Model 108 FLEX-AUGER Installation Manual

*Maximum line lengths should be reduced for elevations over 8’ (2.4 m)

and/or inclines steeper than 45 degrees.

Maximum lengths for 108 systems include use of two PVC elbows. If

additional elbows are used, decrease line length by 30 ft. (9 m) per

elbow. Length of extension systems do not include elbows. Decrease

maximum extension system lengths by 30 ft. (9 m) per elbow if used in

the system.

Horsepower requirements are based on length of the Model 108

FLEX-AUGER system and type of system installed--i.e. number of

turns.

See Model 108 FLEX-AUGER Systems Bin Placement Section (Pages

14 - 17) for typical bin to building placement using various elevations,

boots, and screener options.

1. For the easiest installation and most trouble-free operation, locate

the feed bin in a direct line with the FLEX-AUGER Feed Delivery

System. The layout charts on Pages 14 and 15 provide some points

of reference for bin placement according to the height at which the

Planning the

Model 108 FLEX-AUGER

Feed Delivery System

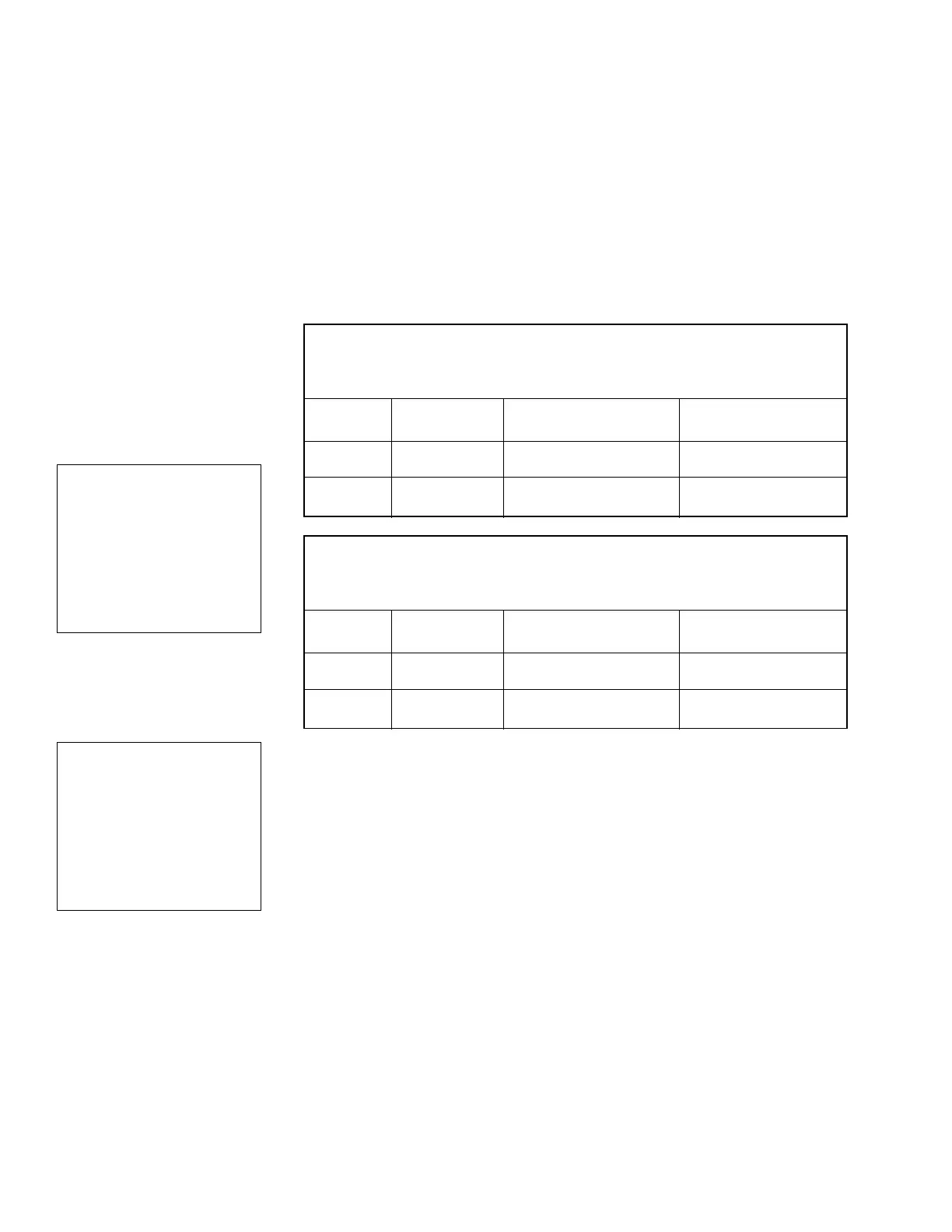

Maximum Line Lengths* for standard 348 RPM Systems

Motor Power Unit Standard Extended

HP Part No. System System

3/4 3259-52 50 Ft. (15.2 m) 75 Ft. (22.8 m)

1 3259-49 100 Ft. (30.5 m) 135 Ft. (41.1 m)

1-1/2 3259-66 150 Ft. (45.7 m) 185 Ft . (56.4 m)

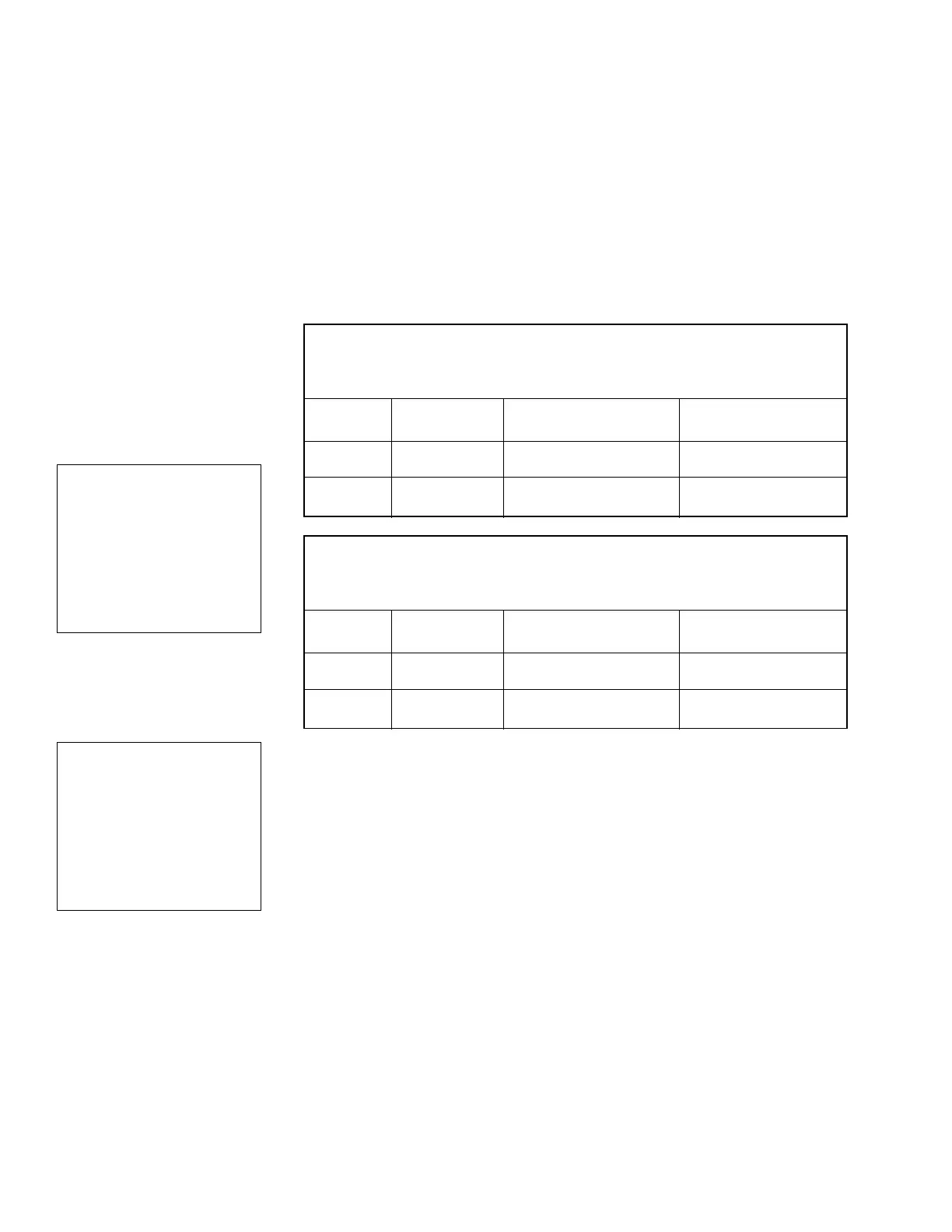

Maximum Line Lengths* for High Capacity 425 RPM Systems

Motor Power Unit Standard Extended

HP Part No. System System

1 3259-79 50 Ft. (15.2 m) 75 Ft. (22.8 m)

1-1/2 3259-80 100 Ft. (30.5 m) 135 Ft. (41.1 m)

2 3259-121 150 Ft. (45.7 m) 185 Ft . (56.4 m)

Carefully plan the Model 108 Fill System installation. Make sure the

system will not interfere with other equipment, doors, windows, etc.

The charts below provide power unit recommendations and maximum

system line lengths. The top chart applies to standard 348 RPM

systems. The lower chart applies to (optional) High Capacity 425 RPM

systems.

High Moisture Corn

Installations:

Reduce the line length

capacity for each Power

Unit by 50% in high

moisture corn

applications

Straight-Thru

Tandem

Installations:

Reduce the line length by

50 ft. (15.2 m) for

Straight-Through

Tandem Systems.

Loading...

Loading...