22

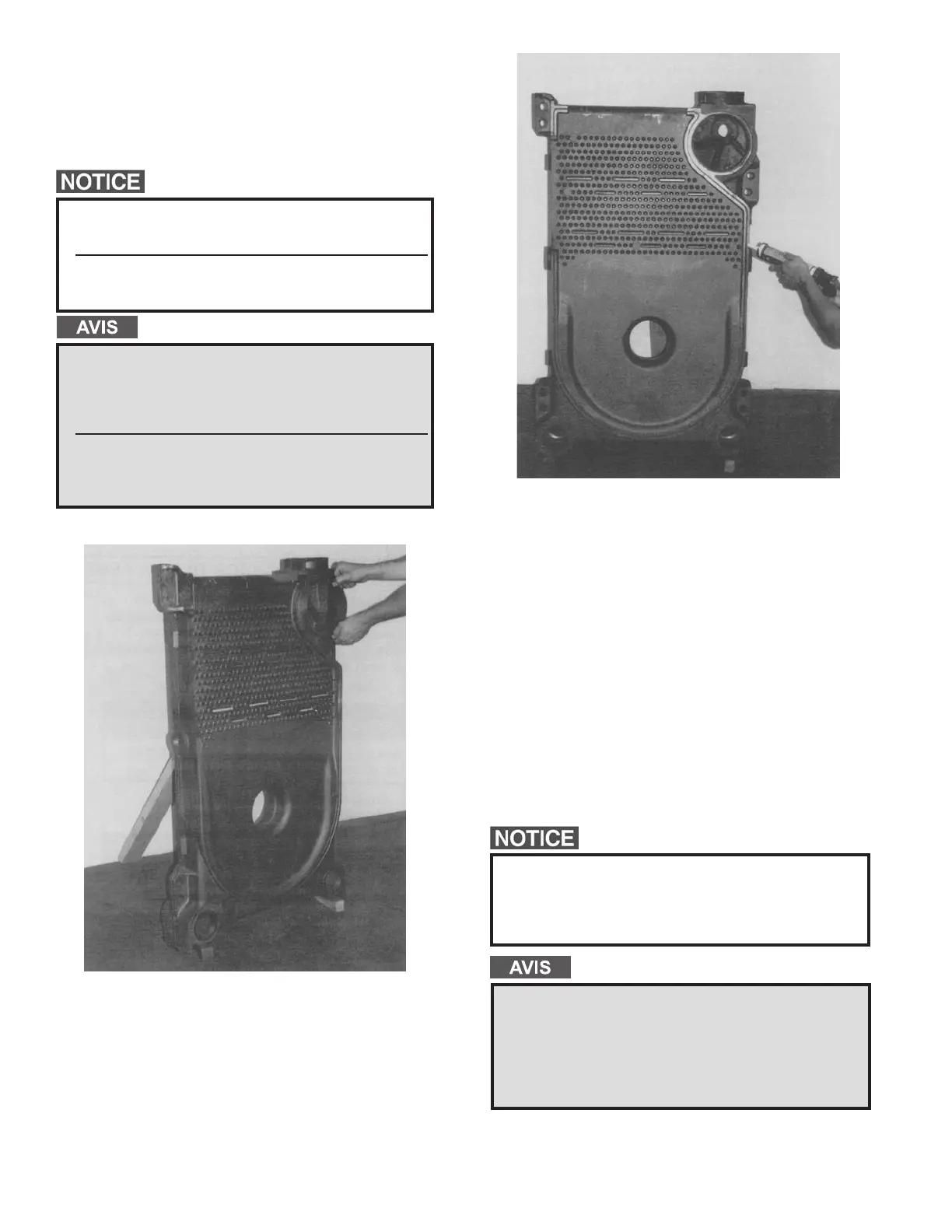

f. Drive nipples squarely into section using

block of wood and hammer, or preferably, an

aluminum head hammer. (Burnham oers a

Polyethylene Block for setting the nipples, part

number 8052601). Place block over entire nipple

edge and hit the wood with the hammer.

Nipples must be driven in evenly and to the proper

depth to assure tight joints. Most nipple leaks are

caused by tilted or cocked nipples.

DO NOT use steel/iron head hammer to drive

nipples without using a wood block. Nipple

damage may result.

Les mamelons doivent être enfoncés

uniformément et à la bonne profondeur pour

assurer des joints serrés. La plupart des fuites

de mamelons sont causées par des mamelons

inclinés ou armés.

NE PAS utiliser de marteau à tête en acier / fer

pour enfoncer les mamelons sans utiliser de cale

en bois. Des dommages au mamelon peuvent en

résulter.

Figure 6: Setting of Nipples

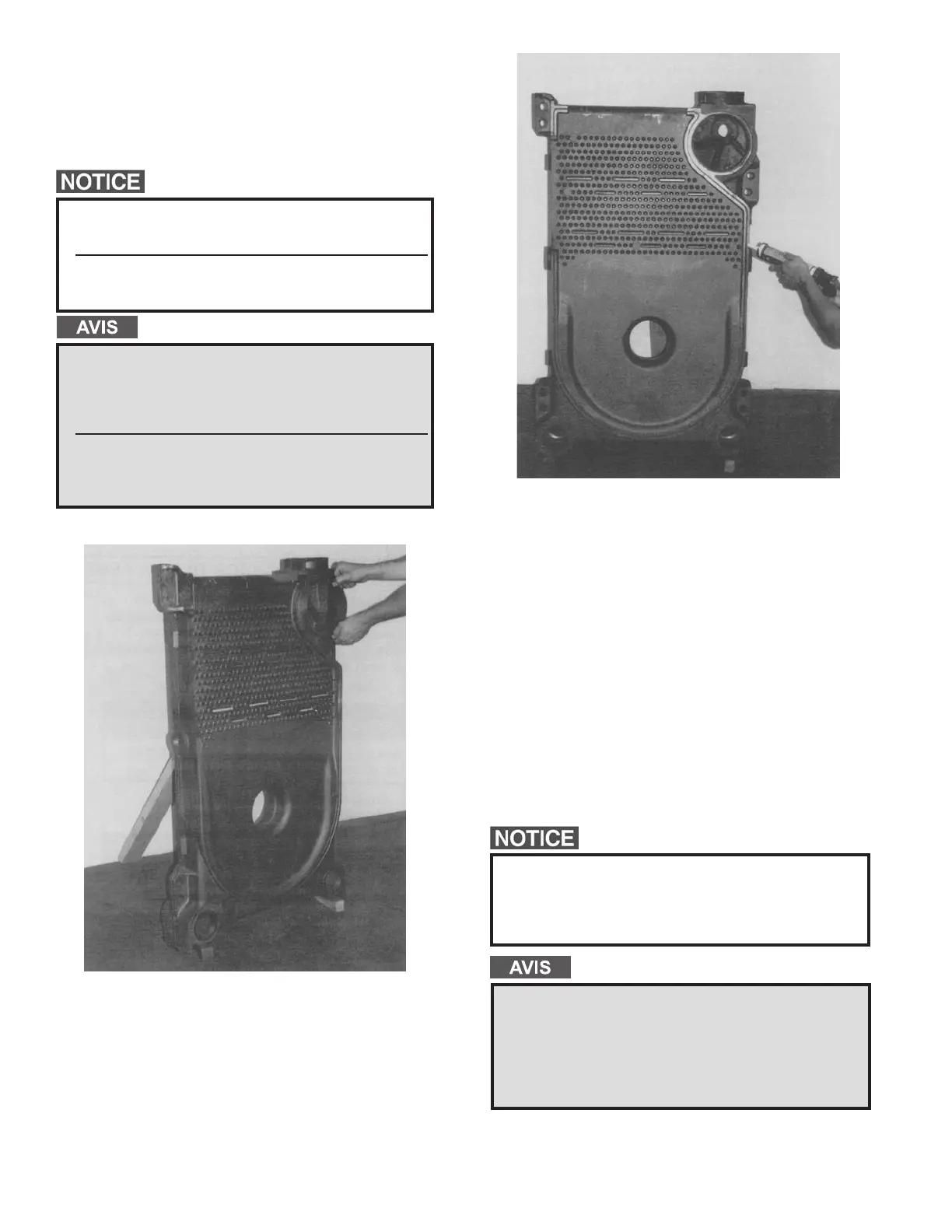

h. Remove a 96″ length of berglass rope from

the assembly carton. Starting with the area

around the upper 7″ nipple port, rmly press

the rope into the groove, so that the adhesive

holds it in place. (If more than 25 minutes have

passed since the adhesive was applied, it may

be necessary to reapply.) Continue to ax the

rope to the groove in this fashion around the

perimeter of the section. Make sure that the rope

does not droop or hang outside of the groove.

When the end of the groove is reached, cut o

the excess rope. Push the length of excess rope

into the groove at the top corner of the section

face (opposite of the 7″ nipple port.) Cut o and

discard any remaining rope after groove is lled.

See Figure 7.

The sections must be assembled according to the

arrangement shown to ensure proper operation, proper

assembly of canopy, jacket and alignment of piping and

tankless heaters with jacket knockouts. Start with the

back section and work towards the front.

Les sections doivent être assemblées selon

la disposition illustrée pour assurer un bon

fonctionnement, un assemblage adéquat de l’auvent,

de la chemise et l’alignement de la tuyauterie et des

appareils de chauage sans réservoir avec des

débouchures de chemise. Commencez par la partie

arrière et travaillez vers l’avant.

Figure 7: Axing the Fiberglass Rope

g. A special nipple setting gauge is provided for the

nipples. Gauge nipple at 90° angles to insure that

it is driven to the proper depth into the nipple

opening (nipple port). Cut-out in gauge must rest

on nipple, with legs of gauge touching nished

face of section, when nipple is properly driven.

See Figure 6.

Loading...

Loading...