48

MF 400 – 600

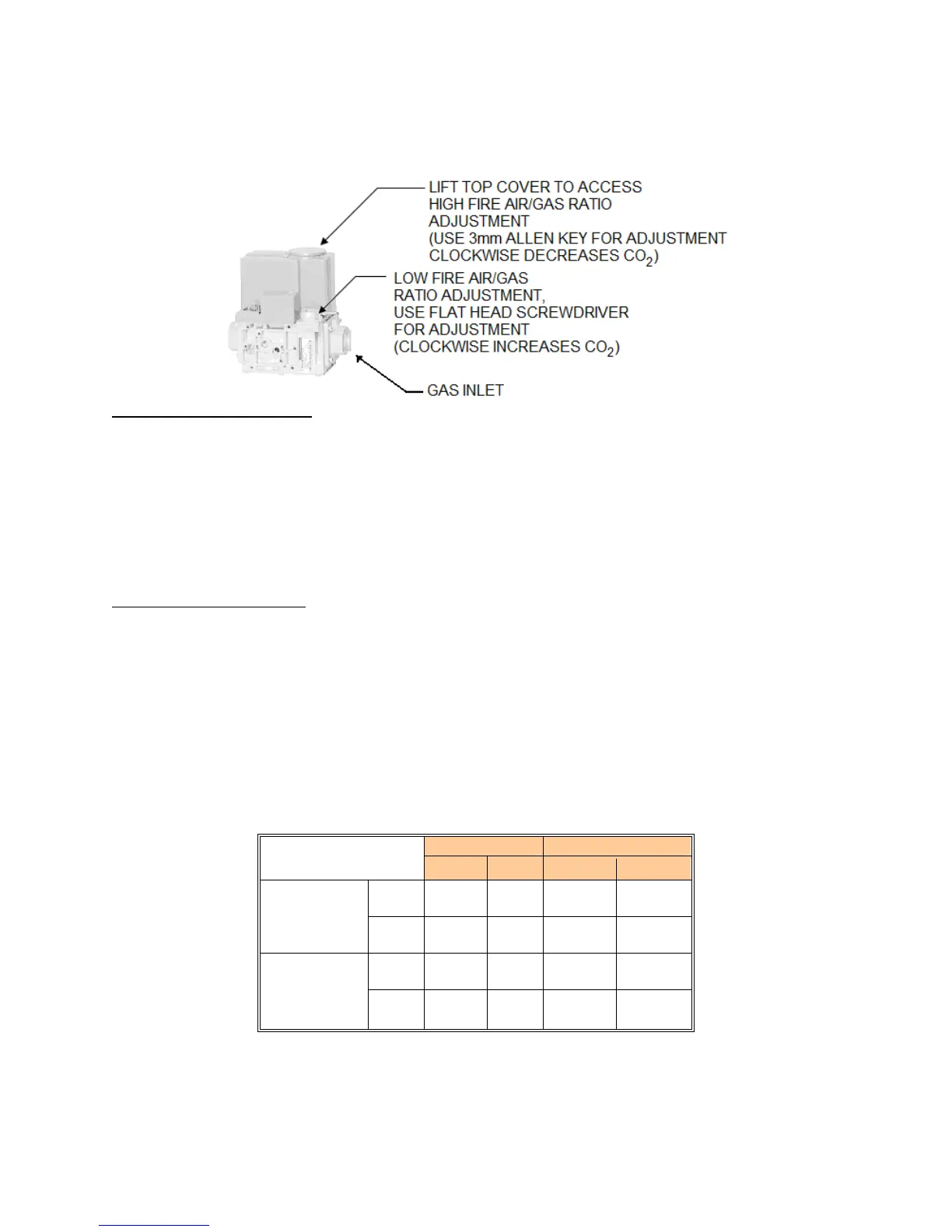

Figure 29: MF 400 – 600 Gas Valve

To adjust the high fire setting

Set the Target Temperature to 190

o

F using the BTC 1 Controller.

Once the appliance is at maximum fan speed locate the input adjustment screw on the top side of the gas

valve. Using a flat head screwdriver turn the screw clockwise to decrease CO

2

levels and counter-

clockwise to increase CO

2

levels. Turn the screw 1/4 turn in either way for each adjustment to keep track

of the adjustments. After adjusting the screw wait a moment for the combustion levels to stabilize before

attempting to make any further adjustments. Continue this procedure until combustion levels are satisfied.

Reset the Target Temperature to normal operating conditions on the BTC 1 Controller.

To adjust the low fire setting

Observe the Boiler Inlet Temperature. Set the Boiler Target temperature so that it is 10

o

F above the Boiler

Inlet Temperature. The boiler will begin to modulate to low-fire as setpoint is being reached. The actual

modulation rate can be shown on the screen as Modulation, this will be shown as a percentage. Low-fire

is achieved at 25%.

The MicoFlame will respond immediately and operate at low fire. When this is achieved locate the low fire

adjustment screw as illustrated in Figure 28. Using a flat screwdriver rotate clockwise to increase CO

2

levels and counter-clockwise to decrease CO

2

levels. When the correct combustion values are achieved

replace the screw cap back on to the gas valve.

Reset the Target Temperature to normal operating conditions on the BTC 1 Controller.

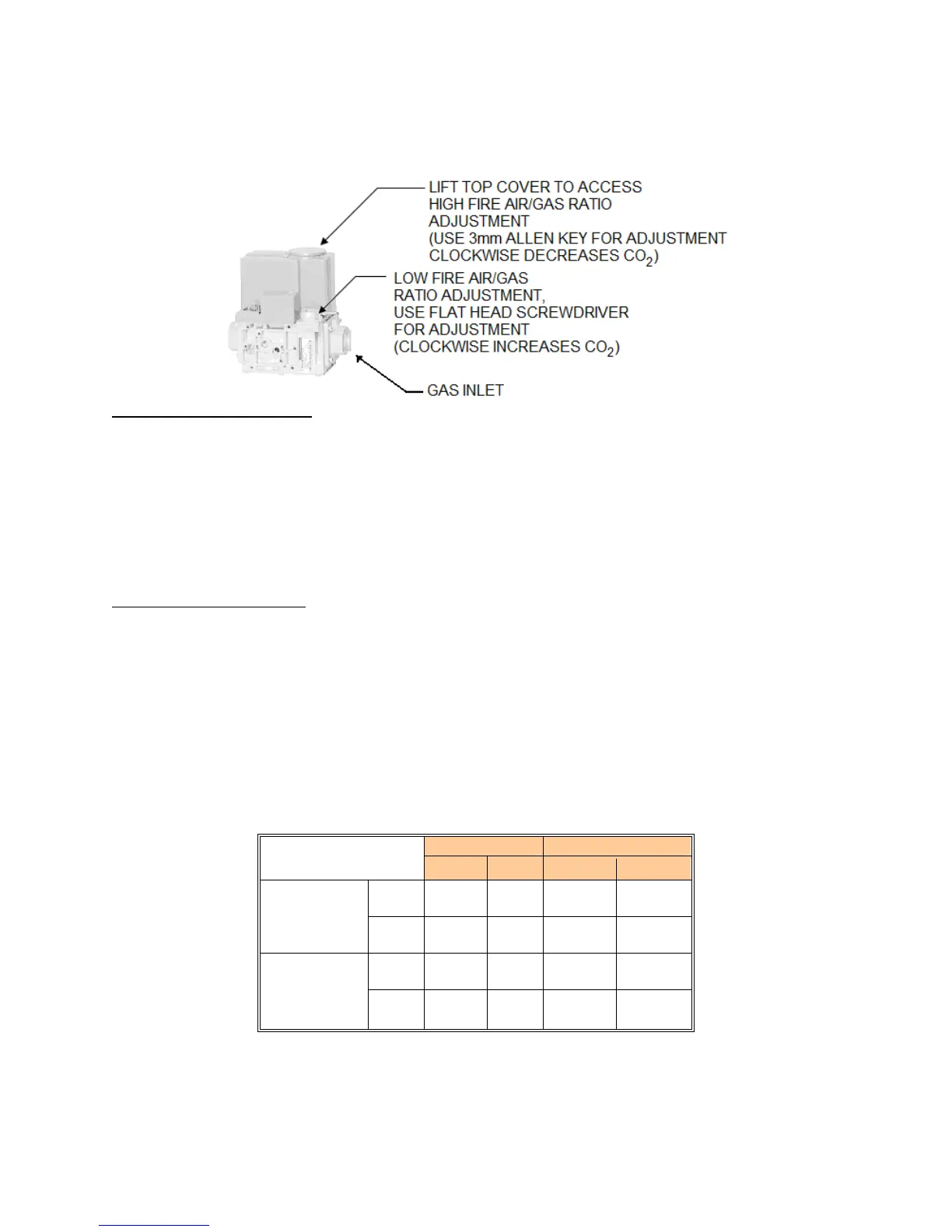

Table 12: Combustion Values

Natural Gas Propane

CO

2

CO CO

2

CO

Max.

Fire

7.5% -

8.5%

< 50

PPM

9.0% -

10.0%

< 50

PPM

Non-

Condensing

Min.

Fire

7.0% -

7.5%

< 50

PPM

8.5% -

9.0%

< 50

PPM

Max.

Fire

8.5% -

9.0%

< 50

PPM

10.0% -

10.5%

< 50

PPM

Condensing

Min.

Fire

7.5% -

8.0%

< 50

PPM

9.0% -

9.5%

< 50

PPM

Loading...

Loading...