Model 871A User’s Manual USING THE LASER WAVELENGTH METER

Bristol Instruments, Inc. 17

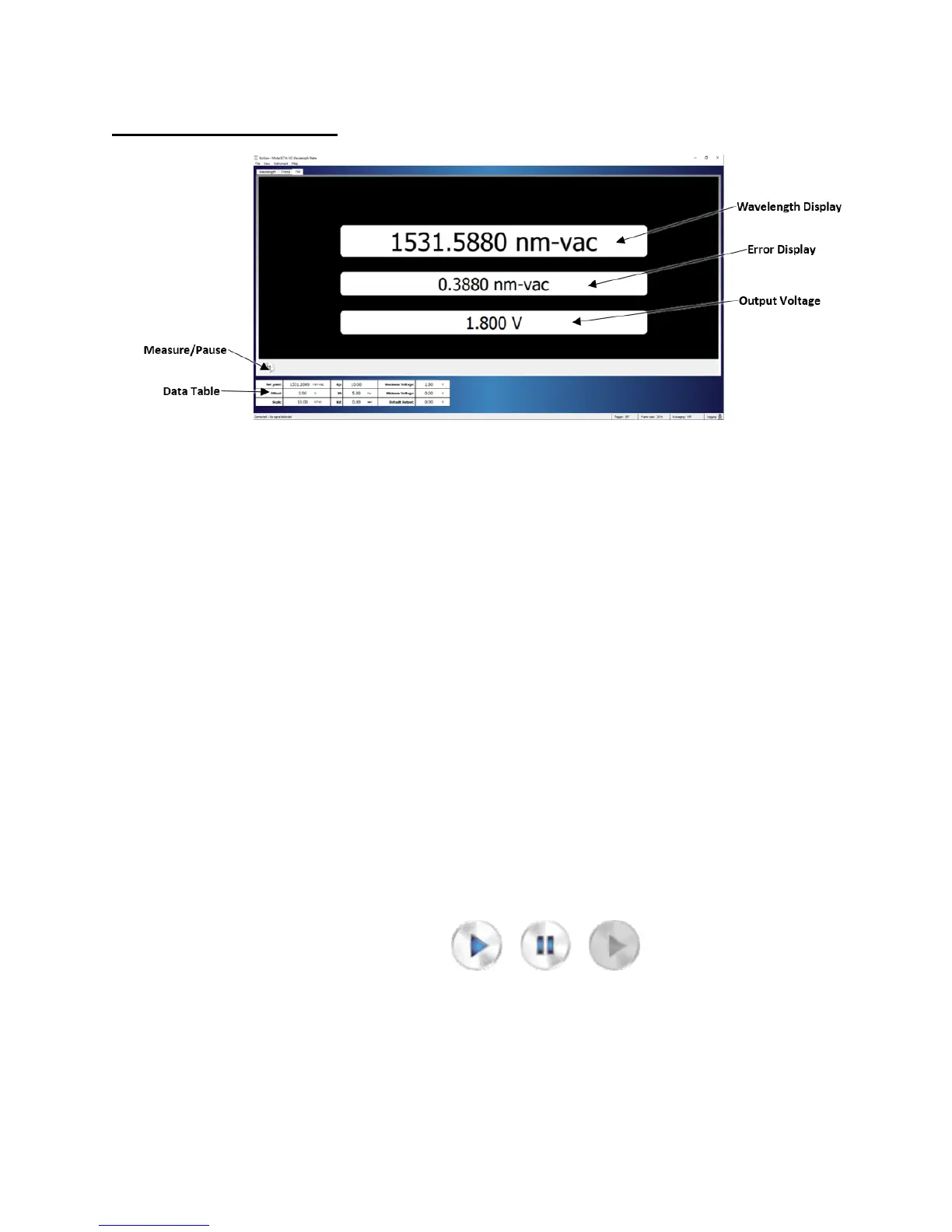

PID Controller Screen

Figure 4.5: PID Controller Screen

The PID Controller Screen displays the settings for the 871-system’s internal PID

controller and reports the most recent wavelength reading and output voltage supplied

through the Analog Out BNC connector on the back panel of the wavelength meter

(Figure 2.1).

The calculation behind the PID Controller Screen consists of three separate voltage

parameters input by the user. The first parameter, K

p

, accounts for the current

(Proportional) error magnitude and has the highest contribution to guiding the measured

wavelength towards the set point. The second parameter, K

i

, accounts for the sum of

past errors (Integral) to minimize the effects of outlying data peaks or spikes on the

correction voltage. The third parameter, K

d

, factors in the current rate of change

(Derivative) to avoid oscillation about the desired wavelength. These three components

ensure swift correction of the laser to the desired frequency with minimal overshooting or

oscillation.

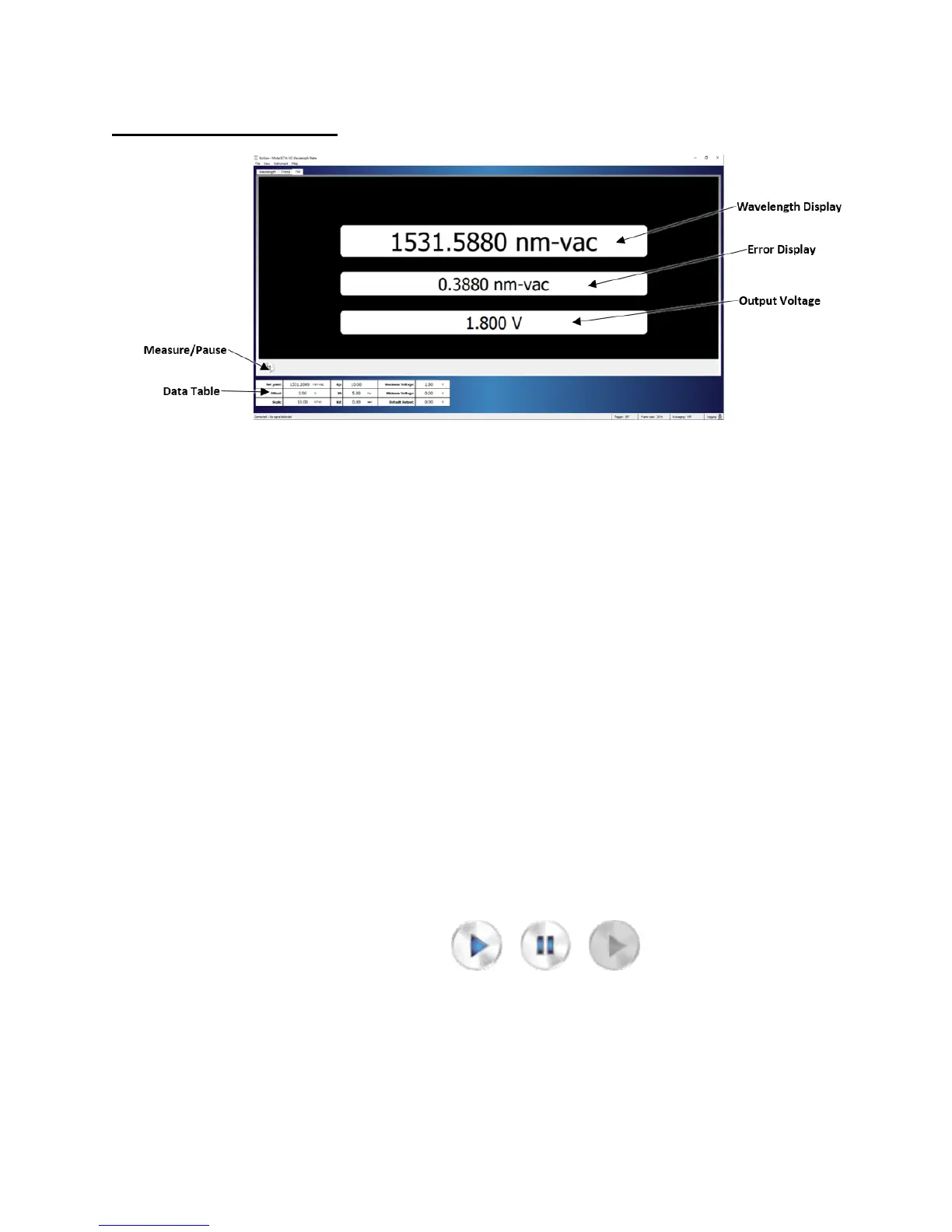

Measure/Pause

Enables the PID calculations to determine the output voltage. Selecting the

Measure button (left) initiates the PID calculation. After the Measure button is

selected, it changes its appearance to the Pause button (middle). The PID

calculation updates continuously until the Pause button is selected. Selecting the

Pause button stops data collection. When the instrument is not connected, the

Measure button changes its appearance to its greyed-out inactive state (right).

Loading...

Loading...