ENGINEERING MANUAL • Approved Document No. DFU5010000 Rev 4 • Page 11 of 48

CAST XFP 16 ZONE ANALOGUE ADDRESSABLE FIRE ALARM PANEL

GENERAL

FIRE

ZONE 1

ZONE 2

ZONE 3

ZONE 4

ZONE 5

ZONE 6

ZONE 7

ZONE 8

ZONE 9

ZONE 10

ZONE 11

ZONE12

ZONE 13

ZONE 14

ZONE 15

ZONE 16

D45

SUPPLY

PRESENT

TEST

ACCESSED

GENERAL

DISABLEMENT

PHASED

EVACUATION

GENERAL

FAULT

PSU

FAULT

SYSTEM

FAULT

SOUNDER

STATUS

DELAYS

RUNNING

Auxilliary

+24V I/P1 I/P2 0v

Relay 1

NC C NO

Relay 2

NC C NO

Relay 3

NC C NO

Fault

NC C NO

Sounder Circuits

+ 1 -

+ 2 -

Earth Fault Detect

Addressable Loop

+ A -

+ B -

REMOVING THIS CIRCUIT

BOARD EXPOSES HAZARDOUS

VOLTAGES - PLEASE REFER TO

INSTALLATION INSTRUCTIONS

WARNING

SENSITIVE TO STATIC

ELECTRICITY - OBSERVE

PRECAUTIONS BEFORE

HANDLING

CAUTION - RISK OF EXPLOSION IF

INCORRECT TYPE OF BATTERIES FITTED.

DISPOSE OF USED BATTERIES ACCORDING

TO THE MANUFACTURERS INSTRUCTIONS.

FOR OPERATIONAL DETAILS PLEASE

CONSULT THE MAINTENANCE MANUAL

Mute

Beeper

A Short

B Short

4

3

4

3

4

3

4

3

Fig.8 : Relay output detail

+–+–

+

I

+

+

I

–

+

–

Location of small

sized batteries

typically 1.2Ah

Location of medium

sized batteries

typically 2.1Ah

+

+

–

–

+

Take care to arrange

batteries so terminals

do not touch

Location of large

sized batteries

typically 3.0Ah

Connection of leads

to Power Supply PCB

Run the battery leads

(supplied) through slits

in the plastic ribs

R E D

BLACK

Tie wraps

Link wire

12V 12V 12V 12V 12V 12V

Power Supply

PCB

BAT1

BF232

(USB-to-RS232 Convertor)

Control Panel

Main Control

PCB

SAF7070000

(Molex-to-RS232 Lead)

To USB

PC/Laptop

To PL5

Programming Connector

RS232 Connections

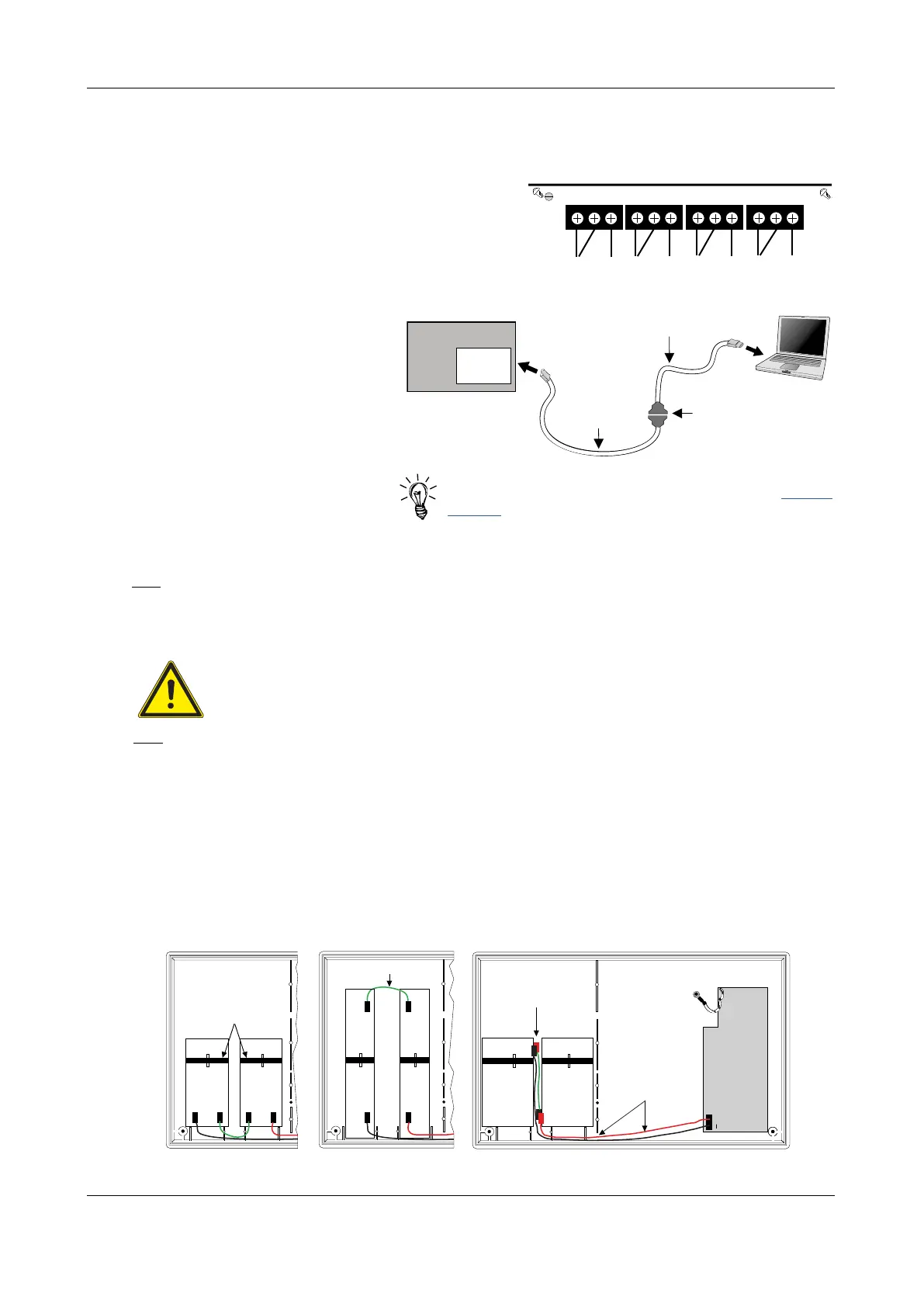

Fig.9 : Connecting a PC to the panel’s RS232 connector

Hint! Application Note 0001.0 (Setting up a Serial Comm

Port on a PC) is available in the Support Hub @ www.c-

tec.com to assist with setting up panel to PC comms.

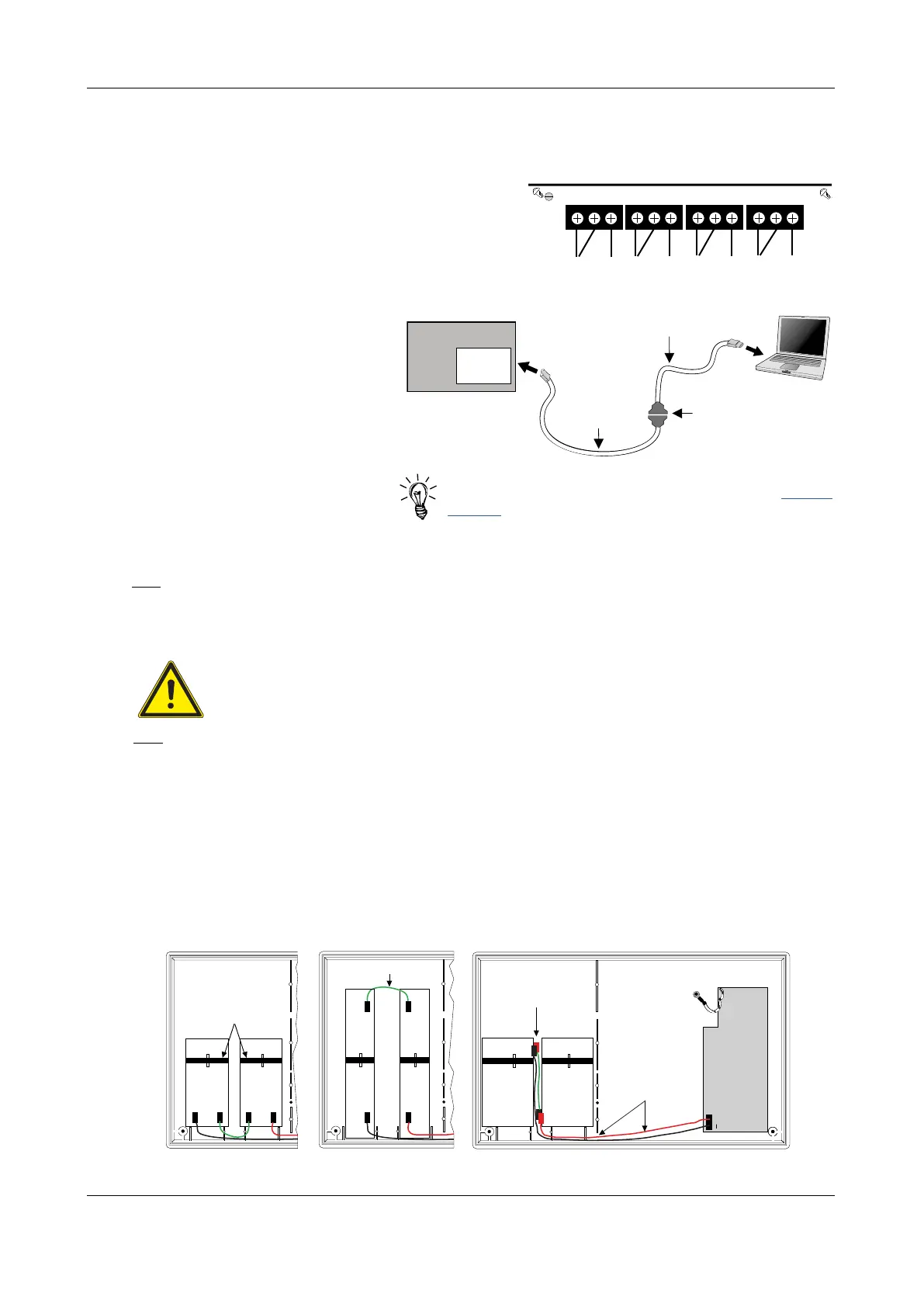

Installing the standby battery supply

There is a risk of explosion if incorrect battery types or sizes are used. Always replace both

batteries and always dispose of used batteries in accordance with the battery manufacturers

instructions and local regulations. Batteries are heavy and can produce dangerously high

currents if shorted. Take care when handling and routing battery leads to avoid damage.

Two new, good quality and fully charged 12V valve regulated lead acid (VRLA) batteries are required

as the emergency stand-by power supply for the panel. The batteries should be connected in series and

located in the panel’s enclosure, as shown in Fig.10 below. Battery leads, link wire and cable ties are

provided in the panel’s accessory pack. Run the battery leads through the slits in the panel’s lower plastic

ribs and secure the batteries into position using the cable ties as shown.

The panel’s sophisticated battery monitoring unit protects the batteries against deep discharge by

activating a cut off circuit when the stand-by supply voltage reaches 21V approx. If batteries are not

fitted, are discharged or in poor condition, a PSU fault will show at the panel.

The capacity of the batteries used will depend upon the required stand-by time. To calculate the

batteries required for any given stand-by period, refer to the battery calculation guide on page 46.

Fig.10 : Battery location and connection details

Aux. 24V output

One fused 24Vd.c. output, rated at 100mA, is provided and can be used for supplying power to ancillary

fire alarm equipment.

Remote PC connection

A four-way RS232 molex connector

(PL5) is provided on the Main

Control PCB for the connection of

a Windows based PC / laptop. The

ONLY way to program this panel is

to use the panel’s PC programming

tools (Part No. XFP507).

The SAF7070000 lead supplied with

the tools should be used to connect

the panel and PC shown in Fig.9 right.

Note: A USB to RS232 connector is

also available (Pt. No. SAF8080000).

Relay 1 : Switches when any zone goes into fire, switches back when the panel is silenced.

Relay 2 : Switches when any zone goes into fire, switches back when the panel is reset.

Relay 3 : Has no default operation.

It is recommended that customers wire to the

normally closed (N/C) terminals on the fault relay,

as this is standard industry practice.

Fig.8 (right) shows how the outputs work.

Loading...

Loading...