926SB: Installation, Start-up, Operating, Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

44

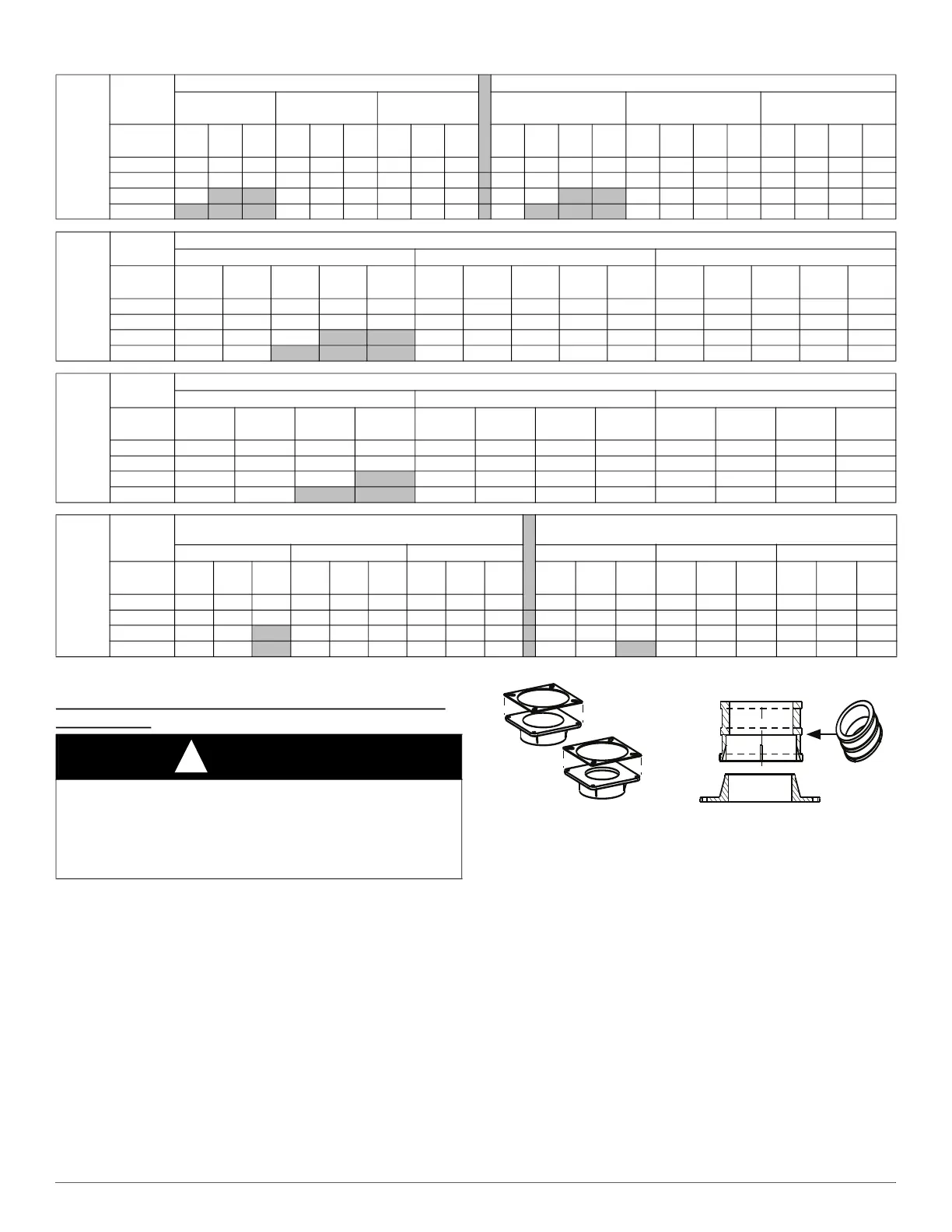

Maximum Allowable Exposed Vent Length in Unconditioned Space (Metric)

* Pipe length (ft) specified for maximum pipe lengths located in unconditioned spaces. Pipes located in unconditioned space cannot exceed total allowable pipe length calculated from Table 15.

† Insulation thickness based on R value of 3.5 per in.

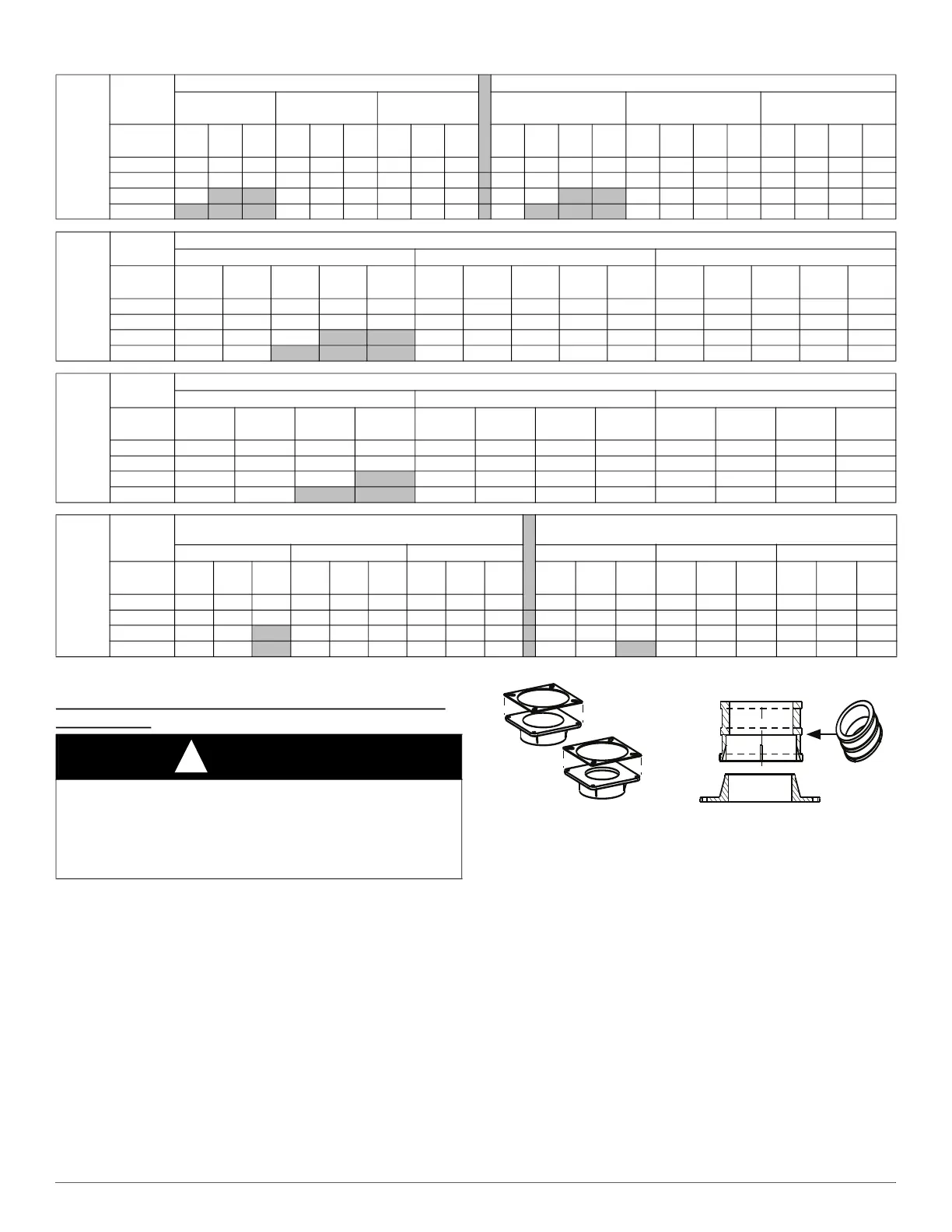

Installing the Vent Pipe Adapter and Combustion Air

Pipe Adapter

NOTE: The rubber coupling that attaches to the vent pipe adapter must

be used. The adapter seals the vent pipe to the casing and reduces the

strain on the vent elbow attached to the inducer.

1. Apply the gaskets to the vent pipe and combustion air pipe

adapters. If supplied, remove and discard round center “slug” from

interior of gasket. See Fig. 58.

A13074

Fig. 58 – Vent Coupling and Adapter with Gaskets

NOTE: The vent pipe adapter can be distinguished from the inlet pipe

adapter by the absence of an internal pipe-stopping ring. The vent pipe

can pass through the vent pipe adapter; it cannot pass through the inlet

pipe adapter.

2. Align the screw holes in the plastic vent pipe adapter with the

dimples in the casing.

Winter

Design

Temp

°C

Unit Size

40,000* BTUH

60,000 BTUH

Uninsulated

3/8-in.

Insulation

1/2-in.

Insulation

Uninsulated 3/8-in. Insulation 1/2-in. Insulation

Pipe Dia.

mm

38 51 64 38 51 64 38 51 64 38 51 64 76 38 51 64 76 38 51 64 76

-7 6.1 6.1 6.1 6.1 15.2 13.7 6.1 18.3 15.2 6.1 9.1 9.1 7.6 6.1 22.9 19.8 18.3 6.1 25.9 22.9 19.8

-18 3.0 1.5 1.5 6.1 7.6 6.1 6.1 9.1 7.6

4.6 4.6 3.0 3.0 6.1 12.2 9.1 7.6 6.1 13.7 12.2 9.1

-29 1.5 6.1 4.6 3.0 6.1 6.1 4.6 3.0 1.5 6.1 7.6 6.1 4.6 6.1 9.1 7.6 6.1

-40

4.6 3.0 1.5 4.6 4.6 3.0 1.5 6.1 4.6 4.6 3.0 6.1 6.1 4.6 3.0

Winter

Design

Temp

°C

Unit Size

80,000 BTUH

Uninsulated 3/8-in. Insulation 1/2-in. Insulation

Pipe Dia.

mm

38 51 64 76 102 38 51 64 76 102 38 51 64 76 102

-7 4.6 12.2 12.2 10.7 9.1 4.6 15.2 27.4 22.9 19.8 4.6 15.2 21.3 21.3 21.3

-18 4.6 6.1 4.6 3.0 1.5 4.6 15.2 13.7 10.7 9.1 4.6 15.2 15.2 12.2 10.7

-29 4.6 3.0 1.5

4.6 10.7 9.1 6.1 4.6 4.6 12.2 9.1 7.6 4.6

-40 3.0 1.5 4.6 7.6 6.1 4.6 1.5 4.6 9.1 7.6 6.1 3.0

Winter

Design

Temp

°C

Unit Size

100,000 BTUH

Uninsulated 3/8-in. Insulation 1/2-in. Insulation

Pipe Dia.

mm

51 64 76 102 51 64 76 102 51 64 76 102

-7 6.1 15.2 12.2 10.7 6.1 24.4 28.9 24.4 6.1 24.4 32.0 27.4

-18 6.1 6.1 4.6 3.0 6.1 16.8 13.7 10.7 6.1 19.8 16.7 13.7

-29 4.6 3.0 1.5

6.1 10.7 9.1 6.1 6.1 13.7 10.7 7.6

-40 3.0 1.5

6.1 7.6 6.1 3.0 6.1 9.1 7.6 4.6

Winter

Design

Temp

°C

Unit Size

120,000 BTUH

140,000 BTUH

Uninsulated 3/8-in. Insulation 1/2-in. Insulation Uninsulated 3/8-in. Insulation 1/2-in. Insulation

Pipe Dia.

mm

64 76 102 64 76 102 64 76 102 64 76 102 64 76 102 64 76 102

-7 3.0 15.2 12.2 3.0 22.9 28.9 3.0 22.9 32.0 1.5 16.7 15.2 1.5 19.8 32.0 1.5 19.8 38.1

-18 3.0 6.1 4.6 3.0 16.8 13.7 3.0 19.8 15.2

1.5 7.6 4.6 1.5 19.8 15.2 1.5 19.8 18.3

-29 3.0 3.0

3.0 10.7 7.6 3.0 13.7 9.1 1.5 3.0 1.5 1.5 13.7 9.1 1.5 15.2 12.2

-40 3.0 1.5

3.0 7.6 4.6 3.0 9.1 6.1 1.5 1.5 1.5 9.1 6.1 1.5 35 7.6

WARNING

!

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal injury or death.

DO NOT use cement to join polypropylene venting systems. Follow

the polypropylene venting system manufacturer’s instructions for

installing polypropylene venting systems.

Attach gaskets to vent pipe and

combustion air adapters.

Vent Coupling and Adapter

Loading...

Loading...