Model 871A User’s Manual LASER INPUT

Bristol Instruments, Inc. 11

1 Ensure that all fiber-optic connectors are clean and dry. The 871 system is shipped

with a fiber cleaning kit consisting of a package of connector cleaning sticks, clean

wipes, and fiber-optic splice & connector cleaner spray. See Appendix F for cleaning

instructions.

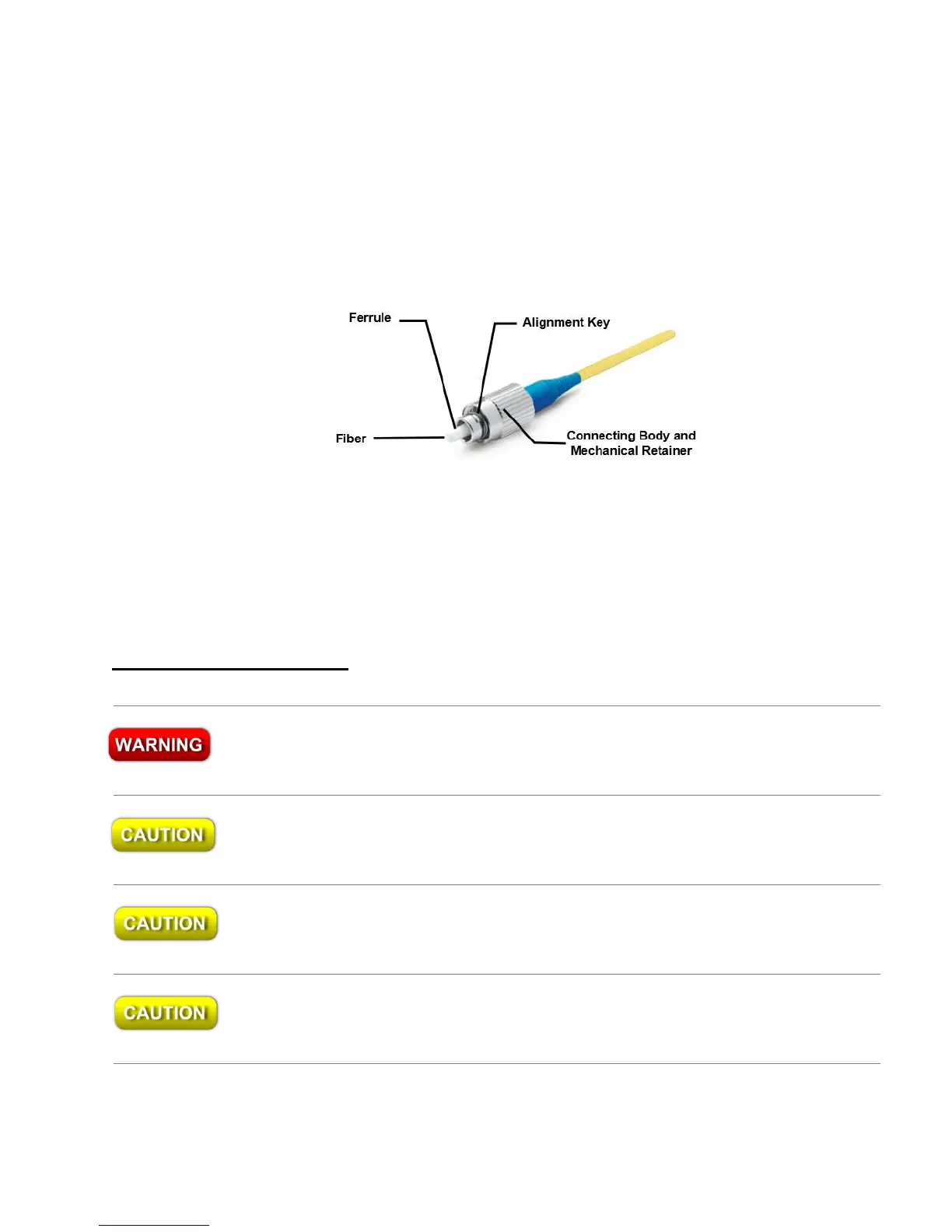

2 Connect your fiber-optic patchcord to the pre-aligned FC/PC fiber-optic connector on

the instrument’s front panel. Make certain that the alignment key on the fiber-optic

patchcord’s connector (Figure 3.2) is properly seated in the slot of the input

connector.

Figure 3.2: Basic Components of an FC/PC Fiber-Optic Connector

3 Tighten the mechanical retainer with a light to medium finger-tightness. Exceeding

this torque may result in a poor connection or may damage the connector.

Free-Beam Laser Input

Never inspect or clean a fiber-optic cable without first disconnecting the entire

cable assembly from the optical source. Failure to take this precaution can

permanently damage your eyesight.

Use care in handling fiber-optic connectors. Always clean the fiber end prior to insertion

into the instrument’s fiber-optic connector for optimum performance. Failure to do so can

result in damage to the instrument.

Maximum safe input for the 871 Series Laser Wavelength Meter is 10 mW of CW or time-

averaged optical power, or 0.5 mJ of pulsed laser energy (10 ns pulse). Laser input

power in excess of these values can result in damage to the instrument.

Maximum safe input for the BC-1 Series is limited by the fiber-optic patch cord connected

to the BC-1. Refer to the maximum optical power and laser energy specifications

provided by the fiber-optic patch cord manufacturer.

Loading...

Loading...