62-11648 52

27. Unit Maintenance

27.1 Maintenance Schedule

For the most reliable operation and for maximum life, this unit requires regular

maintenance. This includes oil and filter changes, fuel filter and air cleaner

replacement and coolant replacement.

Maintenance should be performed by properly trained personnel on the

following schedule:

WARNING

!

Unit may start automatically at any time even if the switch is

in the OFF position. Use proper lockout/tagout procedures

before inspection/servicing. All unit inspection/servicing by

properly trained personnel only.

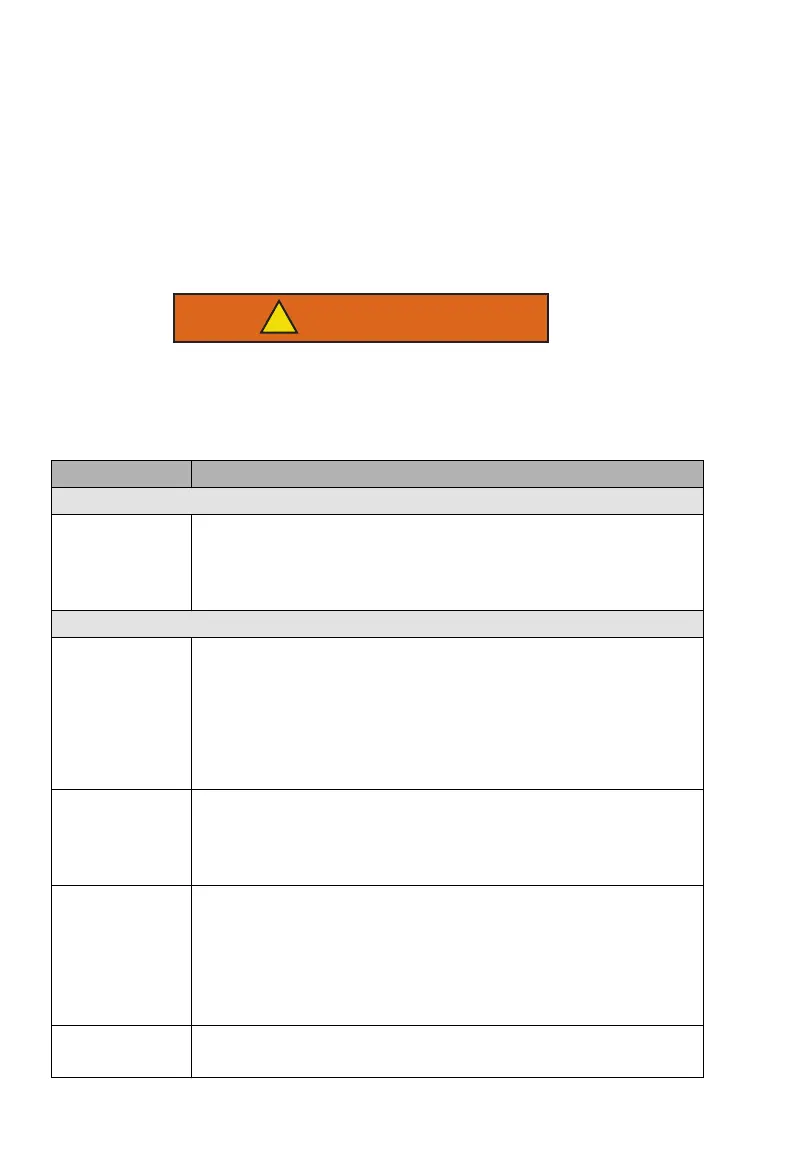

System Operation

Pretrip Inspections

1. Pretrip Inspection - See Pretrip Inspection

2. Run Microprocessor Pretrip - Before loading, see

Pretrip

3. Check Engine Hours

Every Service Interval or Yearly

Engine 1. Check engine oil and filter change interval

2. Check low oil pressure switch

3. Clean crankcase breather

4. Check fuel injectors every 1,500 hours*

5. Check injection pump every 3,000 hours*

6. Check and adjust engine valves every 4,000 hours

Fuel

System

1. Clean mechanical and electric (if equipped) fuel pump

screens

2. Change fuel filter

3. Check fuel heater (if equipped)

Cooling

System

1. Check coolant change interval. If replacement is not

required, check antifreeze concentration using a

refractometer (Carrier Transicold P/N 07-00435-00)

2. Clean condenser/radiator surfaces

3. Check water pump

4. Check water temperature sensor

Exhaust

System

1. Check mounting hardware

2. Check muffler and exhaust pipes

Loading...

Loading...