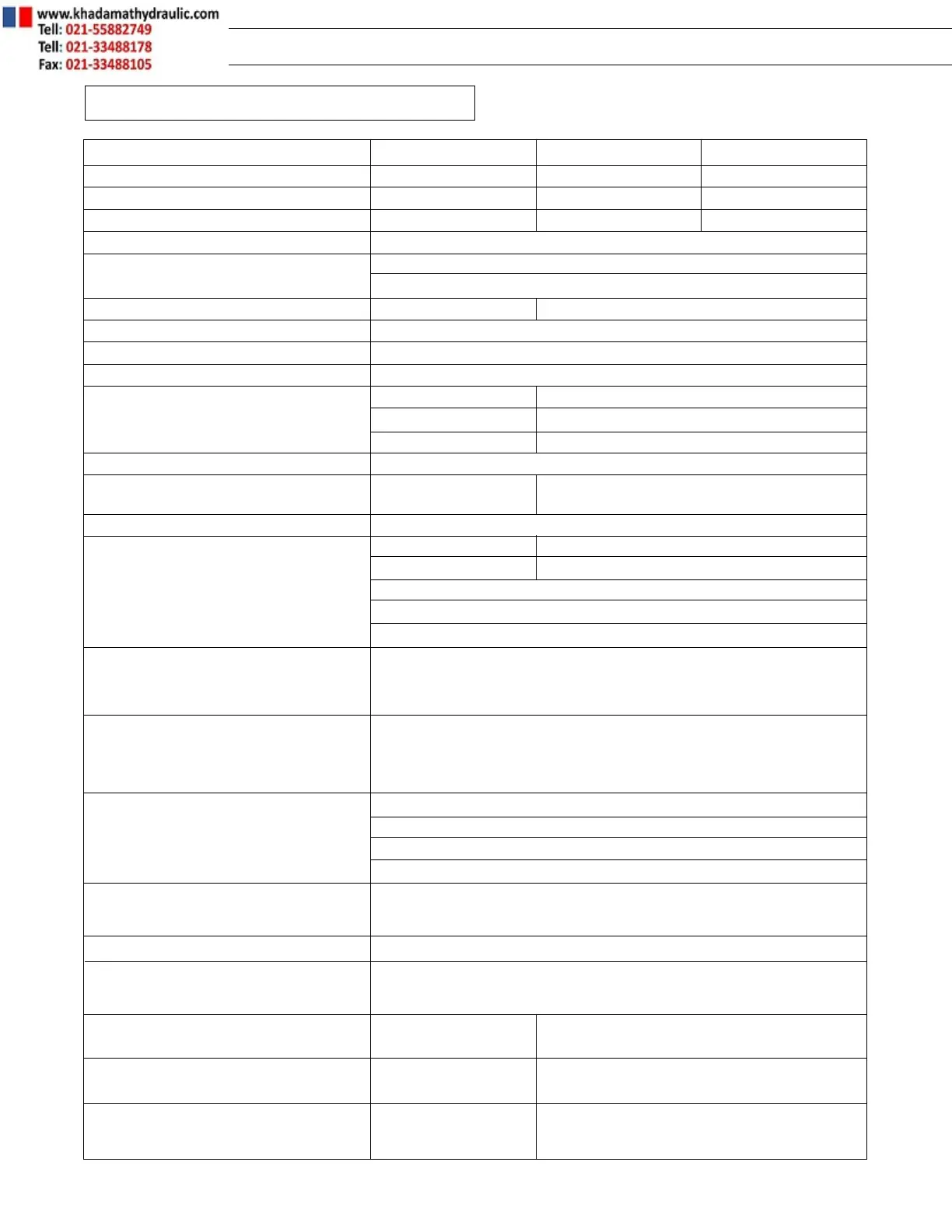

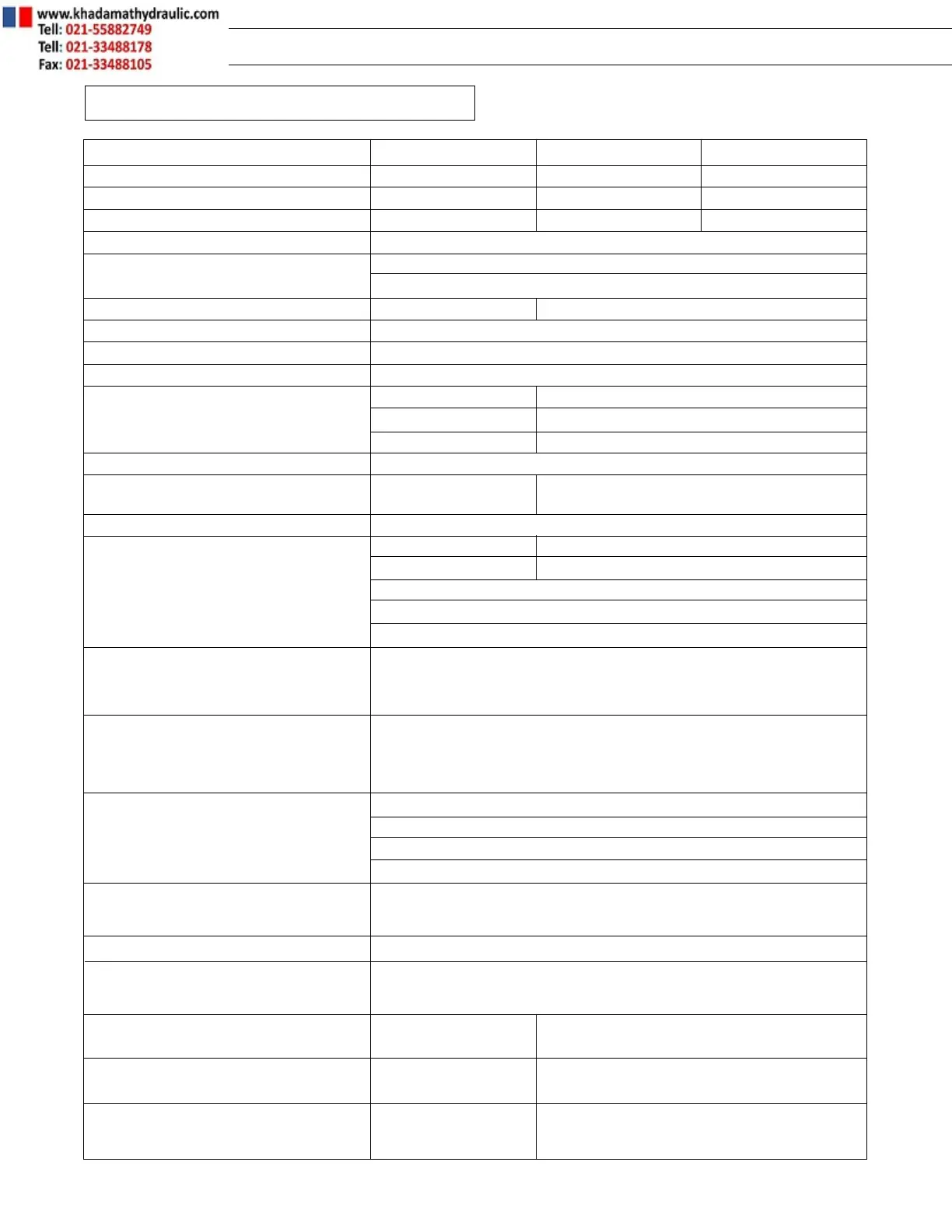

VPV Vane Pump 3

Specifications

General VPV 16 VPV 25 VPV 32

Displacement (Nominal) 1 in

3

/rev (16 cm

3

/rev) 1.5 in

3

/rev (25 cm

3

rev) 2 in

3

/rev (32 cm

3

/rev)

Displacement (Actual) 1.06 in

3

/rev (16.8 cm

3

/rev) 1.66 in

3

/rev (27.4 cm

3

rev) 2.04 in

3

/rev (32 cm

3

/rev)

Flow at 1750 RPM

1

7.57 GPM (28.6 L/min) 11.36 GPM (43.0 L/min) 15.15 GPM (57.3 L/min)

Maximum continuous pressure 3000 psi (210 bar)

Pressure compensating Single stage 200-3000 psi (14-210 bar) Minimum pressure of 190 PSI

range Two stage 300-3000 psi (20-210 bar) Minimum pressure of 290 PSI

Maximum transient spike pressure 3800 psi (260 bar) 4000 psi (280 bar)

Maximum case pressure 10 psi (0.7 bar)

Speed range 1150-1800 RPM

Direction of rotation (viewed from shaft end) Right hand (clockwise)

Case drain flow 1000 psi (70 bar) 0.6 GPM (2.3 L/min) 0.6 GPM (2.3 L/min)

while compensating 2000 psi (140 bar) 0.9 GPM (3.4 L/min) 1.1 GPM (4.2 L/min)

@ 1800 RPM 3000 psi (210 bar) 1.26 GPM (4.8 L/min 1.4 GPM (5.3 L/min)

Maximum inlet vacuum at sea level 6 in. HG (152 mm HG)

Mounting

2

- SAE 2-bolt flange (ISO 3019/1) S.A.E. ‘A’ S.A.E. ‘B’

2-bolt flange 2-bolt flange

Mounting Position Unrestricted

Inlet #16 S.A.E. #24 S.A.E

Outlet #12 S.A.E. #16 S.A.E.

Port sizes Case drain #8 S.A.E.

Clipper control drain (optional) #6 S.A.E.

Remote control (optional) #4 S.A.E.

Drive Pump to be connected to prime mover by means of a flexible coupling that is aligned

to a maximum of .006” (.152mm) total indicator reading. No overhung or side loads

permitted. Alignments greater than .006” indicator reading could cause increased

noise and vibration as well as premature shaft seal wear resulting in leakage.

Fluid recommendations A premium quality hydraulic oil with anti-wear additives is recommended, but not

required. Refer to publication S-106 “Petroleum Hydraulic Fluids” for a list of fluids

which meet or exceed the necessary lubrication requirements. Consult factory for

use with water base fire resistant fluids.

Minimum 100 SUS (21 cSt)

Fluid viscosity at Maximum 1000 SUS (216 cSt)

operating temperature Optimum 150-250 SUS (32-54 cSt)

Maximum start-up 4000 SUS (864 cSt)

Fluid temperature Normal inlet fluid temperature should not exceed 140°F (60° C). Always select a fluid

for optimum viscosity at operating temperature. Consult factory for applications assis-

tance when inlet fluid temperatures over 140° F (60° C) are expected.

Seals Fluorocarbon Standard

Filtration Fluid cleanliness per ISO/DIS 4406 should be 18/15 or better for pressures of 2000 psi or

less. For continuous operating pressures of 2000 to 3000 psi, fluid cleanliness should be

17/13 or better.

Response time Full flow to 20-35 ms 20-35 ms

(circuit dependent) minimum flow

Recovery time Minimum flow 50-135 ms – 70-185 ms –

(circuit dependent) to full flow single stage compensator single stage compensator

Weight Single stage 34 lbs. (16.5 kg) 61 lbs. (28 kg)

Two stage 38 lbs. (17.3 kg) 65 lbs. (28.5 kg)

1

Flows are actual. Volumetric efficiencies shown in technical data taken into account.

2

Metric

4-bolt flange

available

(ISO 3019/2)

available. Please consult factory.

Loading...

Loading...