5

312753

T-O-D 60TX11

HH19ZA945

C9725

L145-55F

312753

T-O-D 60TX11

HH19ZA945

C9725

L145-55F

SPT

FAN

RELAY

NO

NC

5

PULL TO OPEN

WARNING

ELECTRIC SHOCK

HAZARD

DISCONNECT

REMOTE POWER

SUPPLY BEFORE

OPENING PANEL.

322861-101 REV. A

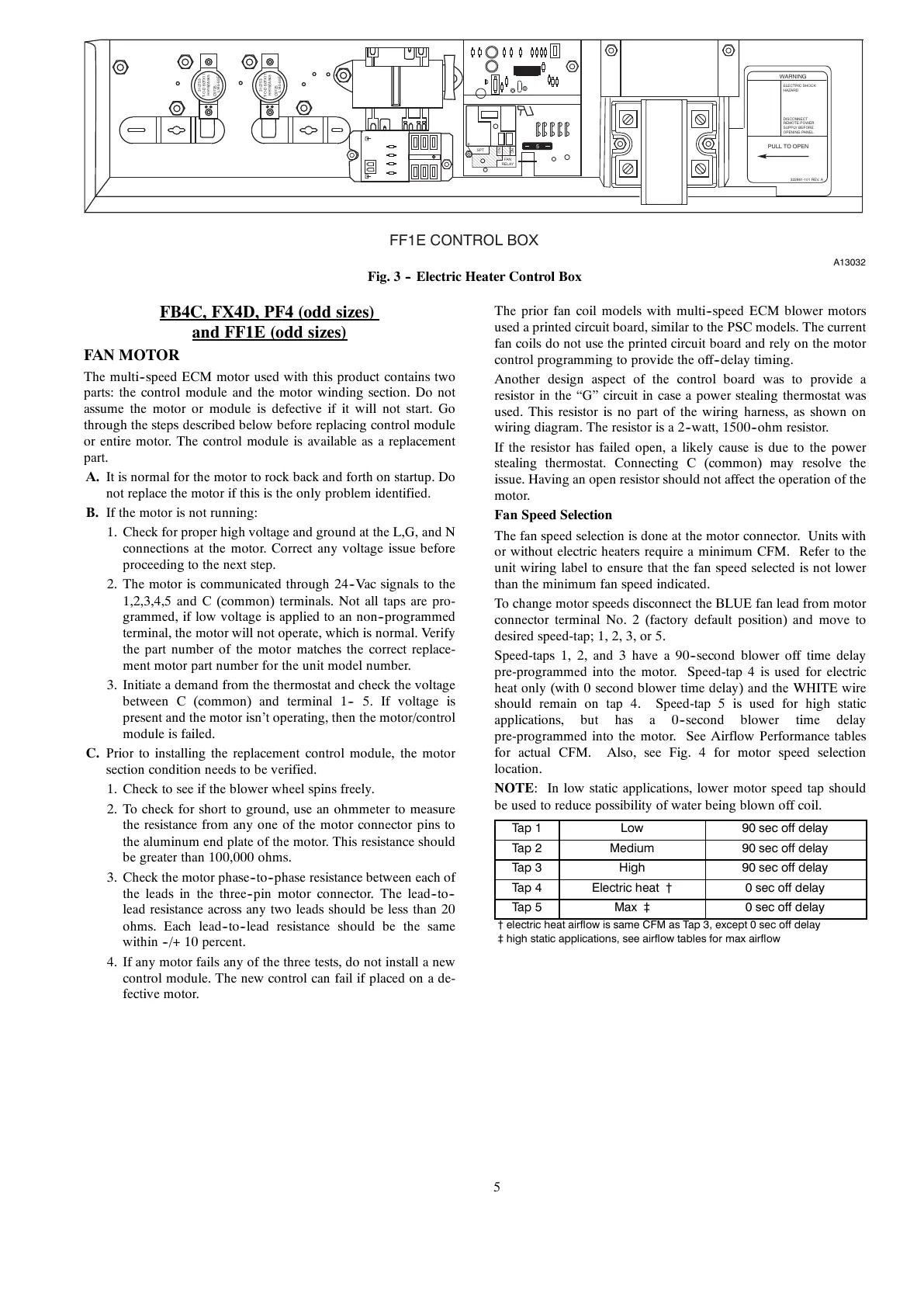

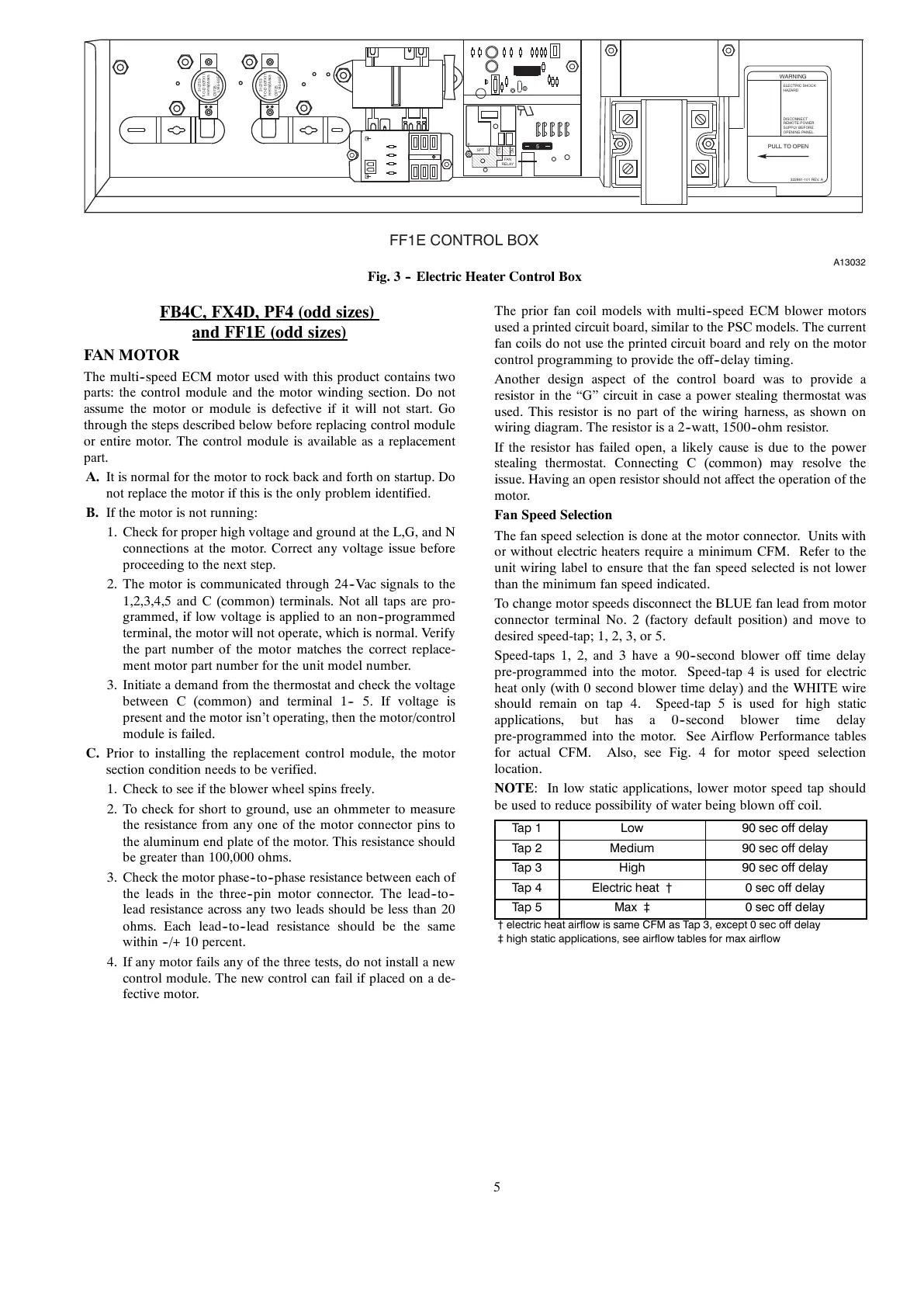

FF1E CONTROL BOX

A13032

Fig. 3 -- Electric Heater Control Box

FB4C, FX4D, PF4 (odd sizes)

and FF1E (odd sizes)

FAN MOTOR

The multi--speed ECM motor used with this product contains two

parts: the control module and the motor winding section. Do not

assume the motor or module is defective if it will not start. Go

through the steps described below before replacing control module

or entire motor. The control module is available as a replacement

part.

A. It is normal for the motor to rock back and forth on startup. Do

not replace the motor if this is the only problem identified.

B. If the motor is not running:

1. Check for proper high voltage and ground at the L,G, and N

connections at the motor. Correct any voltage issue before

proceeding to the next step.

2. The motor is communicated through 24--Vac signals to the

1,2,3,4,5 and C (common) terminals. Not all taps are pro-

grammed, if low voltage is applied to an non--programmed

terminal, the motor will not operate, which is normal. Verify

the part number of the motor matches the correct replace-

ment motor part number for the unit model number.

3. Initiate a demand from the thermostat and check the voltage

between C (common) and terminal 1-- 5. If voltage is

present and the motor isn’t operating, then the motor/control

module is failed.

C. Prior to installing the replacement control module, the motor

section condition needs to be verified.

1. Check to see if the blower wheel spins freely.

2. To check for short to ground, use an ohmmeter to measure

the resistance from any one of the motor connector pins to

the aluminum end plate of the motor. This resistance should

be greater than 100,000 ohms.

3. Check the motor phase--to--phase resistance between each of

the leads in the three--pin motor connector. The lead--to--

lead resistance across any two leads should be less than 20

ohms. Each lead--to--lead resistance should be the same

within --/+ 10 percent.

4. If any motor fails any of the three tests, do not install a new

control module. The new control can fail if placed on a de-

fective motor.

The prior fan coil models with multi--speed ECM blower motors

used a printed circuit board, similar to the PSC models. The current

fan coils do not use the printed circuit board and rely on the motor

control programming to provide the off--delay timing.

Another design aspect of the control board was to provide a

resistor in the “G” circuit in case a power stealing thermostat was

used. This resistor is no part of the wiring harness, as shown on

wiring diagram. The resistor is a 2--watt, 1500--ohm resistor.

If the resistor has failed open, a likely cause is due to the power

stealing thermostat. Connecting C (common) may resolve the

issue. Having an open resistor should not affect the operation of the

motor.

Fan Speed Selection

The fan speed selection is done at the motor connector. Units with

or without electric heaters require a minimum CFM. Refer to the

unit wiring label to ensure that the fan speed selected is not lower

than the minimum fan speed indicated.

To change motor speeds disconnect the BLUE fan lead from motor

connector terminal No. 2 (factory default position) and move to

desiredspeed-tap;1,2,3,or5.

Speed-taps 1, 2, and 3 have a 90--second blower off time delay

pre-programmed into the motor. Speed-tap 4 is used for electric

heat only (with 0 second blower time delay) and the WHITE wire

should remain on tap 4. Speed-tap 5 is used for high static

applications, but has a 0--second blower time delay

pre-programmed into the motor. See Airflow Performance tables

for actual CFM. Also, see Fig. 4 for motor speed selection

location.

NOTE: In low static applications, lower motor speed tap should

be used to reduce possibility of water being blown off coil.

Tap 1 Low 90 sec off delay

Tap 2 Medium 90 sec off delay

Tap 3 High 90 sec off delay

Tap 4 Electric heat † 0 sec off delay

Tap 5 Max ‡ 0 sec off delay

† electric heat airflow is same CFM as Tap 3, except 0 sec off delay

‡ high static applications, see airflow tables for max airflow

Loading...

Loading...