1)

after the first run under load conditions, likewise after each wheel change.

2)

under extreme conditions, increase frequency (e.g. construction sites and poor roads).

3)

for use outside Europe

MMaaiinntteennaannccee wwoorrkk

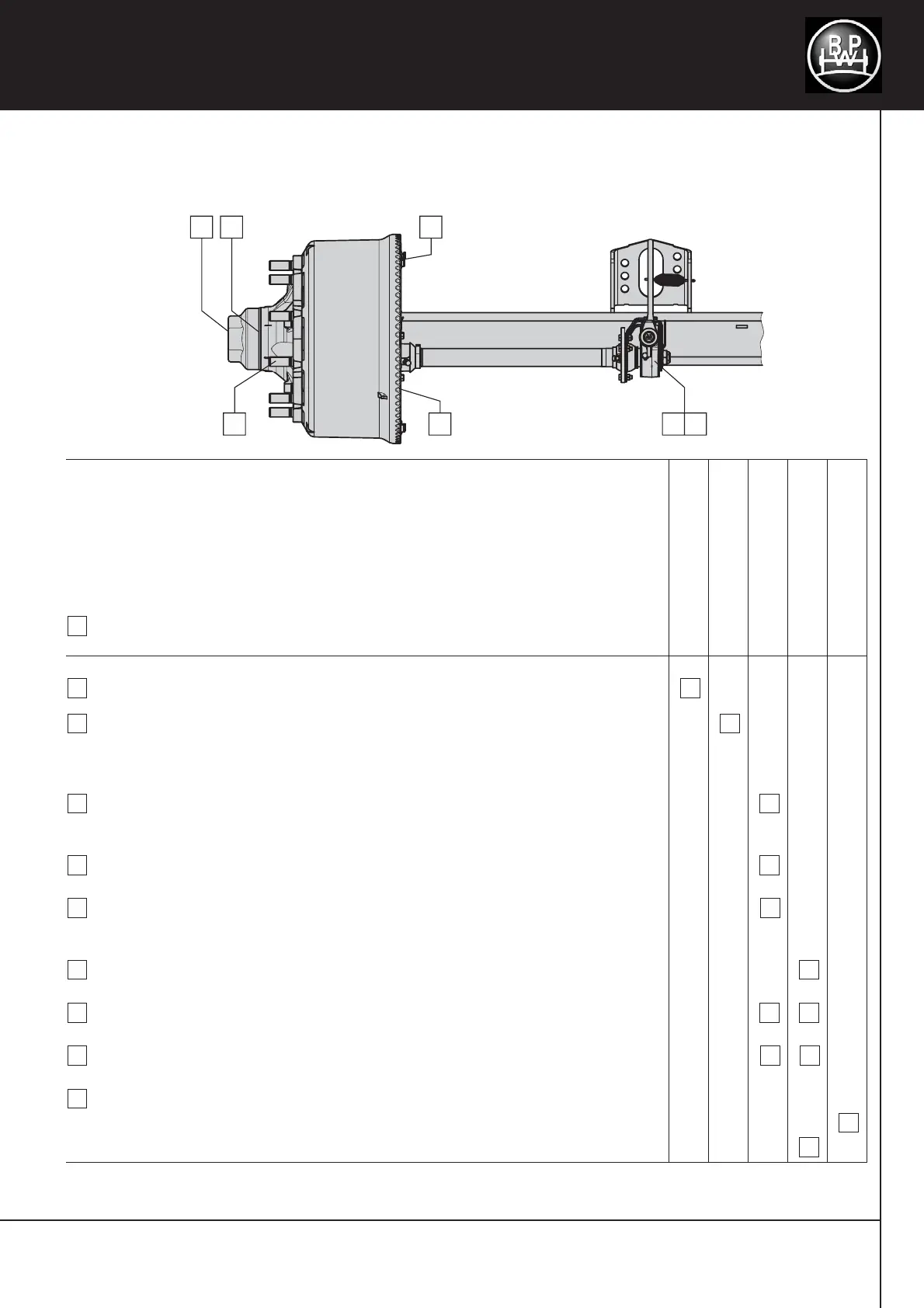

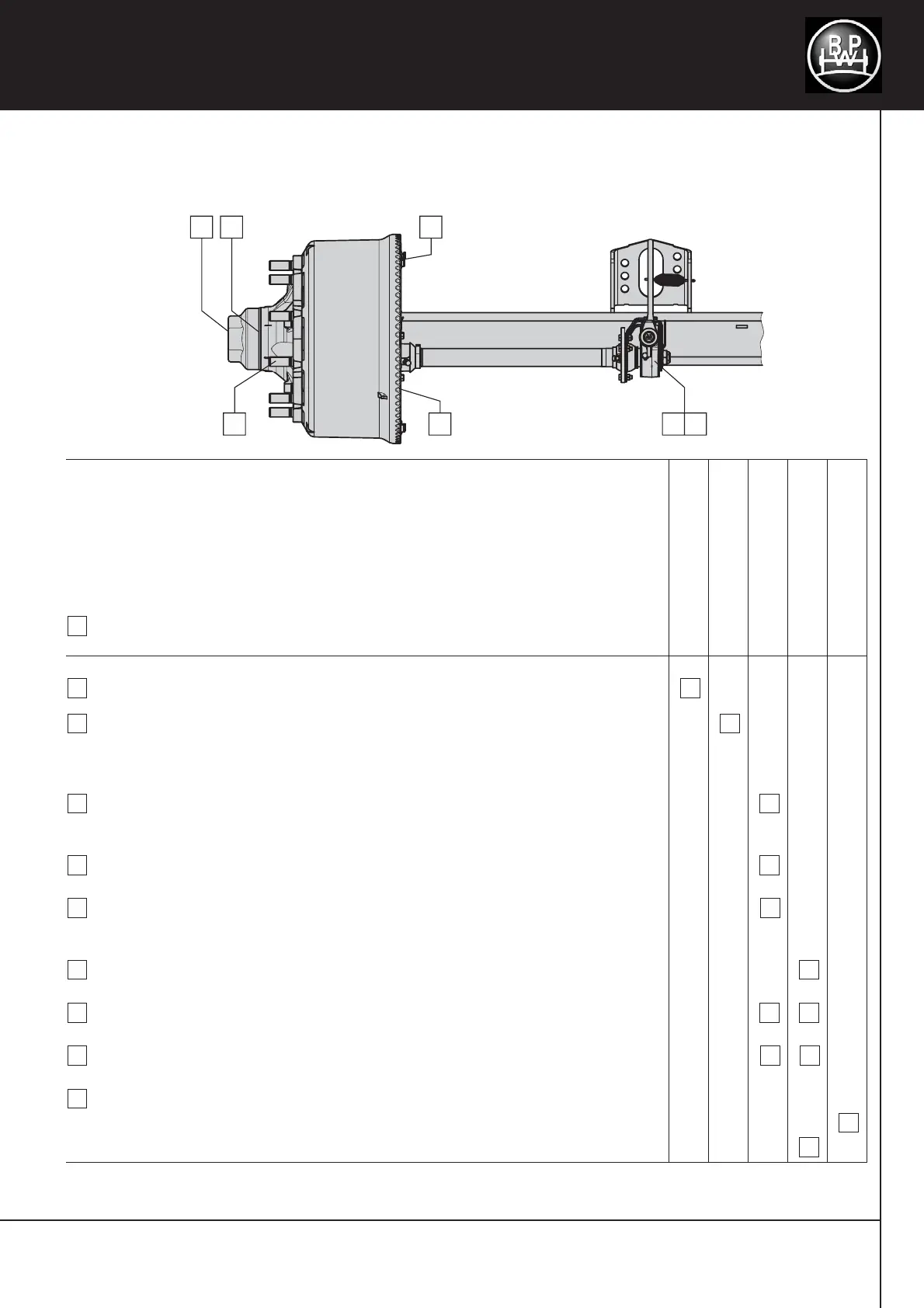

Overview

For detailed description, see pages 37 to 311

Maintenance

1 Check wheel nuts for tightness. 1

2 With manual slack adjusters, check brake play, adjust if necessary to 10 12% 2

of the connected brake lever length and activate by hand or with 0.5 0.8 bar.

(Not applicable in the case of automatic slack adjusters.)

3 Check brake lining thickness. Brake lining thickness at least 5 mm or check 3

wear indicator. (Cam brake N 3006 min. 2.5 mm residual lining thickness).

4 Check the brake drum internal diameter. 4

– Check the tyres for uneven wear, adjust the inflation pressure if necessary –

according to the manufacturer's specifications.

5 Check hub caps for firm seating. (not necessary with ECO

Plus

axles) 5

6 Check operation of automatic slack adjusters. 66

– Visual inspection of all component parts for damage and wear. ––

7 Check wheel hub bearing play, adjust if necessary.

ECO

Plus

hub bearing 7

ECO hub bearing, conventional bearing 7

3)

1)

3)

Loading...

Loading...