230 Series Auger Packer

13 OF 115

The Model 230 Auger Packer consists of the packer

assembly and various items as ordered.

RECEIPT AND INSPECTION

Upon receipt, a check should be made to see that all

items ordered have arrived and are in good condition.

Any damage incurred in shipment should be reported to

the delivering carrier immediately and a claim for the

damage should be filled. If anything is missing or

damaged, contact Choice Bagging Equipment, Ltd. (512-

352-3694) so that replacement or repair can be initiated.

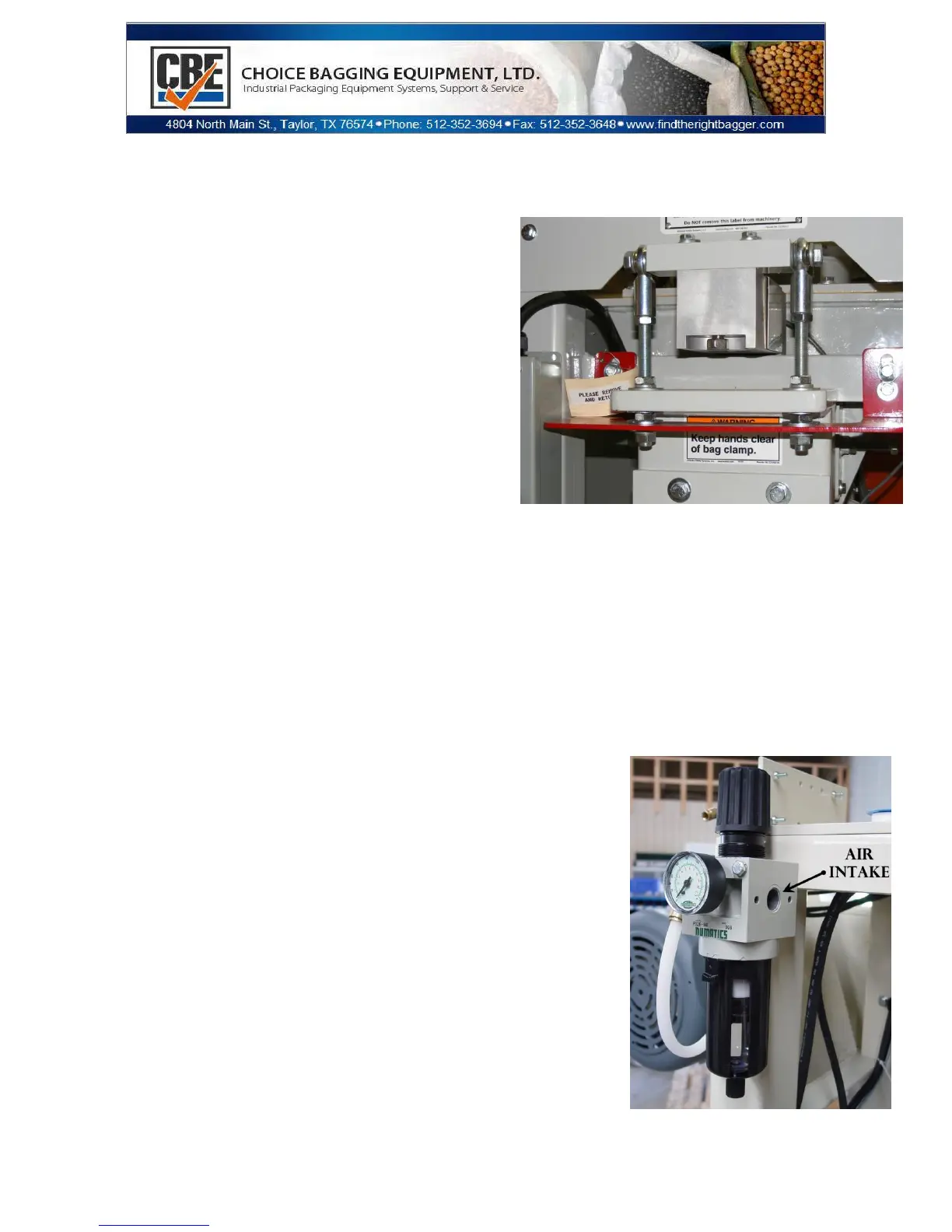

The Model 230 Auger Packer is shipped with locking

bolts installed to secure and protect the bag post and

weighing assembly during shipment. (See Picture)

ASSEMBLY PROCEDURES

Mark the centerlines of the packer, reference the General Arrangement drawing.

Set the packer into place. It may be desirable to defer final anchoring to the floor until after testing. Place

the packer in the proper location, insuring the frame is level. Check the clearance and fit to the feed

hopper and associated piping prior to securing it firmly to the floor.

It is recommended to install a rubber connection sleeve between bin and

hopper to isolate bin vibrations from packers. (Sleeve not provided with

machine. Recommend 0.25” - 0.375” wall thickness. Sleeve can be

purchased from CBE separately).

The weighing assembly is secured by two shipping bolts that protect the

scale from any damage during shipment. Be sure to remove the shipping

bolts located above the bag chair post before attempting to operate the

machine.

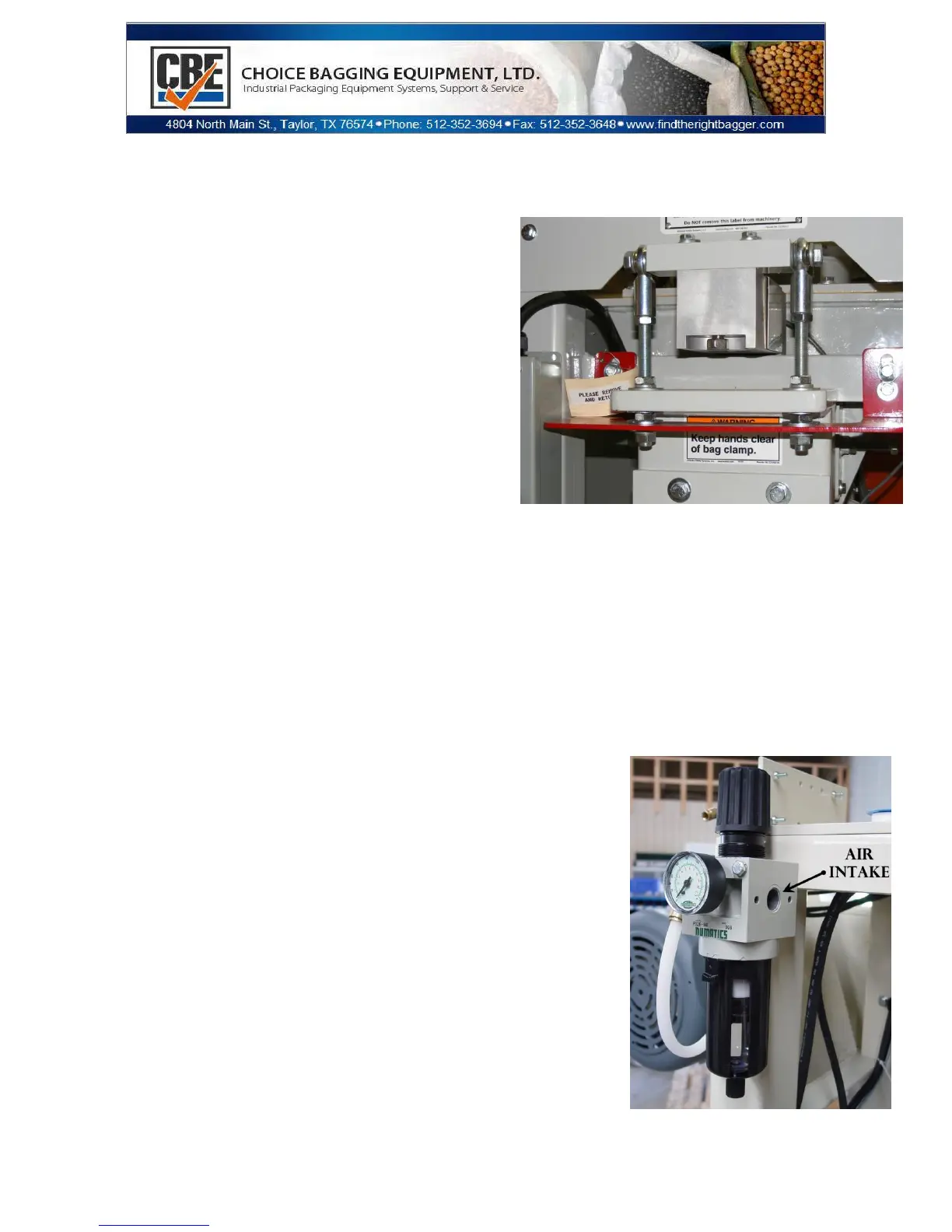

The Model 230 Auger packer uses a load cell scale weighing unit. It is

important to make certain that the load cell and components being

suspended are free from side friction.

Check the alignment of the fill tube to the auger. If adjustments need to

be made to the auger, this is discussed later in Chapter , how to adjust

Loading...

Loading...