75

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engine : 8HT

Refitting

Preliminary operations

IMPERATIVE :

Check the condition of the seals for the camshaft and the crankshaft pinion. If in doubt don’t

hesitate to change the seals.

Check that there are no leaks at the coolant pump. If in doubt don’t hesitate to change it.

Check that both the tensioner roller and the guide roller can turn freely (no tight spots). If

this is not the case, replace the rollers.

Refitting the belt

IMPERATIVE : Replace the belt as well as the crankshaft pinion screw (12) with new at each

removal. Do not twist or bend the belt.

NOTE : Pegging the high pressure pump serves to increase the life of the timing belt.

NOTE : Use of the tool [6] on the camshaft pinion (23) makes the operation to fit the timing belt easier.

WARNING : The setting pegs have to be in place on the engine.

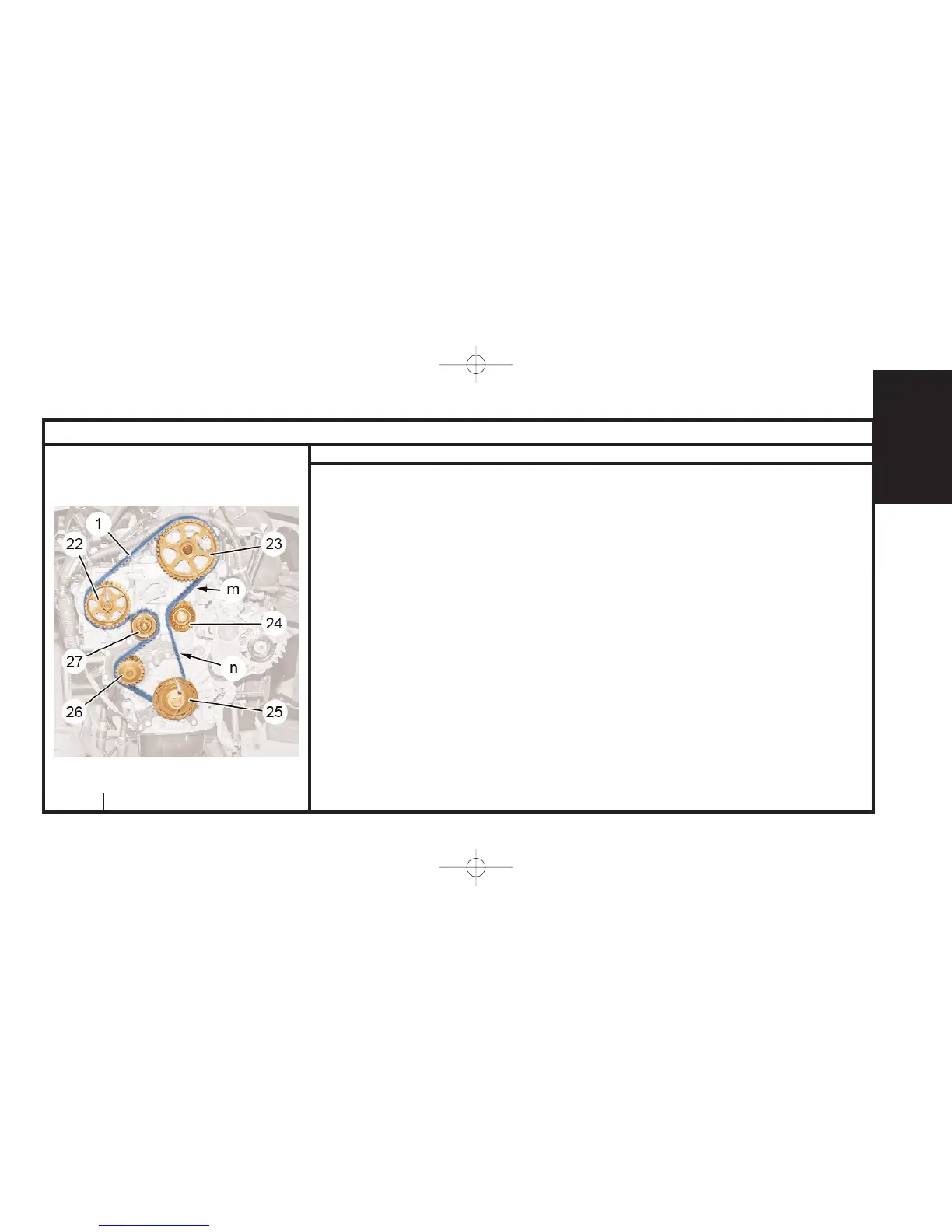

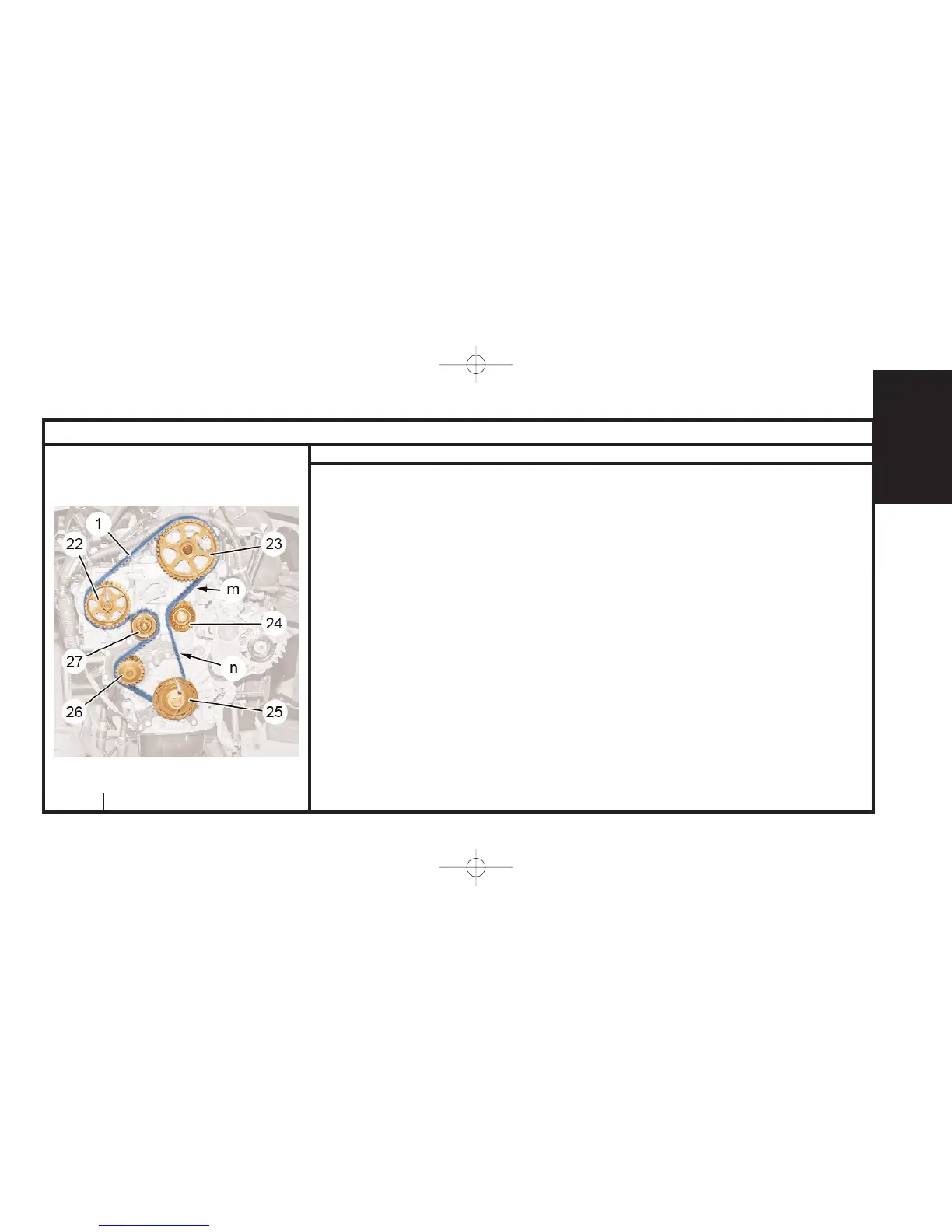

NOTE : If the belt sections "l", "m" and "n" are not kept taut during the tensioning of the belt, the

timing becomes offset. The engine suffers damage.

Reposition the timing belt, sections "l", "m" and "n" kept taut, on the following components :

- Crankshaft pinion (25), guide roller (24), camshaft pinion (23), fuel high pressure pump pulley (22),

coolant pump pinion (26), tensioner roller (27).

B1E2007D

Loading...

Loading...