61

ECONOMIZER FAULT DETECTION AND DIAGNOSTICS

(FDD) CONTROL

The Economizer Fault Detection and Diagnostics control can

be divided into two tests:

• Test for mechanically disconnected actuator

• Test for stuck/jammed actuator

Mechanically Disconnected Actuator

The test for a mechanically disconnected actuator will be per-

formed by monitoring SAT as the actuator position changes

and the damper blades modulate. As the damper opens, it is ex-

pected SAT will drop and approach OAT when the damper is at

100%. As the damper closes, it is expected SAT will rise and

approach RAT when the damper is at 0%. The basic test will be

as follows:

1. With supply fan running take a sample of SAT at current ac-

tuator position.

2. Modulate actuator to new position.

3. Allow time for SAT to stabilize at new position.

4. Take sample of SAT at the new actuator position and deter-

mine if the damper has opened or closed. If damper has

opened, SAT should have decreased. If damper has closed,

SAT should have increased.

5. Use current SAT and actuator position as samples for next

comparison after next actuator move.

The control will test for a mechanically disconnected damper if

all the following conditions are true:

1. An economizer is installed.

2. The supply fan is running.

3. Conditions are good for economizing.

4. The difference between RAT and OAT is greater than

T24RATDF. It is necessary for there to be a large enough dif-

ference between RAT and OAT in order to measure a change

in SAT as the damper modulates.

5. The actuator has moved at least T24ECSTS %. A very small

change in damper position may result in a very small (or

non-measurable) change in SAT.

6. At least part of the economizer movement is within the range

T24TSTMN% to T24TSTMX%. Because the mixing of

outside air and return air is not linear over the entire range of

damper position, near the ends of the range even a large

change in damper position may result in a very small (or

non-measurable) change in SAT.

Furthermore, the control will test for a mechanically discon-

nected actuator after T24CHDLY minutes have expired when

any of the following occur (this is to allow the heat/cool cycle

to dissipate and not influence SAT):

1. The supply fans switches from OFF to ON.

2. Mechanical cooling switches from ON to OFF.

3. Reheat switches from ON to OFF.

4. The SAT sensor has been relocated downstream of the heat-

ing section and heat switches from ON to OFF.

The economizer will be considered moving if the reported po-

sition has changed at least ± T24ECMDB %. A very small

change in position will not be considered movement.

The determination of whether the economizer is mechanically

disconnected will occur SAT_SEC/2 seconds after the econo-

mizer has stopped moving.

The control will log a “damper not modulating” alert if:

1. SAT has not decreased by T24SATMD degrees F SAT_SET/

2 seconds after opening the economizer at least

T24ECSTS%, taking into account whether the entire move-

ment has occurred within the range 0 to T24TSTMN%.

2. SAT has not increased by T24SATMD degrees F SAT_SET/

2 seconds after closing the economizer at least

T24ECSTS%, taking into account whether the entire move-

ment has occurred within the range T24TSTMX to 100%.

3. Economizer reported position 5% and SAT is not approxi-

mately equal to RAT. SAT not approximately equal to RAT

will be determined as follows:

a. SAT<RAT-(2*2(thermistor accuracy) + 2 (SAT

increase due to fan)) or

b. SAT>RAT+(2*2(thermistor accuracy) + 2 (SAT

increase due to fan))

4. Economizer reported position 95% and SAT is not approxi-

mately equal to OAT. SAT not approximately equal to OAT

will be determined as follows:

a. SAT<OAT-(2*2(thermistor accuracy) + 2 (SAT

increase due to fan)) or

b. SAT>OAT+(2*2(thermistor accuracy) + 2 (SAT

increase due to fan))

The control will test for a jammed actuator as follows:

• If the actuator has stopped moving and the reported posi-

tion (ECONOPOS) is not within ± 3% of the commanded

position (ECONOCMD) after 20 seconds, a “damper stuck

or jammed” alert will be logged.

• If the actuator jammed while opening (i.e., reported posi-

tion is less than the commanded position), a “not econo-

mizing when it should” alert will be logged.

• If the actuator jammed while closing (i.e., reported posi-

tion is greater than the command position), the “economiz-

ing when it should not” and “too much outside air” alerts

will be logged.

The control will automatically clear the jammed actuator alerts

as follows:

• If the actuator jammed while opening, when ECONOPOS

is greater than the jammed position the alerts will be

cleared.

• If the actuator jammed while closing, when ECONOPOS <

jammed position the alerts will be cleared.

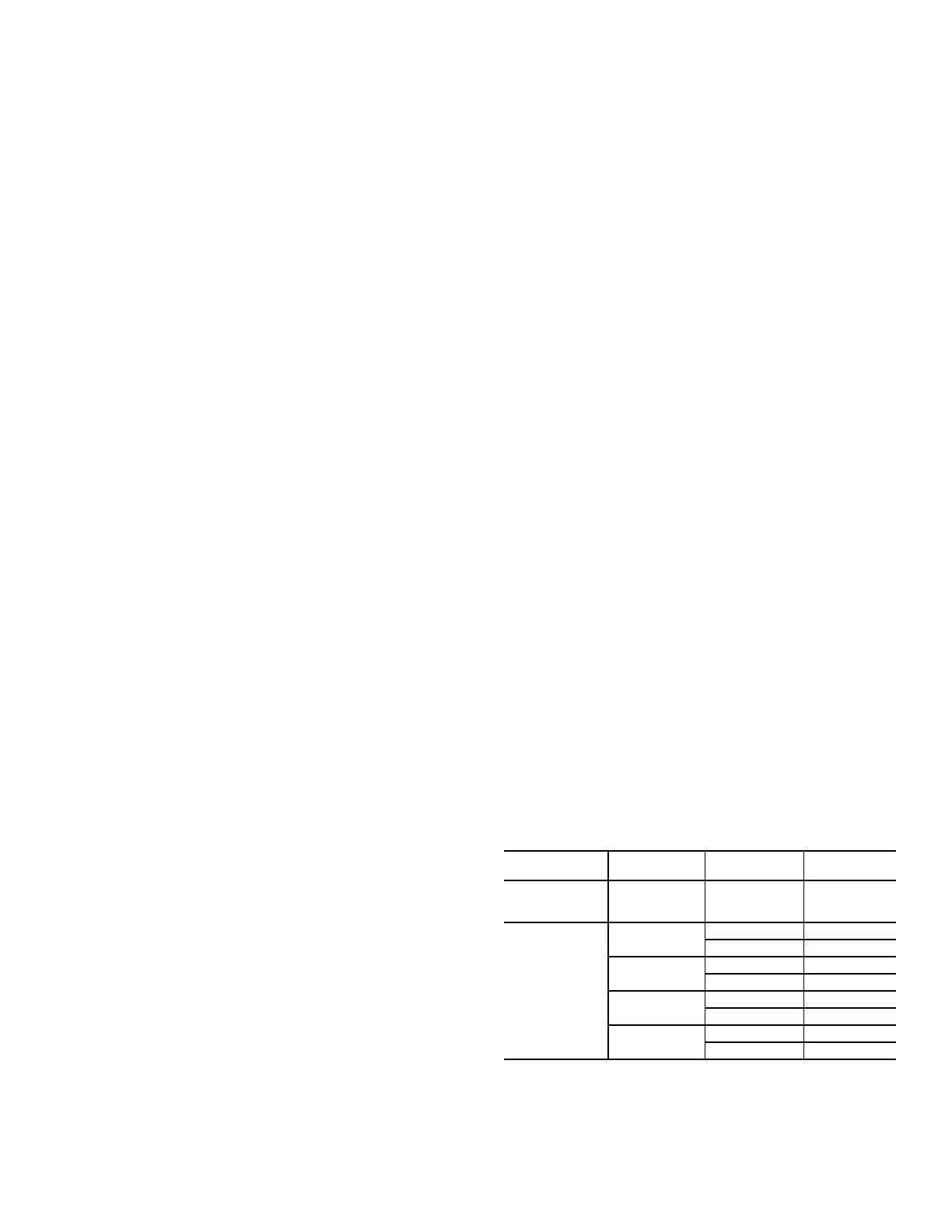

DIFFERENTIAL DRY BULB CUTOFF CONTROL (DIF-

FERENTIAL DRY BULB CHANGEOVER)

As both return air and outside air temperature sensors are in-

stalled as standard on these units, select this option, E.SEL = 1,

to perform a qualification of return and outside-air in the en-

abling/disabling of free cooling. If this option is selected the out-

side-air temperature will be compared to the return-air tempera-

ture to disallow free cooling as shown below:

The status of differential dry bulb cutoff will be visible under

Run Status

ECON

DISA

DDBC.

There will be hysteresis where OAT must fall 1°F lower than

the comparison temperature when transitioning from DDBC-

STAT=YES to DDBSTAT=NO.

E.SEL

(ECON_SEL)

DDB.C

(EC_DDBCO

OAT/RAT

Comparison

DDBC

(DDBCSTAT)

NONE,

OUTDR.ENTH,

DIF.ENTHALPY

N/A N/A NO

DIFF.DRY BULB

0 deg F OAT>RAT YES

OATRAT NO

–2 deg F OAT>RAT-2 YES

OATRAT-2 NO

–4 deg F OAT>RAT-4 YES

OATRAT-4 NO

–6 deg F OAT>RAT-6 YES

OATRAT-6 NO

Loading...

Loading...