26

REFRIGERANT FLOW--CONTROL

DEVICES

THERMOSTATIC EXPANSION VALVES (TXV)

The FX4, FV4, FF1E and FE4 Fan Coils are factory equipped with

a hard shutoff (HSO) TXV. The hard shutoff TXV has no bleed

port and allows no bleed--through after system is shutdown.

The TXV is a bi--flow metering device that is used in condensing

and heat pump systems to adjust to changing load conditions by

maintaining a preset superheat temperature at outlet of evaporator

coil. The volume of refrigerant metered through valve seat is

dependent upon the following:

1. Superheat temperature sensed by sensing bulb on suction

tube at outlet of evaporator coil. As long as this bulb con-

tains some liquid refrigerant, this temperature is converted

into pressure pushing downward on the diaphragm, which

opens the valve via push rods.

2. The suction pressure at outlet of evaporator coil is trans-

ferred via the external equalizer tube to underside of dia-

phragm.

The bi--flow TXV is used on split system heat pumps. In cooling

mode, TXV operates the same as a standard TXV previously

explained. However, when system is switched to heating mode of

operation, refrigerant flow is reversed.

The bi--flow TXV has an additional internal check valve and

tubing. These additions allow refrigerant to bypass TXV when

refrigerant flow is reversed with only a 1--psig to 2--psig pressure

drop through device.

When heat pump switches to defrost mode, refrigerant flows

through a completely open (not throttled) TXV. The bulb senses

the residual heat of outlet tube of coil that had been operating in

heating mode (about 85_ F and 155 psig). This temporary,

not--throttled valve decreases indoor pressure drop, which in turn

increases refrigerant flow rate, decreases overall defrost time, and

enhances defrost efficiency.

PROBLEMS AFFECTING TXV

A. Low Suction Pressure

1.RestrictioninTXV

2. Low refrigerant charge

3. Low indoor load

4. Low evaporator airflow

B. High Suction Pressure

1. Overcharging

2. Sensing bulb not secure to vapor tube

3. High indoor load

4. Large evaporator face area

NOTE: When installing or removing TXV, wrap TXV with a wet

cloth. When reattaching TXV, make sure sensing bulb is in good

thermal contact with suction tube.

5. The needle valve on pin carrier is spring--loaded, which also

exerts pressure on underside of diaphragm via push rods,

which closes valve. Therefore, bulb pressure equals evapor-

ator pressure at outlet of coil plus spring pressure. If load

increases, temperature increases at bulb, which increases

pressure on topside of diaphragm, which pushes pin carrier

away from seal, opening valve and increasing flow of refri-

gerant. The increased refrigerant flow causes increased leav-

ing evaporator pressure which is transferred via the equal-

izer tube to underside of diaphragm, with which the pin

carrier spring pressure closes valve. The refrigerant flow is

effectively stabilized to load demand with negligible change

in superheat.

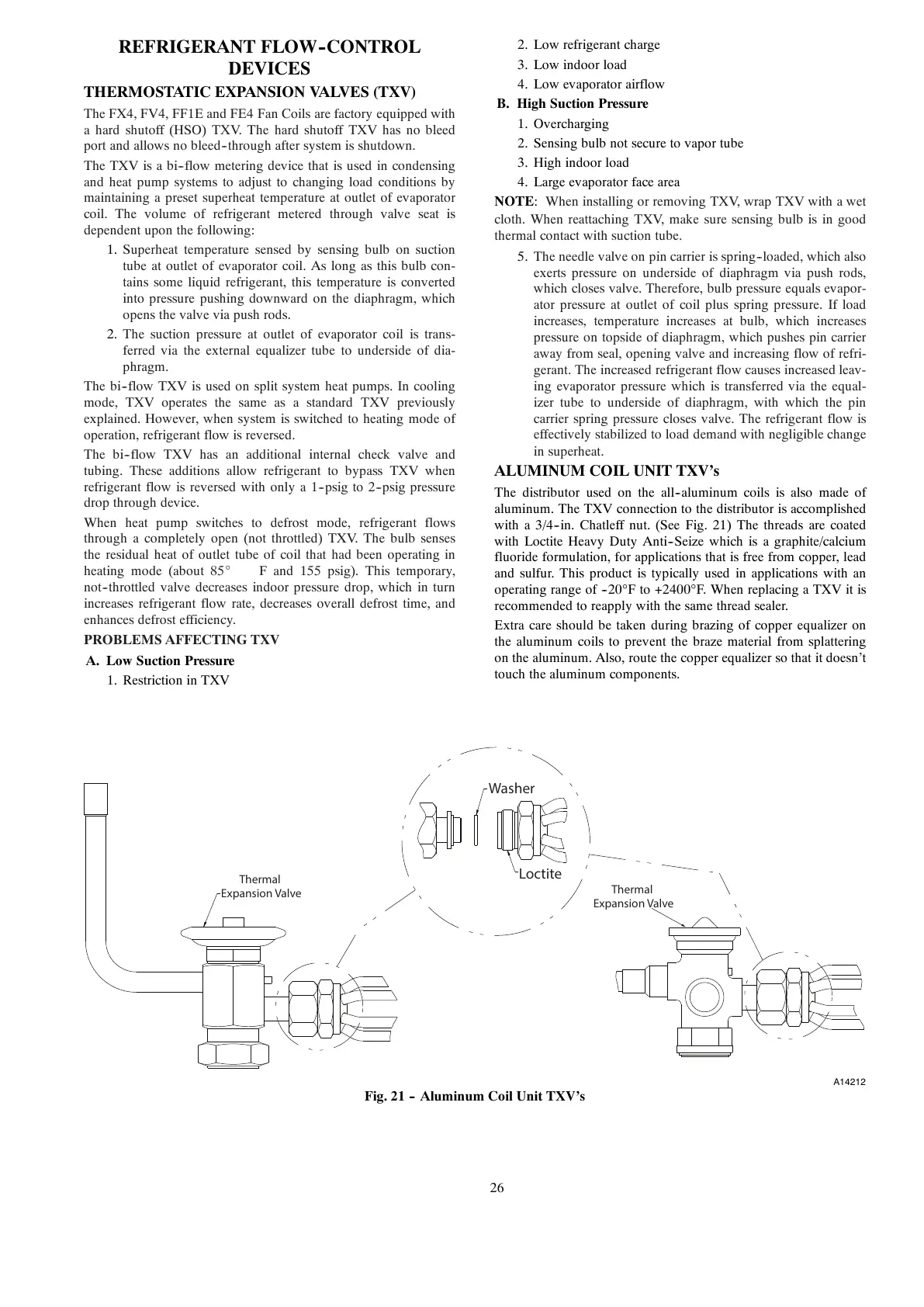

ALUMINUM COIL UNIT TXV’s

The distributor used on the all--aluminum coils is also made of

aluminum. The TXV connection to the distributor is accomplished

with a 3/4--in. Chatleff nut. (See Fig. 21) The threads are coated

with Loctite Heavy Duty Anti--Seize which is a graphite/calcium

fluoride formulation, for applications that is free from copper, lead

and sulfur. This product is typically used in applications with an

operating range of --20°F to +2400°F. When replacing a TXV it is

recommended to reapply with the same thread sealer.

Extra care should be taken during brazing of copper equalizer on

the aluminum coils to prevent the braze material from splattering

on the aluminum. Also, route the copper equalizer so that it doesn’t

touch the aluminum components.

Loctite

Washer

Thermal

Expansion Valve

Thermal

Expansion Valve

A14212

Fig. 21 -- Aluminum Coil Unit TXV’s

Loading...

Loading...