HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 12.65 D

6

Horizontal package air conditionners

HCompact2 HA

7. LOCATION AND ASSEMBLING

The unit must be handled with care to avoid transport damage. Thus

we recommend:

- For transport in a container, one must be selected that has an easy

load and unload to the installation location.

- Do not dispose of the skids nor the packaging materials until the

machine is in its fi nal location.

- The unit must be lifted and fi xed with care and without inclination

(maximum inclination 15º), since it could harm its operation. Please

refer to the weight and the gravity centre coordinates of each model

stated in the following table.

- The unit is designed to be transported safely by using a forklift truck.

The forks of the forklift truck must ensure that the centre of gravity

of the unit remains within the forks, because a misbalance in the

transport may cause the unit to turn over and fall from the forklift

truck.

Check also that the length of the fork entries, so that the entire

weight-bearing structure of the unit can be supported on the forklift

truck. This also prevents the possible introduction of the truck’s fork

into functional parts of the unit that may cause damage to the unit.

The standards and recommendations of the forklift truck must also

be respected with regards to the maximum load, inclination of the

panel, elevation of the load for transport, and, in particular, the

maximum speed.

6. TRANSPORT

- Finally, the unit must be freed from the skids so that the inserts

available for the silent-blocks can be accessed. Each skid is fi xed

to the crossbar using M4 screws.

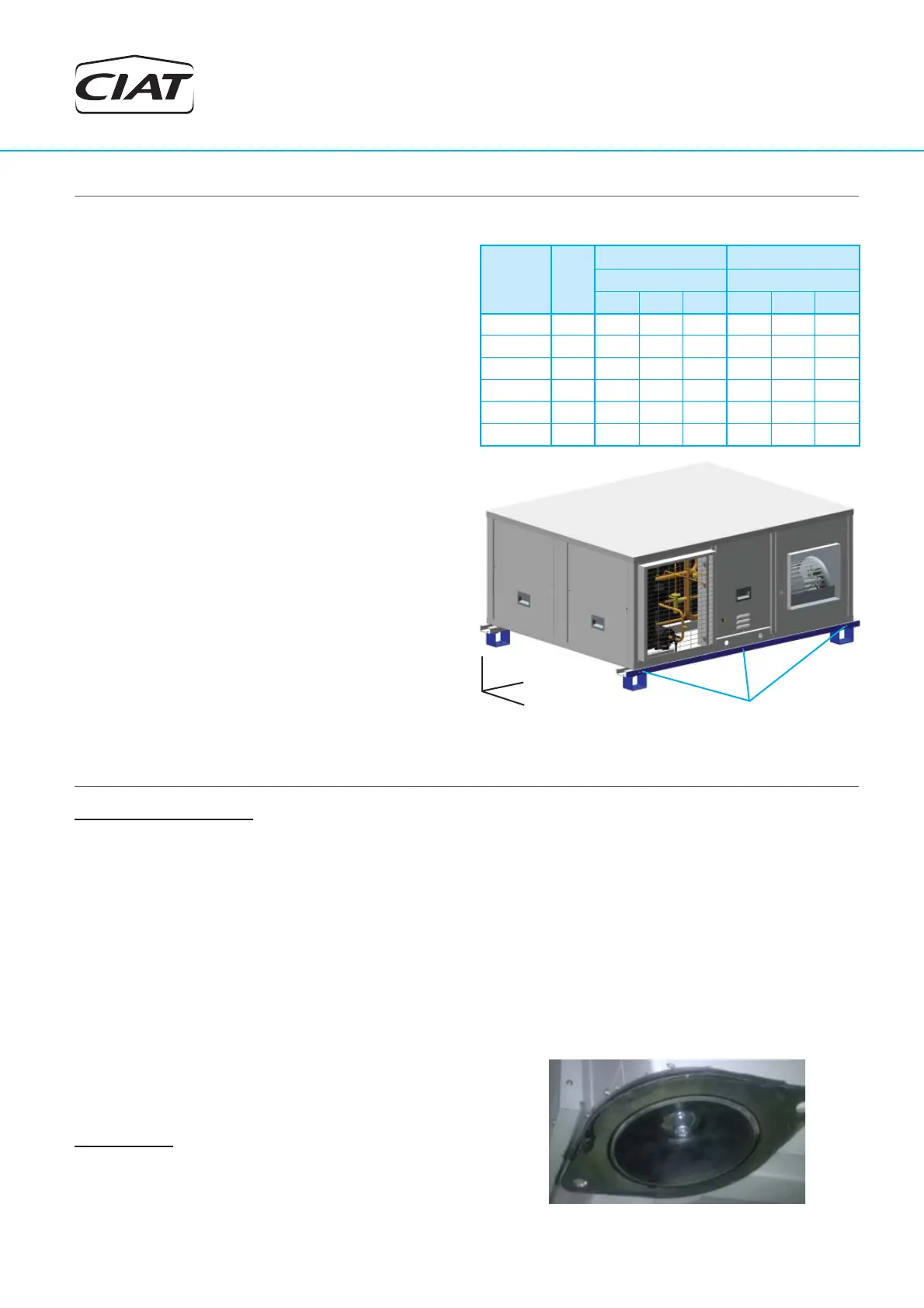

Z

X

Y

skid fi xing screws

HCompact2

HA

Weight

(kg)

M0000 assembly M1111 assembly

Centre of gravity (mm) Centre of gravity (mm)

X Y Z X Y Z

55

245 591 611 266 609 609 266

65

253 585 617 268 603 615 268

80

332 755 746 308 775 743 308

90

375 764 769 307 744 766 307

120

472 1.104 917 340 1.106 906 340

160

521 1.096 921 343 1.097 910 343

Assembling

- These units can be installed on the fl oor or on a brick frame or steel

profi le.

•

Foresee appropriate damping devices in these fi xtures to ensure

that noise and vibration transmission is avoided.

Location designation

Before moving the unit, make sure that all panels are fastened in place.

Lift and lower with care.

When choosing the location, whatever may be the selected fashion, the

following precautions have to be taken into consideration:

- It is mandatory to comply with norm UNE-EN 378-3 on Safety

and Environmental Requirements. Part 3: “In situ” installation and

protection to people.

- The area where the unit will be located must be perfectly accessible

for cleaning and maintenance operations (check minimum free space

for maintenance). Leave enough space for air circulation around the

unit.

- It is necessary to check that the structure supports the unit’s weight

(please see weight in the centre of gravity table)

(please see weight in the centre of gravity table).

• In the event of assembling directly on silent-blocks to the ground,

it is recommended that a template of the unit’s footprint with the

anchoring points of the silent-blocks be made.

• With the help of the crane or the forklift truck, the unit will be raised

to a suffi cient height that the silent-blocks can be screwed into its

base. The 4 silent-blocks must remain oblique to the unit.

• M10 metric threads have been provided for their placement in

the supports indicated in the following section “Anchorage for

silent-blocks”. A hex key 17 or Allen wrench 8 will be used for this

operation based on the type of screw used.

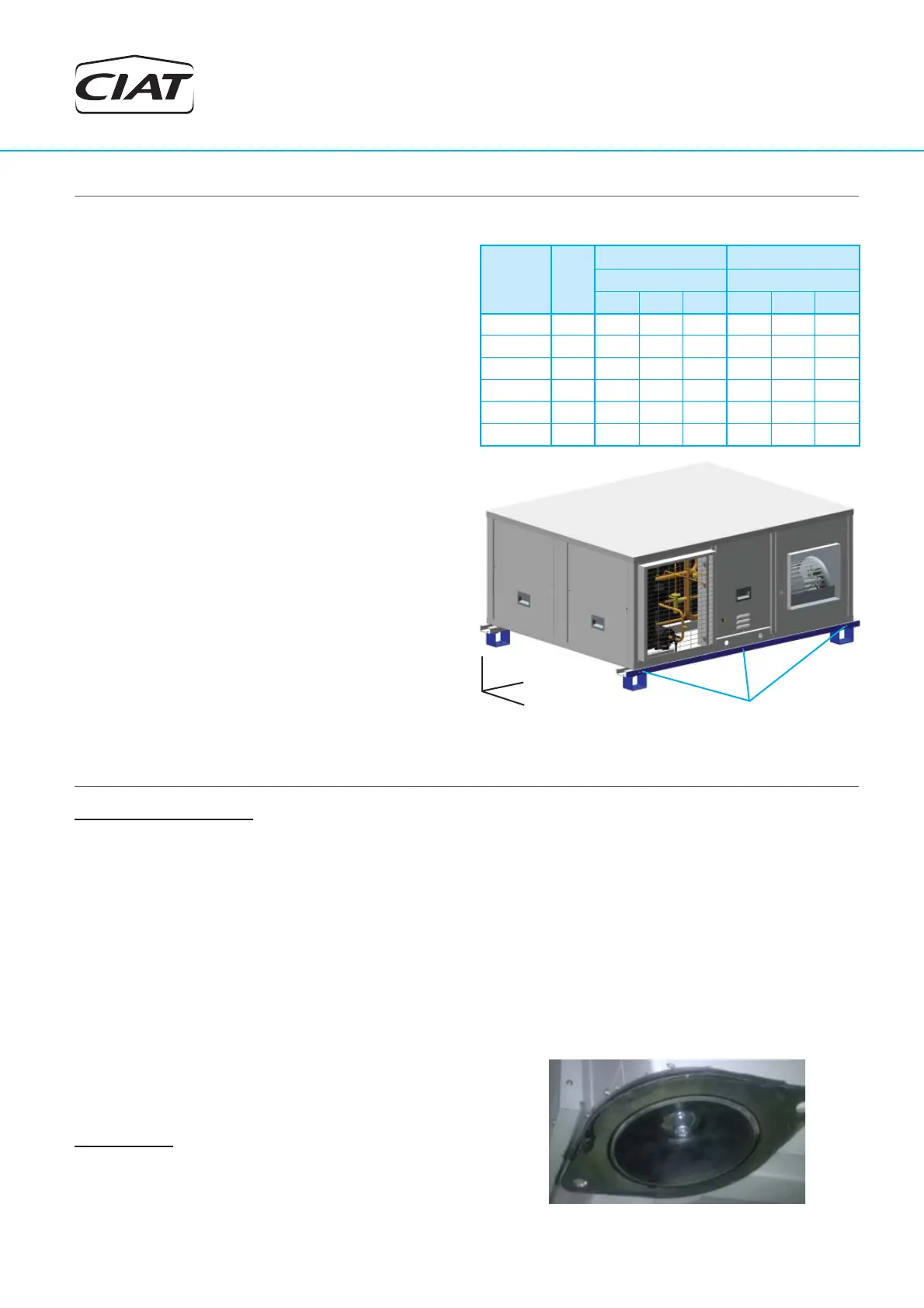

This image shows how the silent-block option that can be supplied

for this unit is fi xed to the unit.

• Check that the unit is perfectly levelled.

Centre of gravity coordinates

Loading...

Loading...