10 10

2 Replacing Assembly Units

2.4 Replacing the Slipping Clutches

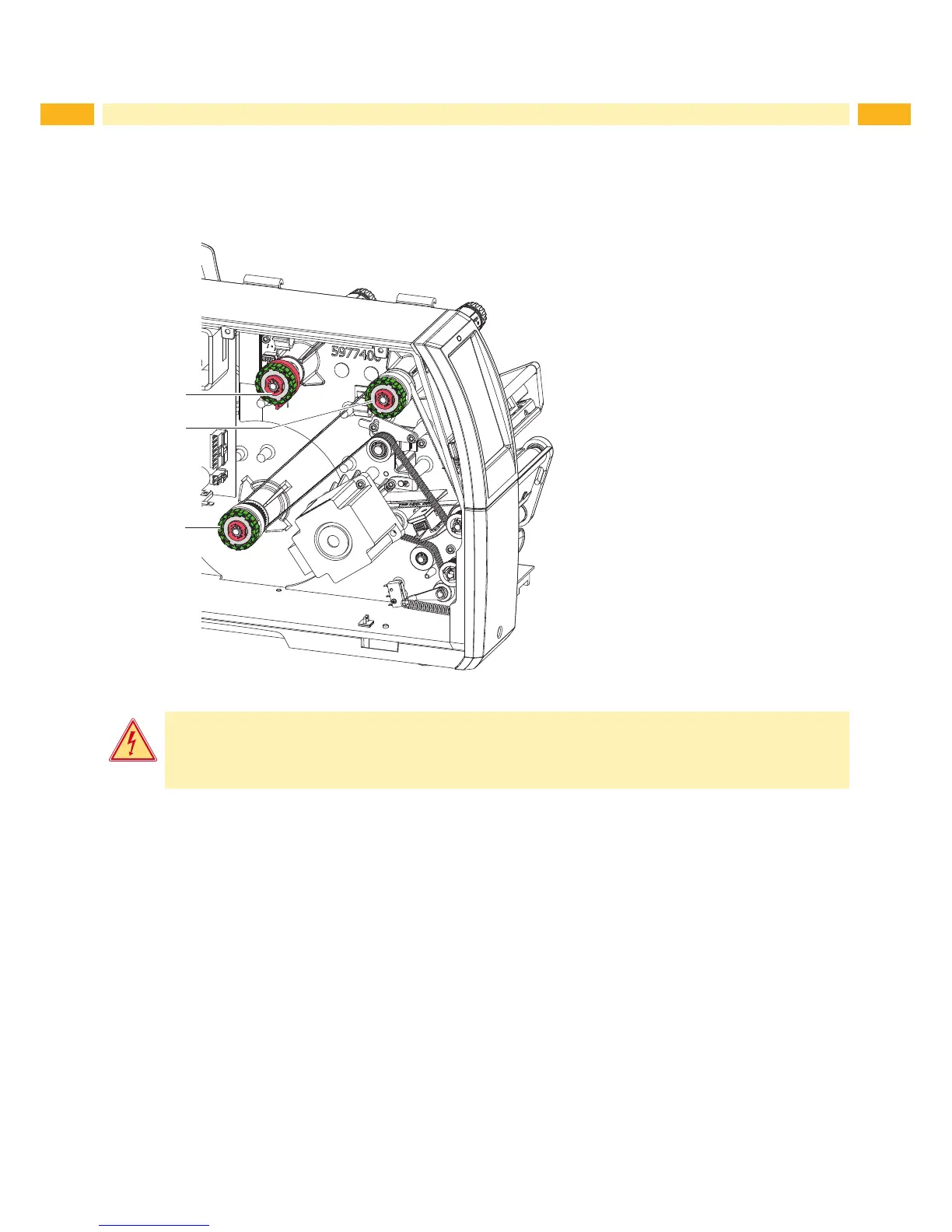

The rewinder for the transfer ribbon and the internal rewinder are coupled with slipping clutches to the main drive.

The supply hub of the transfer ribbon is braked with a slipping clutch during printing.

Replace a slipping clutch when the set value of the torque cannot be set. 3.1 on page 16. Removal and instal-

lation of the slipping clutch is also required for replacement of a winder.

2

1

3

1 Ribbon supply hub: brake

2 Ribbon take up hub: coupling

3 Internal rewinder: coupling

Fig. 4 Slipping clutches

Danger!

Risk of death via electric shock!

Before opening the housing cover, disconnect the device from the mains supply and wait at lease one

minute until the power supply unit has discharged.

Loading...

Loading...