BRUNSWICK INSTALLATION MANUALPAGE 13

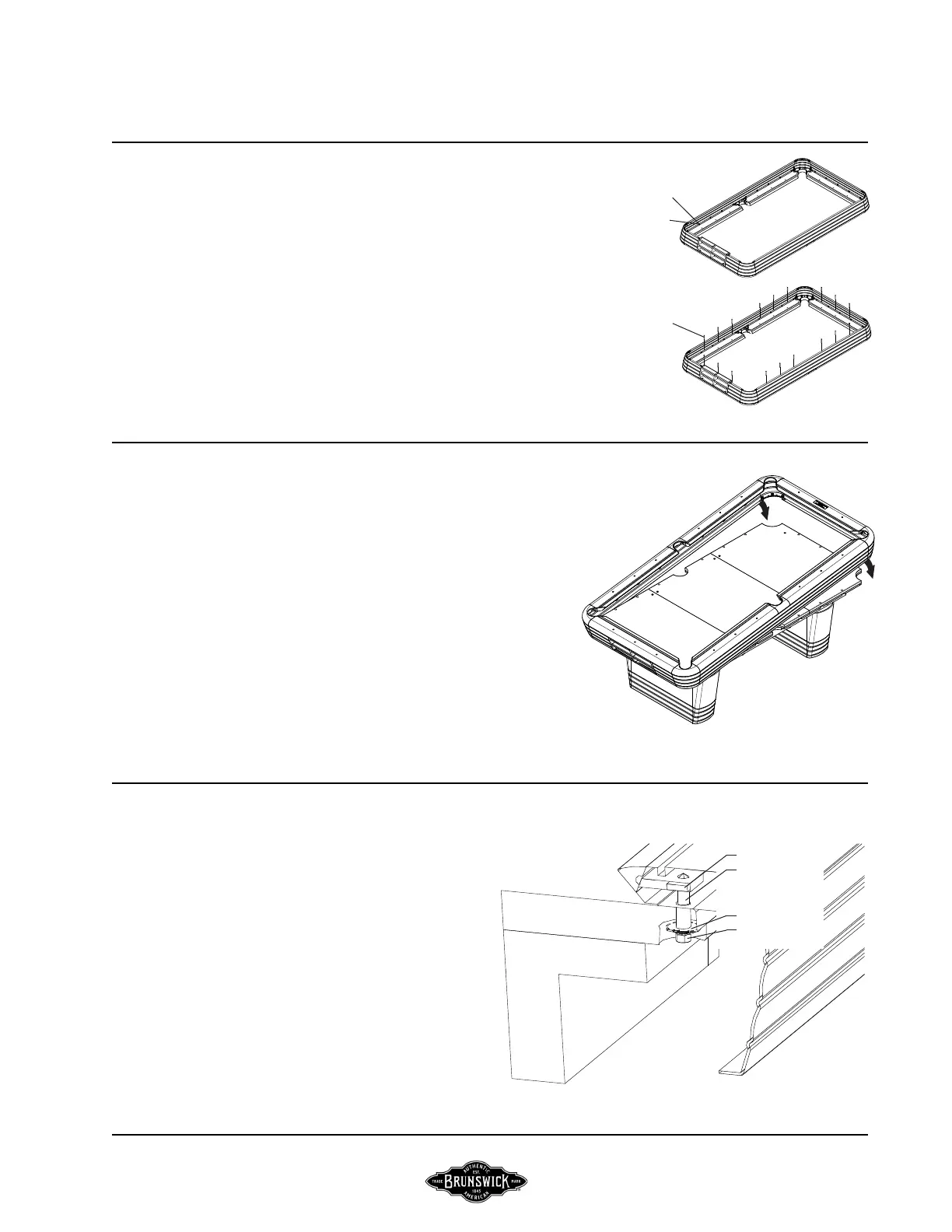

FIGURE FOUR

APRONS, APRON CORNERS

AND BALL STORAGE RACK ASSEMBLY

Step #6: At this time, tighten all apron ange attach fasteners that

have been left loose.

Step #7: Thread all eighteen 3/8-16 x 2 3/4 machine studs into

each location on the bottom surface of the six rails. Thread machine

studs in until contact with wood is made and then loosen 1/4 turn.

This will allow for free movement of the stud and internal nut plate.

FIGURE FIVE

Step #8: Carefully turn the rail and apron assembly over and lower over

the table. Finger clearance between bottom edge of aprons and slate is

limited, therefore, shift toward one end and lower that end over the

slate rst, then shift in the opposite direction and lower the other end

over the slate. All eighteen machine studs must be aligned with the

clearance holes in the slate during this process.

CAUTION: Do not allow excessive weight to be applied to wood

components when turning the assembly over, the strain may

cause damage.

FIGURE FOUR

FIGURE FIVE

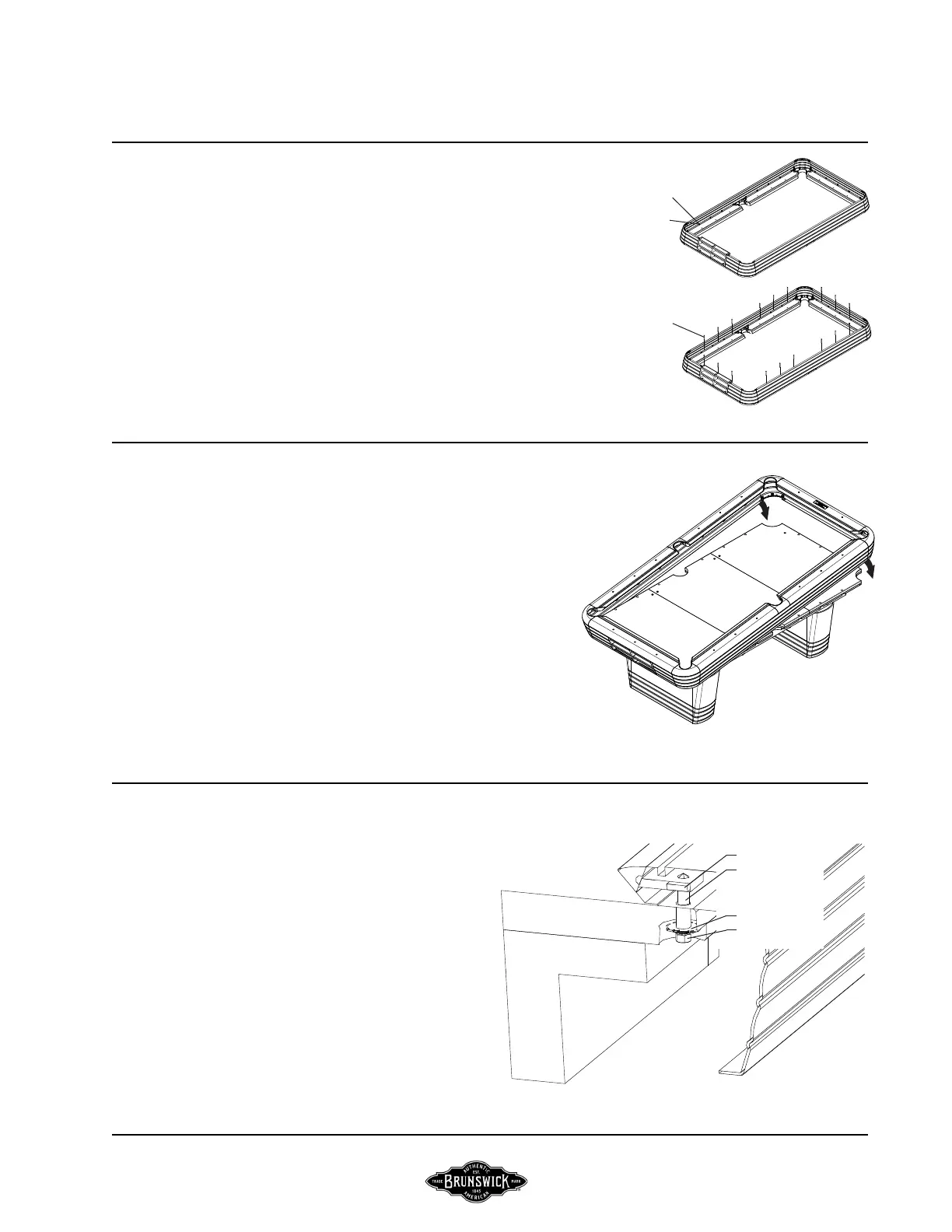

FIGURE SIX

FIGURE SIX

Step #9: Thread the hex nut and dome washer onto all eighteen

machine studs. Center entire rail and apron assembly across width

and length of the slate and tighten to a recommended torque of

15 ft/lbs.

3/8-16 x 2-3/4

MACHINE STUD

CENTENNIAL

5/16-18 x 2 HEX

HEAD SCREW

5/16 WASHER

SLAT

E

F

R

AM

E

MACHINE STUD

NUT PLATE

3/8-16 NUT

DOMED WASHER

Loading...

Loading...