926SB: Installation, Start-up, Operating, Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

45

3. Pilot drill the screw holes for the adapter in the casing and attach

the vent pipe adapter to the furnace with sheet metal screws.

4. Slide the end of the rubber vent coupling with notches in it over the

standoffs on the vent pipe adapter.

5. Insert a length of vent pipe through the coupling into the outlet of

the vent elbow.

6. Tighten the clamp around the outlet of the vent elbow. Torque the

clamp to 15 lb-in.

Install the remaining vent and combustion air pipes as shown below. It is

recommended that all pipes be cut, prepared, and pre-assembled before

permanently cementing any joint.

1. Working from furnace to outside, cut pipe to required length(s).

2. De-burr inside and outside of pipe.

3. Chamfer outside edge of pipe for better distribution of primer and

cement.

4. Clean and dry all surfaces to be joined.

5. Check dry fit of pipe and mark insertion depth on pipe.

6. Insert the vent pipe into the vent elbow.

7. Torque clamp on vent elbow 15 lb-in.

8. Torque clamp on vent coupling 15 lb-in.

9. Insert the combustion air pipe into the adapter.

10. Pilot drill a screw hole through the adapter into the combustion air

pipe and secure the pipe to the adapter with sheet metal screws. DO

NOT DRILL INTO POLYPROPYLENE VENT PIPES. Use an

optional accessory vent coupling, if needed.

11. Seal around the combustion air pipe with silicone or foil tape.

SILICONE SEALERS MAY NOT BE APPROPRIATE FOR

POLYPROPYLENE VENT SYSTEMS. SEE

POLYPROPYLENE VENT SYSTEM MANUFACTURER’S

INSTRUCTIONS.

12. After pipes have been cut and pre-assembled, apply generous layer

of cement primer to pipe fitting socket and end of pipe to insertion

mark. Quickly apply approved cement to end of pipe and fitting

socket (over primer). Apply cement in a light, uniform coat on

inside of socket to prevent buildup of excess cement. Apply second

coat. DO NOT CEMENT POLYPROPYLENE FITTINGS.

13. While cement is still wet, twist pipe into socket with 1/4-in. turn.

Be sure pipe is fully inserted into fitting socket.

14. Wipe excess cement from joint. A continuous bead of cement will

be visible around perimeter of a properly made joint.

15. Handle pipe joints carefully until cement sets.

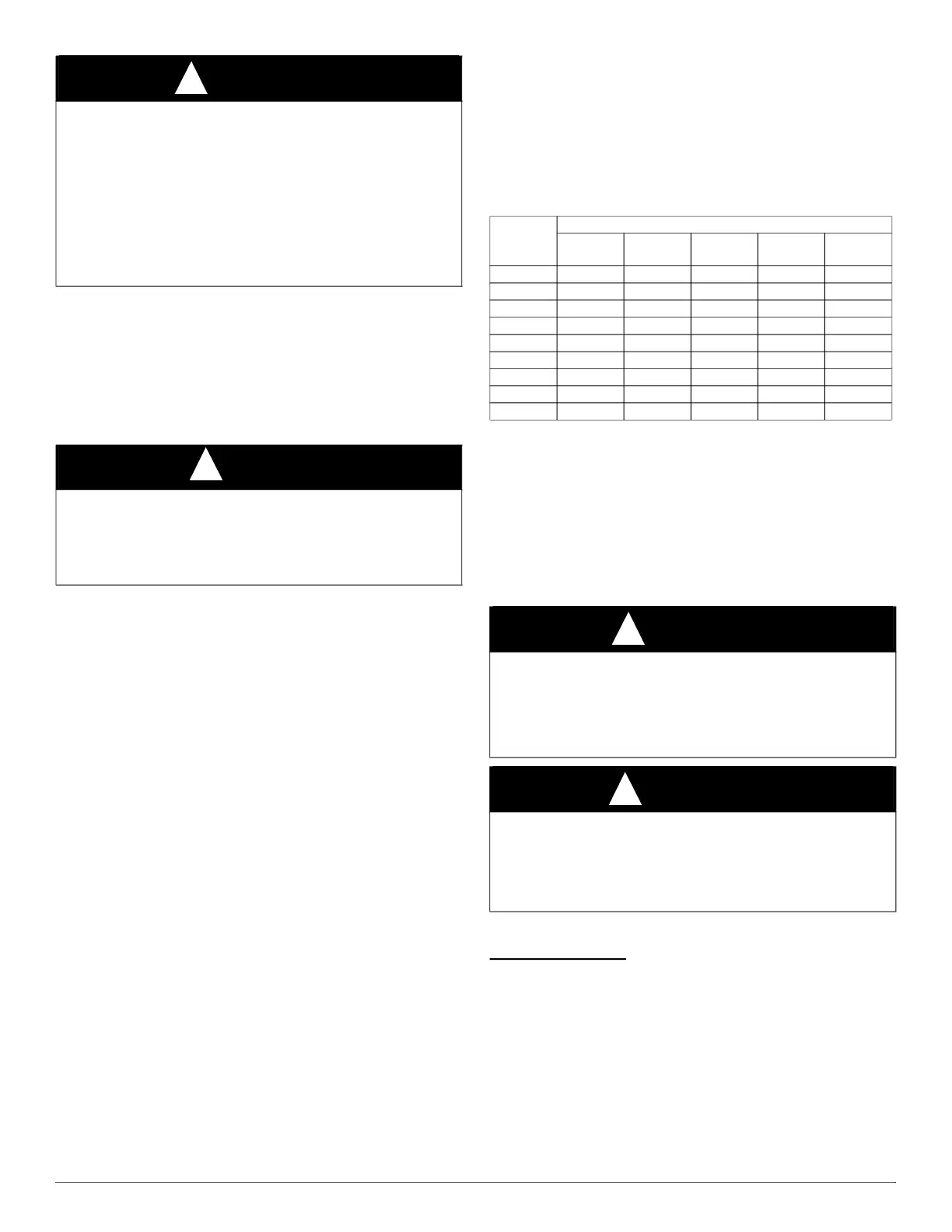

16. Horizontal portions of the venting system shall be supported to

prevent sagging. Space combustion air piping and vent piping

hangars as shown in Table 18. Support pipes using perforated metal

hanging strap or commercially available hangars or straps designed

to support plastic pipe.

Table 18 – Hanger Spacing

17. Slope the vent and combustion air piping downward towards

furnace. A minimum slope of at least 1/4-in. (6 mm) per linear

ft.(1-in (25 mm) per 4 ft.(1.2 M)) with no sags between hangers is

required. See Caution Box below. Complete the vent and

combustion air pipe installation by connecting the concentric vent

or by installing the required termination elbows as shown in

Fig. 40, Fig. 41 and Fig. 49. For Ventilated Combustion Air

Termination, see Fig. 48.

18. Use appropriate methods to seal openings where combustion air

pipe and vent pipe pass through roof or sidewall.

Installing the Vent Termination

Roof Terminations

A roof termination of any type will require a 4-in. (102 mm) flashing for

a 2 in. (50 mm ND) concentric vent kit, KGAVT0701CVT or a 5-in.

diameter (127 mm) flashing for a 3-in. (80 mm ND) concentric vent kit,

KGAVT0801CVT. For two-pipe or single pipe vent systems, a flashing

for each pipe of the required diameter will be necessary.

It is recommended that the flashing be installed by a roofer or competent

professional prior to installing the concentric vent. The terminations can

be installed on a flat or pitched roof.

WARNING

!

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal injury or death.

To route the vent pipe and combustion air pipe through the furnace, the

manufacturer supplied kit must be used. Failure to properly seal the

blower compartment from the furnace vestibule could result in the

circulation of carbon monoxide throughout the structure. The vent pipe

and combustion air pipe must be a continuous pipe while passing

through the blower compartment. Seals supplied in this kit must be

installed per the instructions provided. Follow all procedures outlined

in these instructions.

NOTICE

!

The following instructions are for PVC/ABS DWV vent piping only.

DO NOT USE THESE TECHNIQUES FOR POLYPROPYLENE

VENT PIPING SYSTEMS. See the polypropylene vent system

manufacturer’s instructions for installing polypropylene venting

systems.

Diameter

Material

PVC Sch

40

SDR 21 &

26

ABS CPVC

Polyprop

ylene

1 1/2-in.

3-ft. 2 1/2-ft. 3-ft. 3-ft. 3.25-ft.

38-mm

914-mm 762-mm 914-mm 914-mm 1000 mm

2-in.

3-ft. 3-ft. 3-ft. 3-ft. 3.25-ft.

51-mm

914-mm 914-mm 914-mm 914-mm 1000 mm

2 1/2-in.

3 1/2-ft. 3-ft. 3 1/2-ft. 3 1/2-ft. 3.25-ft.

64-mm

1067-mm 914-mm 1067-mm 1067-mm 1000 mm

3-in.

3 1/2-ft. 3-ft. 3 1/2-ft. 3 1/2-ft. 3.25-ft.

76-mm

1067-mm 914-mm 1067-mm 1067-mm 1000 mm

4-in.

4-ft. 3 1/2-ft. 4-ft. 4-ft. 3.25-ft.

CAUTION

!

FURNACE RELIABILITY HAZARD

Failure to follow this caution may result in nuisance short cycling,

frozen vent termination, and/or no heat.

Slope the vent and combustion air piping downward towards furnace a

minimum of 1/4-in. (6 mm) per linear ft. of pipe.

WARNING

!

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal injury or death.

DO NOT use cement to join polypropylene venting systems. Follow

the polypropylene venting system manufacturer’s instructions for

installing polypropylene venting systems.

Loading...

Loading...