58TP0B/58TP1B: Installation, Start-up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

44

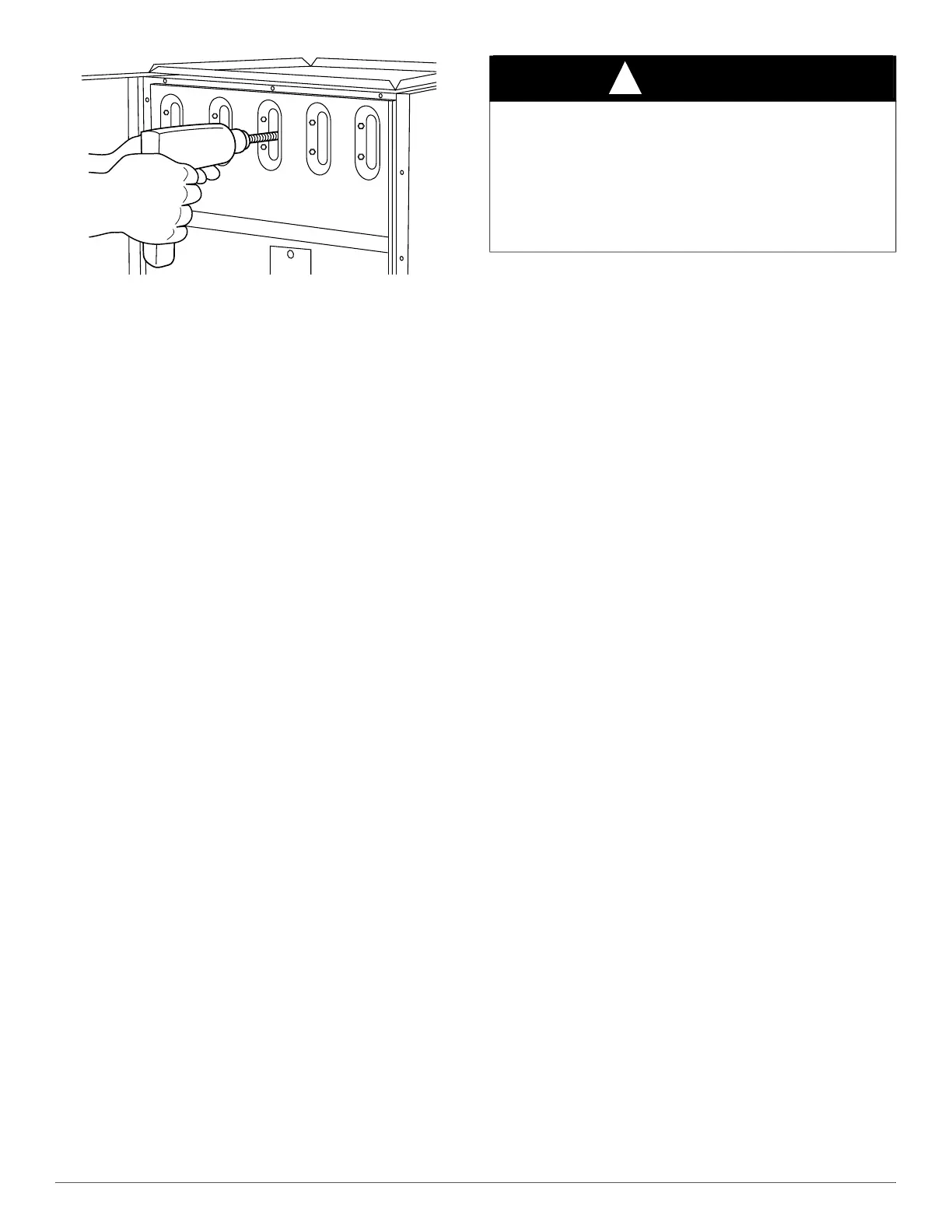

A91252

Fig. 51 – Cleaning Heat Exchanger Cell

(3.) Work cable in and out of cell 3 or 4 times to obtain

sufficient cleaning. DO NOT pull cable with great force.

Reverse drill and gradually work cable out.

(4.) Insert brush end of cable in burner inlet opening of cell, and

proceed to clean 2 lower passes of cell in same manner as

upper pass.

(5.) Repeat foregoing procedures until each cell in furnace has

been cleaned.

(6.) Using vacuum cleaner, remove residue from each cell.

(7.) Using vacuum cleaner with soft brush attachment, clean

burner assembly.

(8.) Clean flame sensor with fine steel wool.

(9.) Reinstall burner assembly. Center burners in cell openings.

10. Remove old sealant from cell panel and collector box flange.

11. Spray releasing agent on the heat exchanger cell panel where

collector box assembly contacts cell panel.

NOTE: A releasing agent such as cooking spray or equivalent (must not

contain corn or canola oil, aromatic or halogenated hydrocarbons or

inadequate seal may occur) and RTV sealant (G.E. 162, 6702, or

Dow-Corning 738) are needed before starting installation. DO NOT

substitute any other type of RTV sealant. G.E. 162 (P771-9003) is

available through RCD in 3-oz tubes.

12. Apply new sealant to flange of collector box and attach to cell panel

using existing screws, making sure all screws are secure.

13. Reconnect wires to the following components (Use connection

diagram on wiring label, if wires were not marked for reconnection

locations.):

a. Draft safeguard switch.

b. Inducer motor.

c. Pressure switches.

d. Limit over temperature switch.

e. Gas valve.

f. Hot surface igniter.

g. Flame-sensing electrode.

h. Flame rollout switches.

14. Reinstall internal vent pipe, if applicable.

15. Reinstall vent connector on furnace vent elbow. Securely fasten

vent connector to vent elbow with 2 field-supplied,

corrosion-resistant, sheet metal screws located 180_ apart.

16. Replace blower access door only if it was removed.

17. Set thermostat above room temperature and check furnace for

proper operation.

18. Verify blower airflow and speed changes between heating and

cooling.

19. Check for gas leaks.

SEQUENCE OF OPERATION

NOTE: Furnace control must be grounded for proper operation or else

control will lock out. Control is grounded through green/yellow wire

routed to gas valve and burner box screw. Using the schematic diagram

in Fig. 47, follow the sequence of operation through the different modes.

Read and follow the wiring diagram very carefully.

NOTE: If a power interruption occurs during a call for heat (W/W1 or

W/W1-and-W2), the control will start a 90-second blower-only ON

period two seconds after power is restored, if the thermostat is still

calling for gas heating. The LED light will flash code 12 and display will

show (12.1) during the 90-sec period, after which the LED will be ON

continuous, as long as no faults are detected. After the 90-second period,

the furnace will respond to the thermostat normally.

The blower door must be installed for power to be conducted through the

blower door interlock switch ILK to the furnace control CPU,

transformer TRAN, inducer motor IDM, blower motor BLWM,

hot-surface igniter HSI, and gas valve GV.

1. Comfort Heat

®

Technology - Two-Stage Heating (Adaptive

Mode) with Single-Stage Thermostat

See Fig. 30 for thermostat connections

NOTE: Heating Thermostat Type (Htt) can be set to either single stage

(1St) or two-stage (2St) on the control (see the Furnace Control

Programming and Navigation section of this instruction). When set to

(1St), the adaptive heating mode will be used in response to a call for

heat. When the W2 thermostat terminal is energized it will always cause

high-heat operation when the R-to-W circuit is closed, regardless of the

setting of (Htt). This furnace can operate as a two-stage furnace with a

single-stage thermostat because the furnace control CPU includes a

programmed adaptive sequence of controlled operation, which selects

low-heat or high-heat operation. This selection is based upon the stored

history of the length of previous gas-heating periods of the single-stage

thermostat.

The furnace will start up in either low- or high-heat. If the furnace starts

up in low-heat, the control CPU determines the low-heat on-time (from 0

to 16 minutes) which is permitted before switching to high-heat.

If the power is interrupted, the stored history is erased and the control

CPU will select low-heat for up to 16 minutes and then switch to

high-heat, as long as the thermostat continues to call for heat.

Subsequent selection is based on stored history of the thermostat cycle

times.

The wall thermostat “calls for heat”, closing the R-to-W circuit. The

furnace control performs a self-check, verifies the low-heat and

high-heat pressure switch contacts LPS and HPS are open, and starts the

inducer motor IDM in high-speed.

a. Inducer Prepurge Period

(1.) If the furnace control CPU selects low-heat operation the

inducer motor IDM comes up to speed, the low-heat

pressure switch LPS closes, 24 VAC power is supplied for a

field installed humidifier at the HUM terminal and the

furnace control CPU begins a 15-second prepurge period. If

the low-heat pressure switch LPS fails to remain closed the

inducer motor IDM will remain running at high-speed.

After the low-heat pressure switch re-closes the furnace

WARNING

!

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal injury, death,

and/or property damage.

Never purge a gas line into a combustion chamber. Never test for gas

leaks with an open flame. Use a commercially available soap solution

made specifically for the detection of leaks to check all connections. A

fire or explosion may result causing property damage, personal injury

or loss of life.

Loading...

Loading...