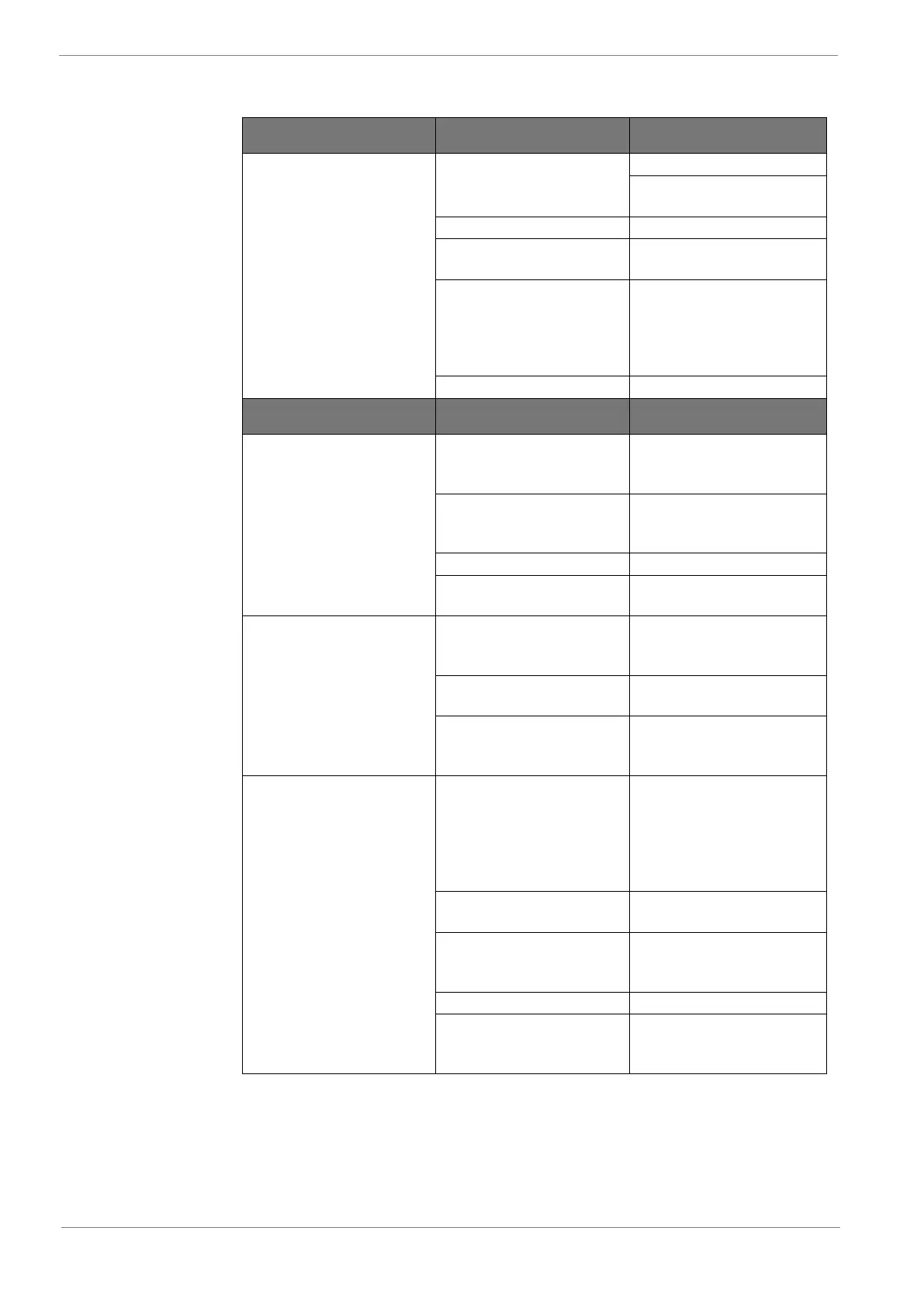

9 | Troubleshooting

/ 44

0870S03226_VRD 2072-3108_-

9.2 Failure table and measures

Problem Possible cause Remedy

The vacuum pump does

not start up.

The required voltage is

not pending at the mo-

tor.

Check the power supply.

Switch on the main

switch.

The motor is defective. Replace the motor.

The coupling (CPL,

fig. 17) is defective.

Replace the coupling

(CPL, fig. 17).

Motor protection switch

has triggered

Turn the motor protec-

tion switch (101Q1,

101Q2, 101Q3) to po-

sition “0” and then to

position “1”.

Fuse has triggered.

Check fuse (100F1).

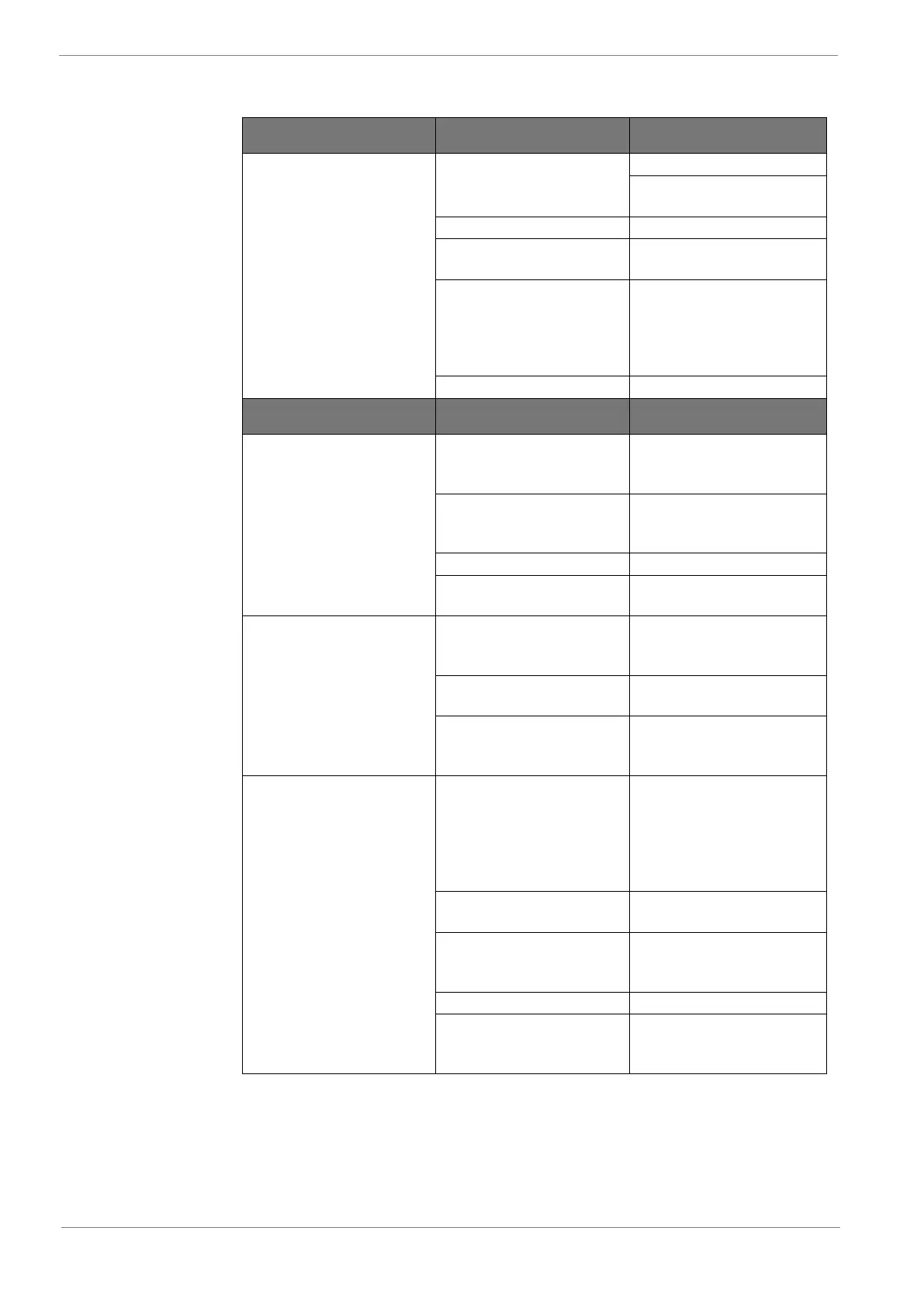

Problem Possible cause Remedy

The required pressure

cannot be built up on the

intake connection.

The intake screen (IS,

fig. 17) is partially

clogged

Clean the intake screen

(IS, fig. 17).

Inner components are

worn or damaged

Have the vacuum pump

repaired

(Busch Service)

The oil level is too low

Top up oil.

Leak in piping system

age.

High noise development

during operation of the

vacuum pump

The bearings are defec-

tive.

Have the vacuum pump

repaired (Busch Ser-

vice).

The coupling (CPL,

fig. 17) is worn.

Replace the coupling

(CPL, fig. 17).

The sliders are stuck.

Have the vacuum pump

repaired

(Busch Service).

High heat development

during operation of the

vacuum pump

The cooling is insuffi-

cient.

Clean the vacuum

pump from dust and

contamination.

• Check the cooling water

inlet (version with oil-

water heat exchanger)

The ambiance tempera-

ture is too high.

Observe admissible am-

biance temperature.

The fan does not run or

turns in the wrong direc-

tion.

Check electrical connec-

tion.

The oil level is too low. Top up oil.

The exhaust filters (EF,

fig. 2 and 17) are partial-

ly clogged.

Replace the exhaust fil-

ters (EF, fig. 2 and 17).

Loading...

Loading...