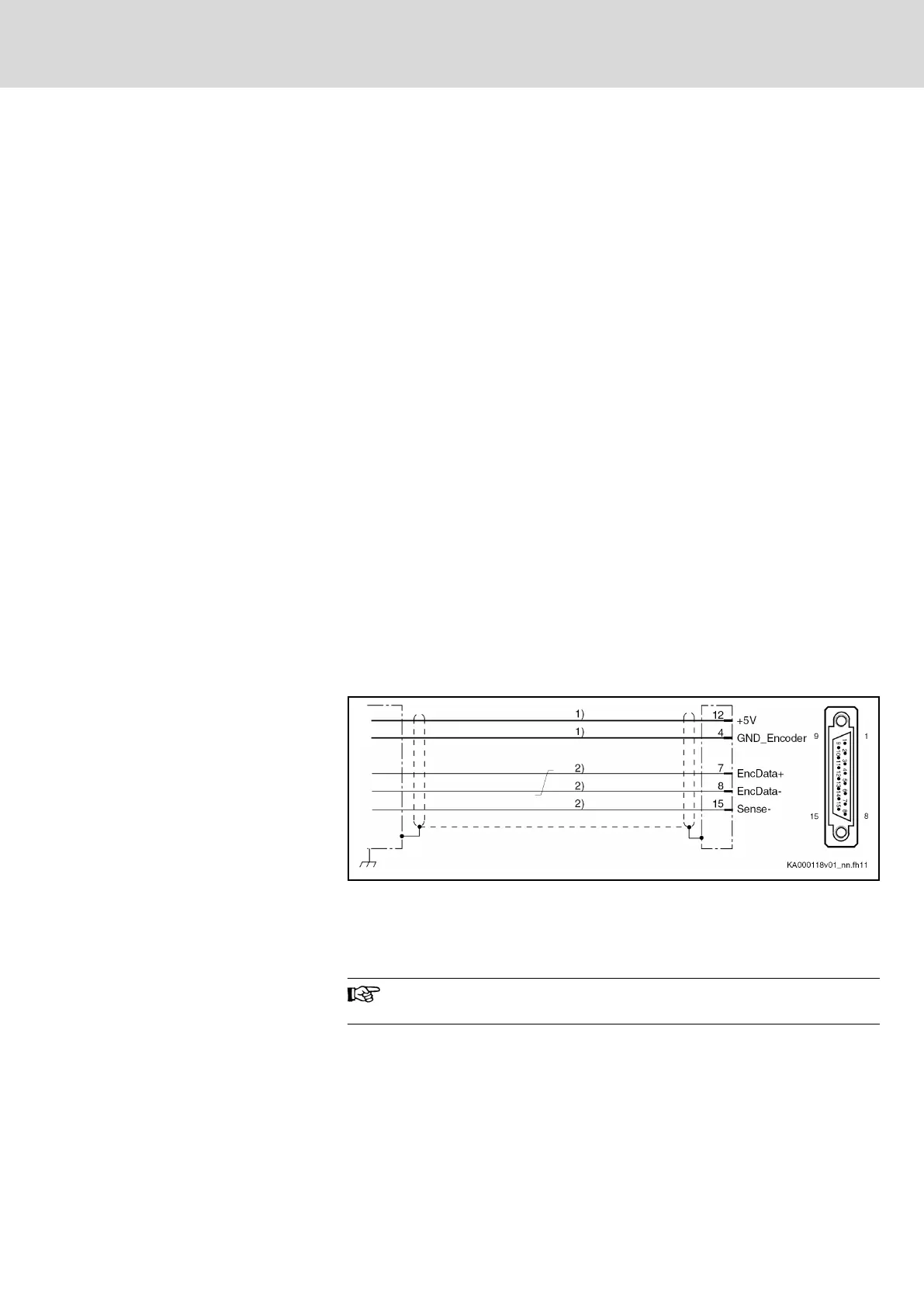

Connection diagram

1) Line cross section ≥ 0.5 mm²; observe allowed encoder cable

length

2) Line cross section ≥ 0.14 mm²

Fig. 8-1: EC connection diagram with encoder system of IndraDyn S MSM mo‐

tors

For direct

connection to the encoder system, use our RKG0033

cable.

Power supply

5 V (the voltage is made available via the EC interface)

Technical

specification of the power supply: See chapter "5 V power supply"

on page 92

Cable length

40 m at most

DOK-INDRV*-CXX02******-PR03-EN-P Bosch Rexroth AG 79/143

IndraDrive Control Sections CSB02, CSE02, CSH02, CDB02

Technical data - functions

Courtesy of CMA/Flodyne/Hydradyne ▪ Motion Control ▪ Hydraulic ▪ Pneumatic ▪ Electrical ▪ Mechanical ▪ (800) 426-5480 ▪ www.cmafh.com

Loading...

Loading...