Pag. 9 - Manual code: 119AV31 ver. 2.0 09/2010 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

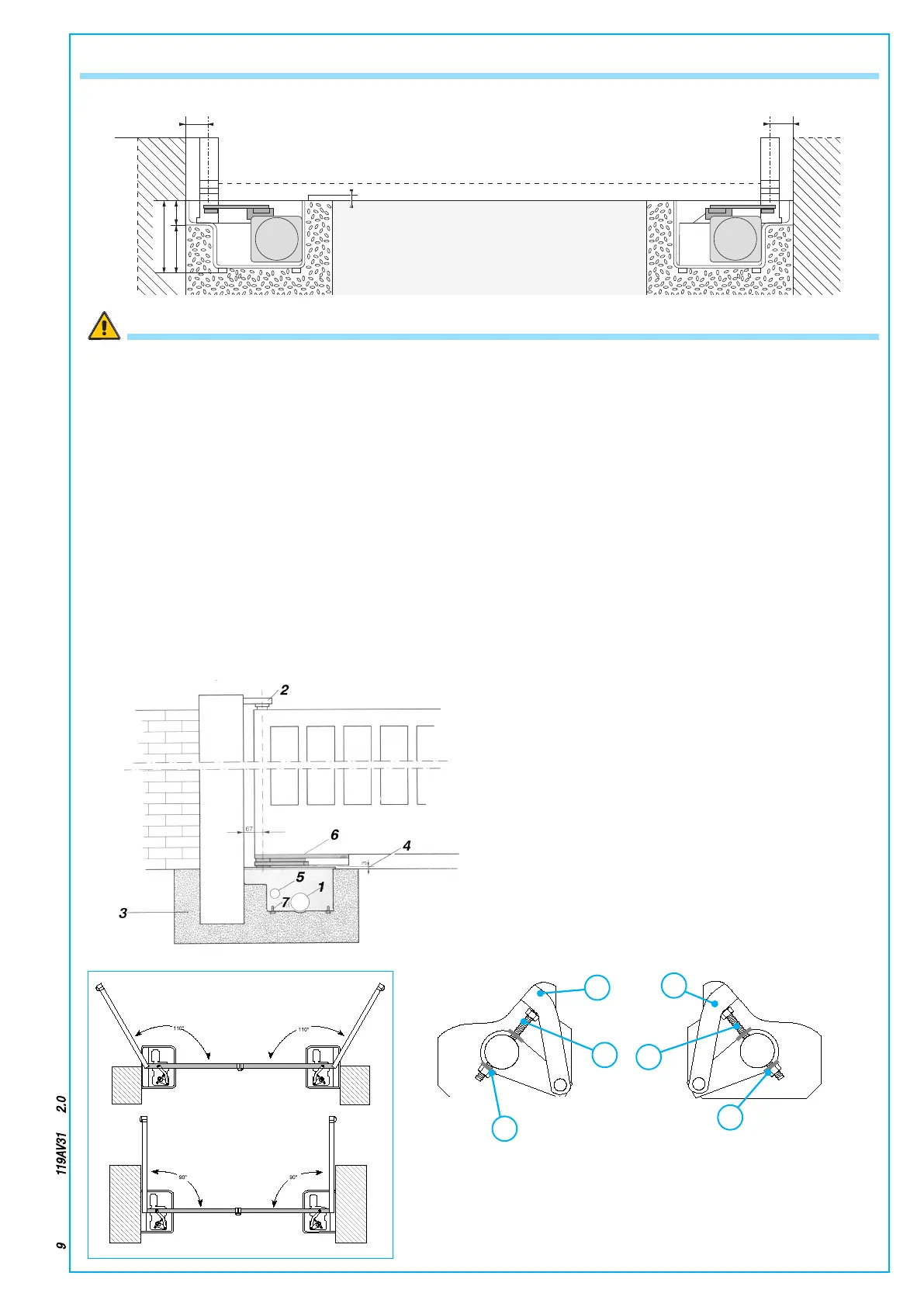

5.5 Assembly diagram

Fig.3

2.64” in

2.6” in

6.3” in

4” in

2.4” in

.12” in

5.6 Installing the unit

- Check the eciency of both moving and non-moving parts on the structure that will be supporting the operator.

- Determine, depending on the type of supporting structure and desired opening, the exact position of the motor assembly

by following the standard applications shown.

- Set up a closing end stop and an opening end stop (g. 4, p. 5)

- Dig, depending on the size of the assembly, a foundation pit in the chosen spot (Fig. 3)

- Prepare a drainage system in the foundation, to drain away any water leaks which may cause oxidation (g 3 – part.1)

- The foundation box makes for quick and easy setting up of the assembly. Place it inside the pit with the pin aligned to

the upper hinge (Fig. 3 – part. 2), sink it into the cement (Fig. 3 – part. 3) making sure it is perfectly levelled and that the

upper edge is 1 inch above ground level (Fig. 3 part. 4)

- Plan for the route of the electrical cables according to the command and safety instructions using the apposite hole on

the box (Fig. 3 – part. 5)

- Grease the rotation pins of the foundation box and the gate attachment lever; the hinge and pin lever must be aligned

- Position the gate leaf between the upper hinge and the pin lever; the hinge and pin lever must be aligned

- Secure the pin lever to the gate leaf, by welding spots from 1 to 1.5 inches apart along the contact surface.

Avoid any welding near the threaded screws (Fig. 3 – Part. 6).

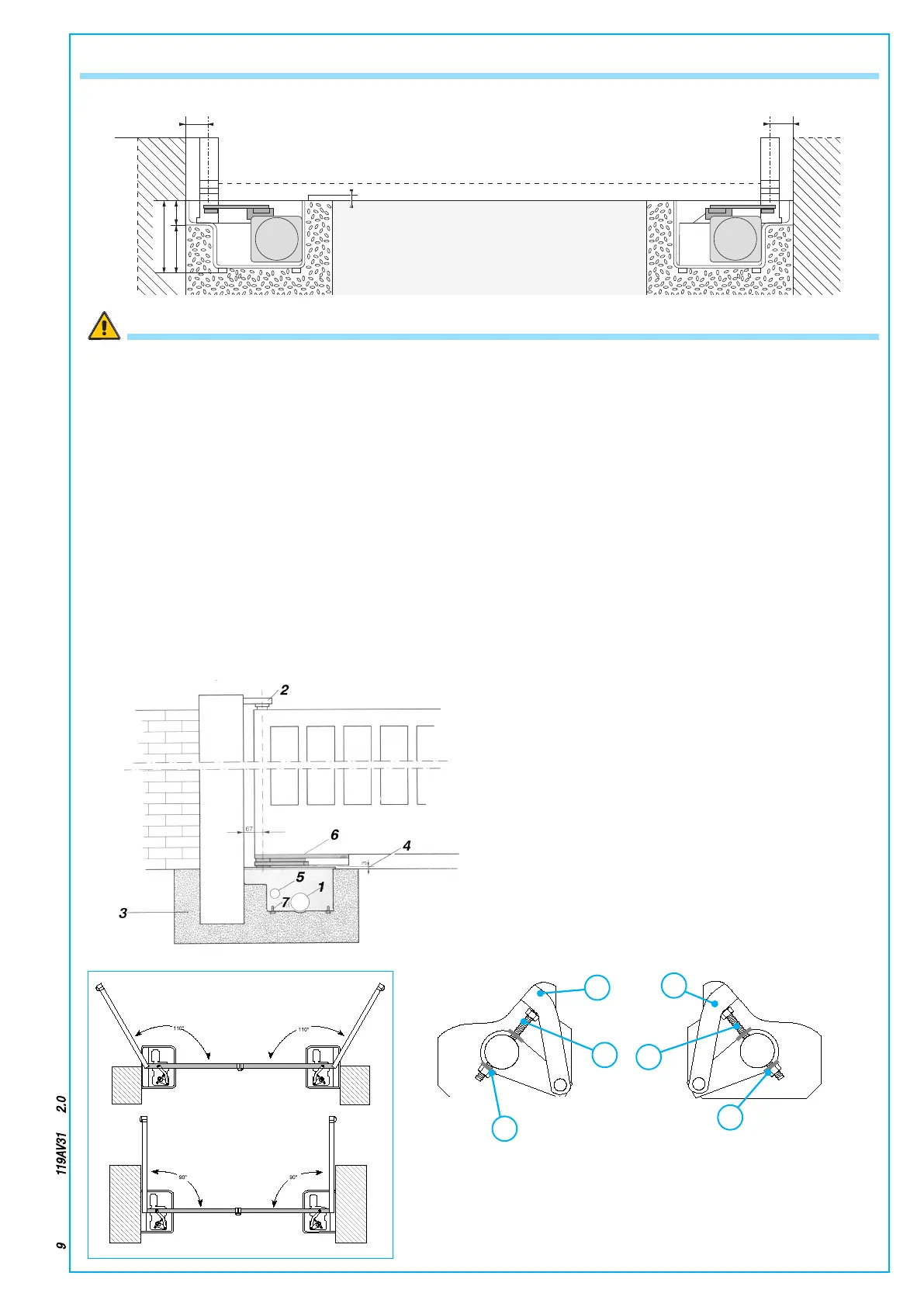

Fig.2

- Screw the M10 x 100 (A) and the M10 (B) bolt onto the

gearmotor arm as shown in g. 4-1 (left HAND installation)

and g. 4-2 (right HAND installation)

- Ax the gearmotor to the foundation box using the threaded

pins and securing it using the provided bolts and washers

- Insert the (C ) transmission lever between the motor arm

and the box lever and electronically shut the gate against

the closing end stop. Adjust screw (A) until it touches the (C)

transmission lever.

- When testing, adjust the screw so as to allow proper closing

pressure of the gate leaf and allow its re-hooking during the

mechanism’s release procedure.

- Once adjustment is complete, secure the (B) nut.

Fig.4

RT

LF

Fig.4-1

Fig.4-2

A

B

C

C

B

A

LF

RT

Loading...

Loading...