11 | Troubleshooting

28 / 36 0870231979_WT0100-0730CP_CV_-0001_IM_en

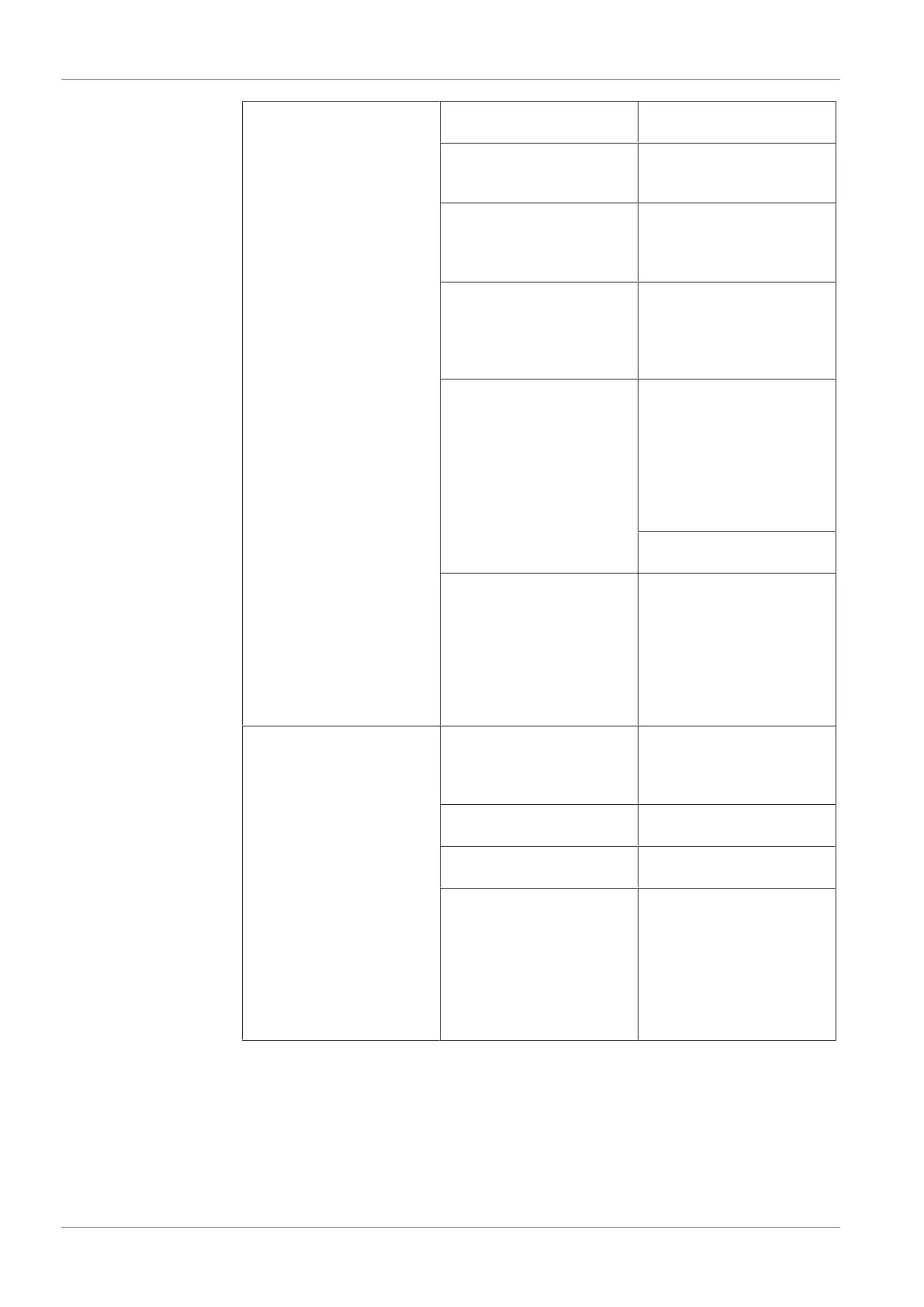

Abnormal heat develop-

ment.

STOP THE MACHINE IM-

MEDIATELY !!

Abnormal increase in ex-

haust temperature.

• See causes marked with.

Too low rpm on blower

(and/or motor with fre-

quency regulation)

• Check the minimum al-

lowed rpm. And correct

the setting.

Too high oil level. • The oil level must be at

the top of the level indic-

ator when the blower is

not running.

Under pressure in the ma-

chine room.

• Check the ventilation sys-

tem and correct the vent-

ilation amount or air lock

sizes so there is not under

pressure in the room.

To high differential pressure. • Check, clean and replace

the inlet filter. Check

pipes and process system

on both sides of the

blower for blockages, ob-

structions, both mechan-

ical and control system re-

lated.

• and begin repairs of the

blower.

Abnormal wear on the lobes

after strain from solid media

(e.g. dust from operation

without inlet filter, CIP

cleaning of the blower dur-

ing operation with aggress-

ive cleaning fluids or stress

from aggressive gases).

• Install inlet filter to pro-

tect the blower

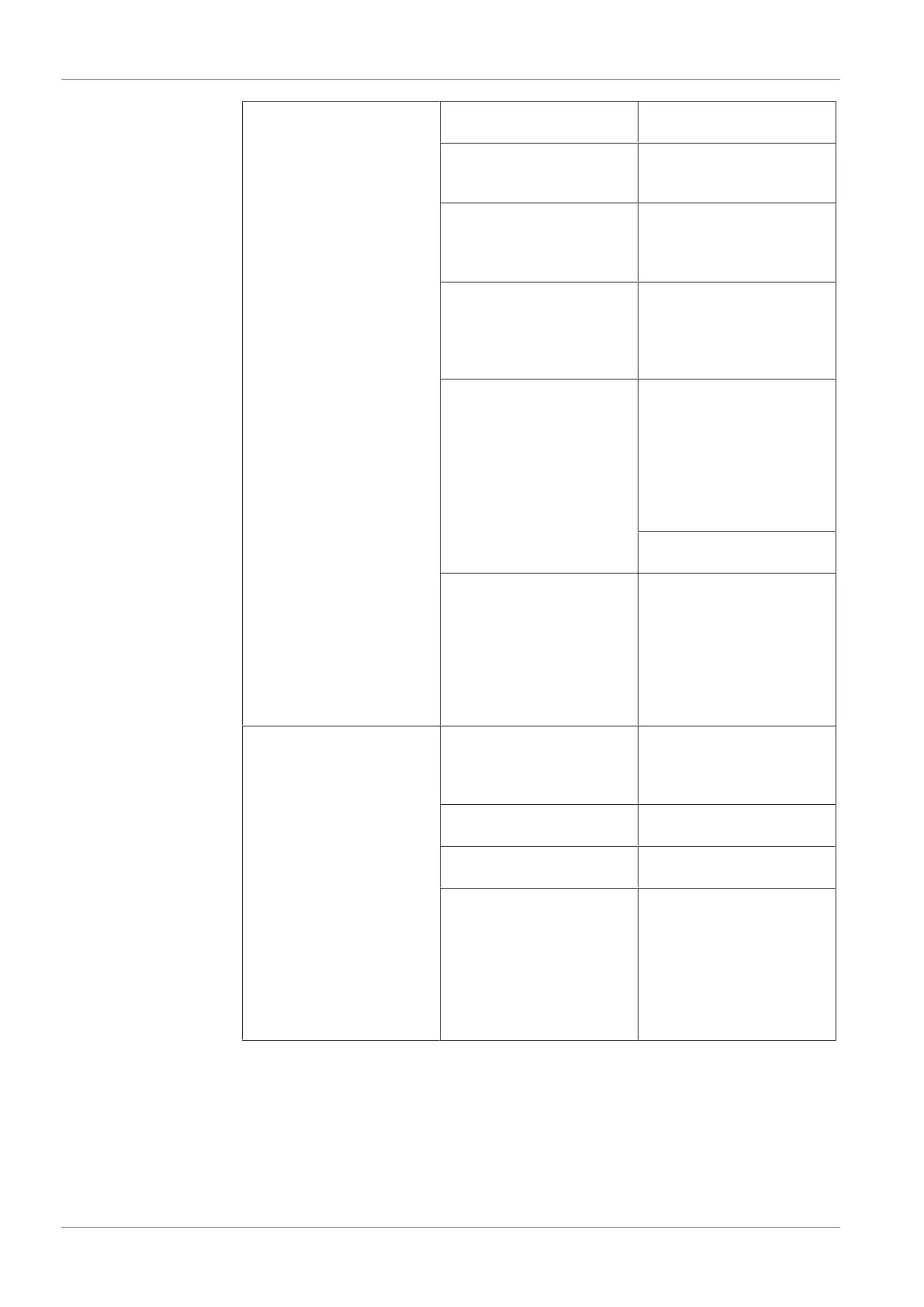

Oil leakage. Too high oil level (above

max on level indicator in

cabinet)

• The oil level must be

between MIN and MAX

on level indicator on cab-

inet front.

Leaking or damaged shaft

seals.

• Begin repair in workshop.

Blower has been tilted or is

not mounted horizontally.

• Place on horizontal

foundation.

Too high differential pres-

sure.

• Check, clean and replace

the inlet filter. Check

pipes and process system

on both sides of the

pump for blockages, ob-

structions, both mechan-

ical and control system

based.

Loading...

Loading...