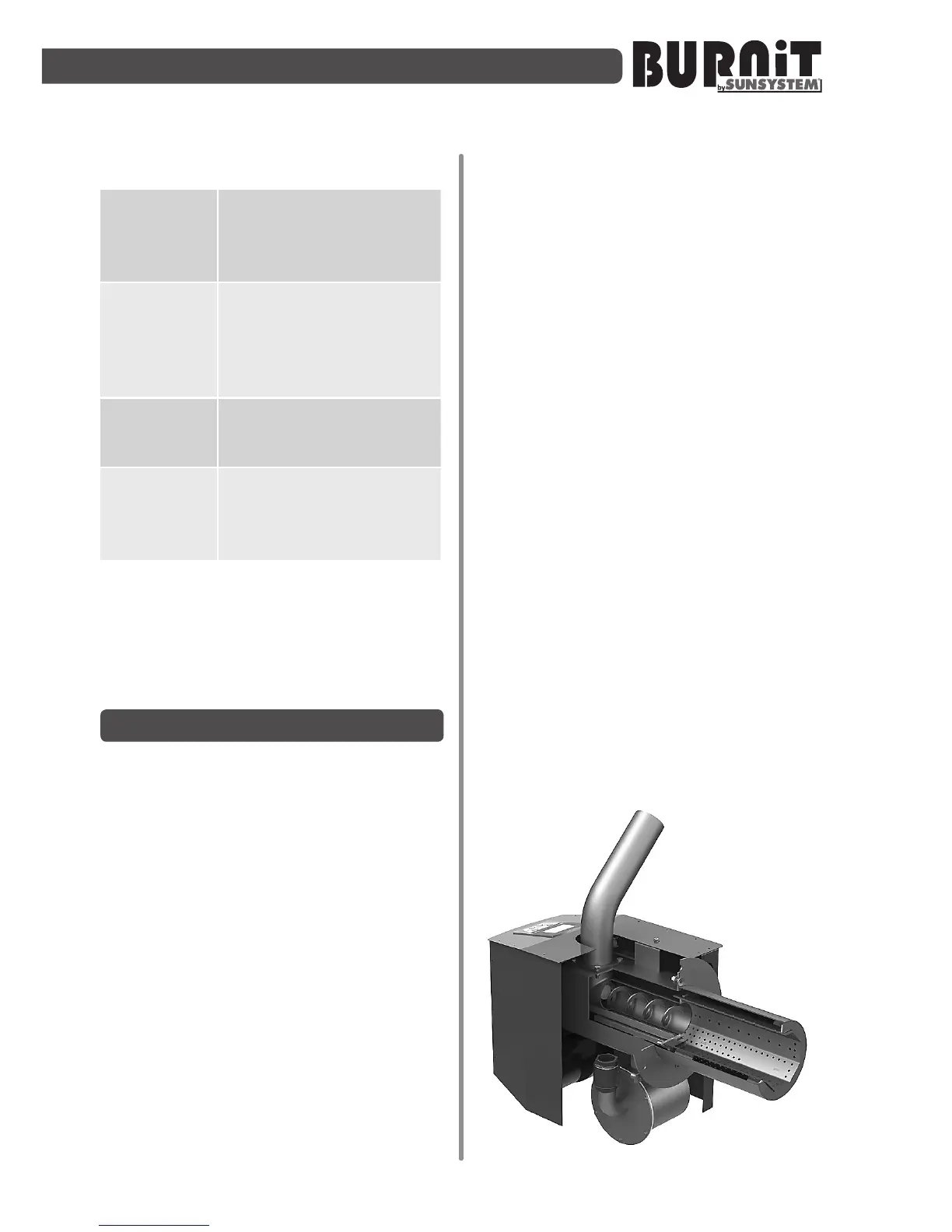

Table 1. Combusbility of

PPPconstrucon materials

ClassА -

non-

combusble

Stone, bricks, ceramic

tiles, baked clay,

solutions, plaster free of

organic additives.

Class B -

hard

combusble

Gypsum board panels,

basalt fiber needled

felt, fiberglass board,

AKUMIN, Izomin, Rajolit,

Lignos, Velox, Heraklit.

ClassС1/С2-

Medium

combusble

Wood beech, oak

Wood softwood, layered

wood

Class C3 -

easy

combusble

Asphalt, cardboard,

cellulose, tar, fiberboard,

cork, polyurethane,

polyethylene.

For general safety consideraons, we

recommend that the boiler be placed

on a foundaon with height of 100 mm

made of class A material, see table 1.

2. PRODUCT DESCRIPTION

The BURNiT Pell pellet burner for hot

water boilers is designed to burn only

and exclusively wood pellets and it is

intended to heat up heang boilers. The

built-in control unit, automac cleaning

system and internal pellet auger ensure

the automated operaon of the burner

and opmal burning of the fuel.

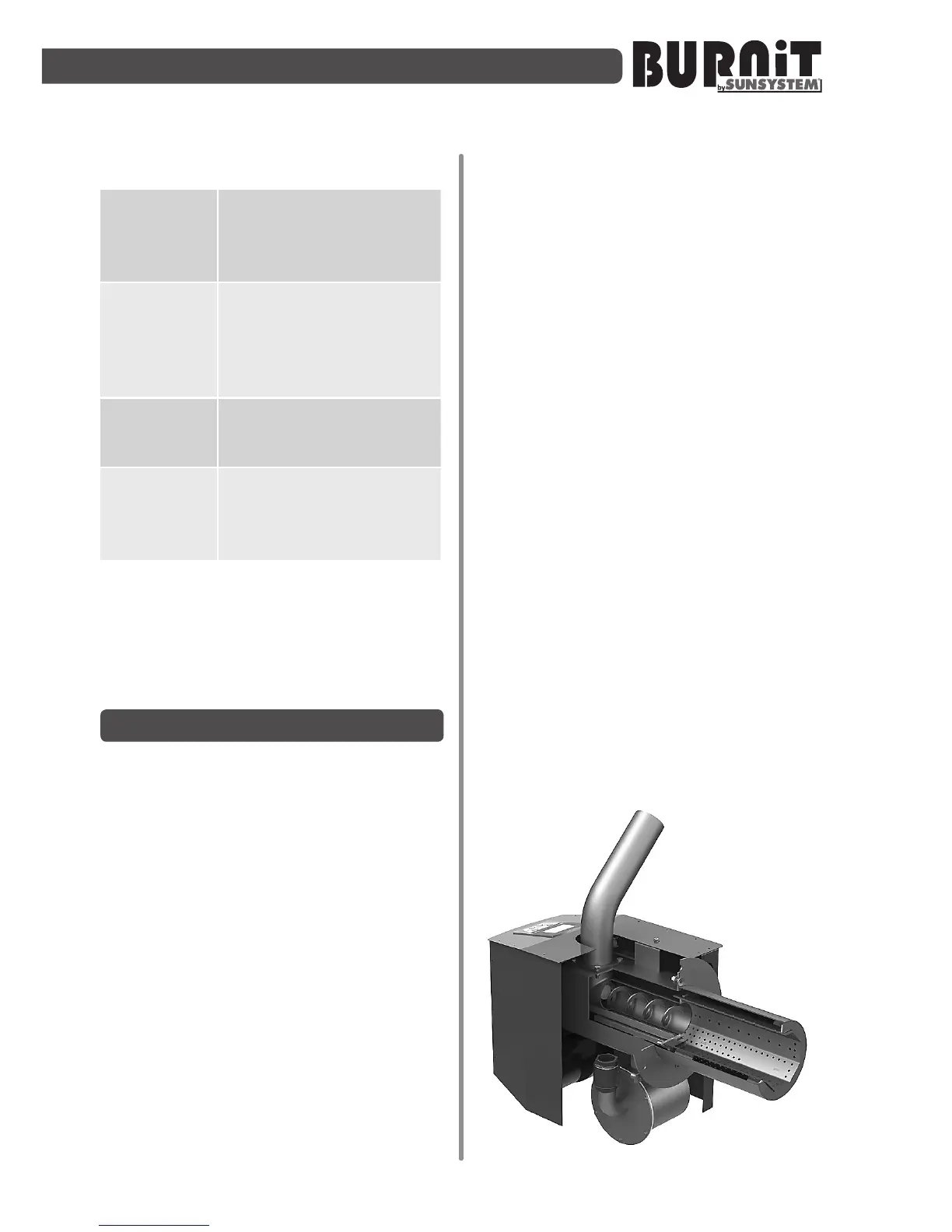

2.1.Design.

The burner is made of high-quality

stainless steel able to withstand

temperatures of up to 1150°С. The

burner must be installed on a heang

boiler.

The burner consists of two parts:

combuson chamber tube and

external tube with sheet metal mantle.

Longitudinally, under the housing, there

are blow chamber, fuel ignion heater,

fan and power supply. On the upper part

of the burner there is a feeder chute

to which the pellet auger is aached.

The housing of the burner has been

designed to meet all regulatory safety

requirements (no sharp or protruding

elements) with operang temperature

not exceeding 50 °C.

The combuson chamber consists of two

tubes:

Ember resistant steel tube inside the

burner with holes for air intake along

its enre length, opening for the hot air

from the fuel ignion heater, opening for

photosensor.

Outer stainless steel tube. Between the

two tubes there is a gap which provides

for free circulaon of the air necessary

both for cooling and oxygen supply into

the combuson chamber.

The feeder chute allows 360° rotaon

for its best convenient posioning

when connecng the pellet auger to the

hopper.

Diagram 2. Pellet burner Pell design

Loading...

Loading...