Do you have a question about the Buchi Pure C-810 and is the answer not in the manual?

Details on danger levels and signal words used in warnings within the manual.

Explanation of warning symbols and mark-ups used in the operation manual and on the device.

Information regarding product names and registered or unregistered trademarks.

Instructions and specifications for connected devices, to be followed alongside operating instructions.

Defines the intended use of the instrument and its permissible tasks in a laboratory setting.

Lists applications that are not permissible and constitute use other than intended.

Specifies the necessary qualifications for users and operators to safely handle the device.

Identifies the location of warning signs on the product for hazard awareness.

Details residual risks like faults during operation, malware, and memory damage.

Guidelines for wearing appropriate personal protective equipment during operation.

Information on unauthorized modifications and BUCHI's liability for them.

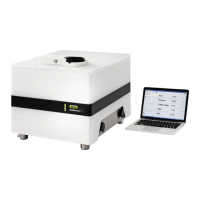

Describes the Pure instruments' capabilities for flash and prep chromatography.

Illustrates front and rear views of different Pure models and connection points.

Details the rear view of the instrument and connections on the gradient valve.

Explains the information provided on the instrument's type plate for identification.

Details that the scope of delivery depends on the specific purchase order configuration.

Provides detailed technical specifications for various Pure chromatography instrument models.

Specifies the required ambient conditions for optimal and safe instrument operation.

Lists the materials used for different components of the instrument.

Provides notices and instructions for safe transport to prevent breakage and damage.

Guidelines on storing the instrument, including ambient conditions and solvent requirements.

Details the proper procedure for lifting the instrument to prevent injuries and damage.

Checks before installation and requirements for the installation site.

Procedure for using the earthquake fixing point to secure the device against falling.

Guidelines for safely establishing electrical connections, including power supply requirements.

Instructions for connecting solvent bottles to the instrument and safety precautions.

Step-by-step guide for installing the solvent level sensor.

Procedure for assigning specific solvents to solvent lines via the software interface.

Instructions for calibrating the solvent level sensor using the instrument's software.

Guides for installing the exhaust (ELSD) and assembling the waste bottle.

Step-by-step guide for installing the waste level sensor.

Instructions for calibrating the waste level sensor using the instrument's software.

Guides for assembling optional dry air supply and gas connections.

Detailed steps for assembling the optional gas connection tubing and filter.

Instructions for assembling the optional solvent bottle platform, including drain line.

Procedure for assembling the sample loop for prep instruments.

Layout and functionality of the control panel, including menus and value entry.

Details on Conditions, Collection, Gradient, and Run panels for method setup and control.

Panels for selecting solvents, detectors, and configuring slope detection parameters.

Detailed steps for editing methods, including cartridge, column, solvent, and gradient.

Procedures for adding, deleting, and defining solvents used in the instrument.

Procedures for sample injection, cartridge/column handling, and fraction collection setup.

Step-by-step guides for performing flash separations using methods or manually.

Step-by-step guides for performing prep separations using methods or manually.

Methods for identifying fractions and exporting run data to USB or as reports.

Table outlining daily, weekly, and monthly maintenance tasks for optimal instrument performance.

Steps for performing data backup and calibrating the instrument's display.

Detailed steps for cleaning the nebulizer, including materials and sonication.

Method for cleaning check valves by pumping a detergent solution through them.

Procedures for flushing the instrument and column system with solvent.

Instructions on how to clean the solid loader component.

Procedure for purging solvent from an installed cartridge using air.

Addresses common issues like power loss, system shutdowns, and unresponsive touch screens.

Troubleshooting for issues related to RFID tag detection and cartridge recognition.

Solutions for problems like no solvent flow, pump not primed, and inconsistent solvent flow.

Troubleshooting for injection leaks, loader issues, and fraction collection problems.

Addresses low ELSD signals, blocked nebulizers, and poor ELSD peak shape.

Lists common error messages and their possible causes and solutions.

Procedure to reset the fraction collector arm if it fails to home properly.

Guide for replacing the shuttle valve rotor as a maintenance or troubleshooting step.

Steps to safely switch off and disconnect the instrument from the power supply.

Information on responsible disposal of equipment in compliance with local regulations.

Contact information and procedure for returning the instrument to BÜCHI Service Department.

Lists available accessories like rack types and their order numbers.

Catalog of accessories for sample introduction, including solid loaders and loops.

Listing of essential spare parts like cartridge holders, column holders, and valves.

Details on various types of pure glass tubes and their quantities.

Information on available tools and adapter kits, such as Luer lock connection sets.

List of wear parts like air filters, nebulizers, and flow cells requiring periodic replacement.

Specifies the default directory paths for method and run files on the instrument.

Guides on using the Navigator tool for TLC Silica, LC-C18, and LC-Transfer separations.

| Type | Flash Chromatography System |

|---|---|

| Sample Loading | Manual or Automated |

| Detection | UV/Vis |

| Control | Touch screen interface |

| Fraction Collection | Automated |

| Pump Type | Dual piston pump |

| Power Requirements | 100-240 V, 50/60 Hz |