20

EN

Following any overow situation reduce the water

level in the cabinet by manually removing the

excess water and initiate a manual regeneration as

described on page 19.

NB: Check the water level weekly and following

any unplanned event, e.g. power failure.

4.3 Setting the hardness of blended water

To test the water hardness, allow the nearest cold

water tap to run for a while and check the hardness

of the blended water using the hardness test kit.

Adjust with the blending valve V until the desired

value is reached.

5. Maintenance

5.1 Maintenance work

The operator must regularly perform the

following checks to guarantee that the unit

functions properly.

Check the salt and rell after use.

Check the water hardness: The hardness of

drinking water and the set blended water hardness

must be checked 2x annually and the hardness

of the blended water must be corrected when

required.

Check for leaks, visual inspection: Check

connection lines and connections for leaks. Check

for dirt in the regenerative storage area and brine

cavity every two months and clean and ush with

clear water if necessary.

The intervals between checks are recommended

minimums and must be adjusted according to site

conditions.

5.2 Operator responsibilities

All technical equipment requires regular servicing in

order to guarantee optimal functionality.

Keep yourself up to date with regard to the quality

and pressure ratio of the water which is to be

treated. If the water quality changes, the settings

may need to be changed. Consult a specialist if

necessary.

Regular checks by the operator are required for

the warranty and proper functioning of the unit.

The water softener must be inspected regularly in

accordance with the conditions of operation and

use.

Operator check intervals:

After use: Rell regeneration salt

2x Annually: Check pressure

2x Annually: Check water quality

1x Annually: Clean brine container

If you are using a battery power supply:

After use / weekly: Check for low battery symbol

If illuminated – change battery.

5.3 Maintenance & wearing parts

Wearing parts must also be replaced within the

prescribed maintenance intervals in order to

guarantee functionality and full the warranty

conditions. The water softener should be serviced

once a year.

Contact BWT Customer Service when your

softener displays the service symbol on the display

to arrange your service.

Wearing parts may only be replaced by qualied

personnel (contact BWT customer service team).

The BWT customer service team offer a range of

maintenance and service options for your softener.

Cleaning information: Do not use alcohol or alcohol

based cleaning agents, otherwise the plastic

surfaces of the device will be damaged.

5.4 Disposal

At the end of product life please contact BWT

Customer Services to arrange a new replacement

for your softener Disposal of your softener and

any electrical parts should only be carried out at

authorised WEEE recycling centres.

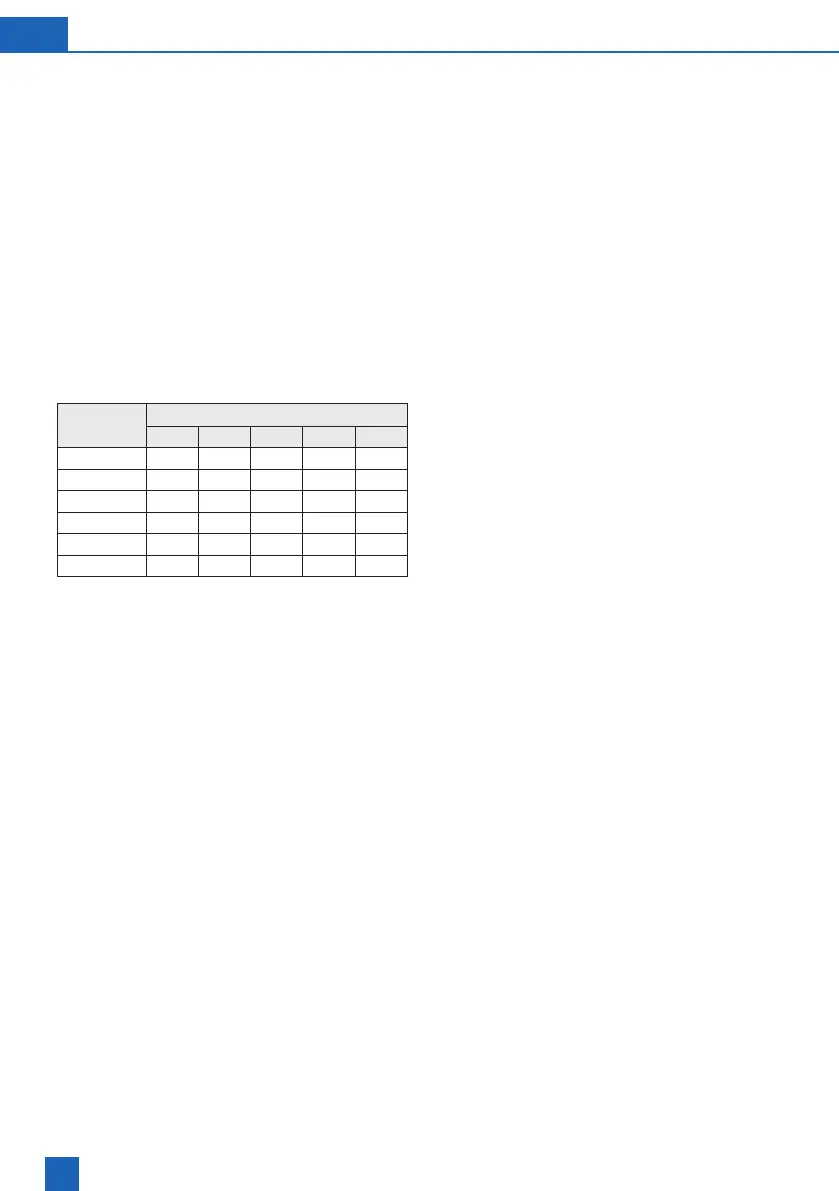

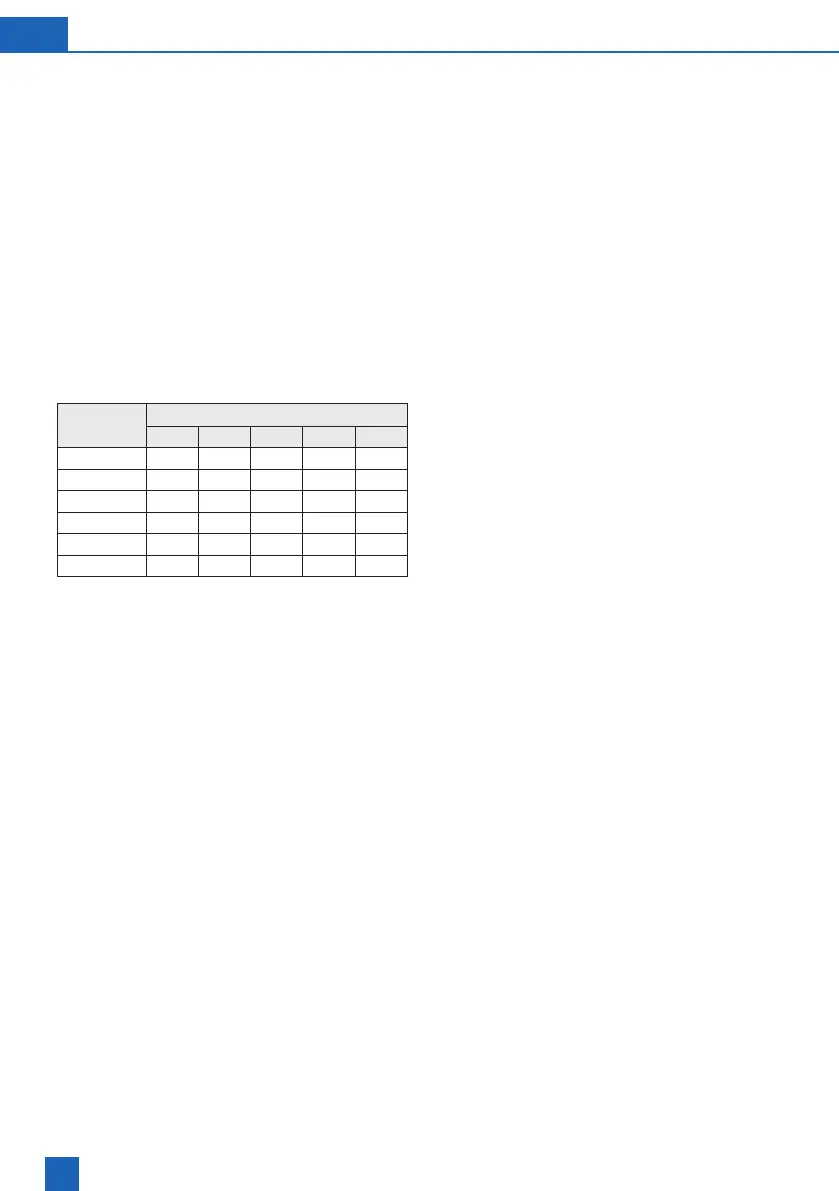

Hardness

in ppm

No. of people

02 03 04 05 06

150 8 7 6 5 4

200 7 6 5 4 3

250 6 5 4 3 2

300 5 4 3 2 1

350 4 3 2 1 1

400 3 2 1 1 1

= Days between regeneration (Guide Only)

Loading...

Loading...