FSM3 Series

Product-specic cautions

The sensor chip will degrade when used for a long

time and cause the detected ow rate to vary.

Periodically inspect the sensor chip.

Replace the working gas in the ow paths before

changing the gas type.

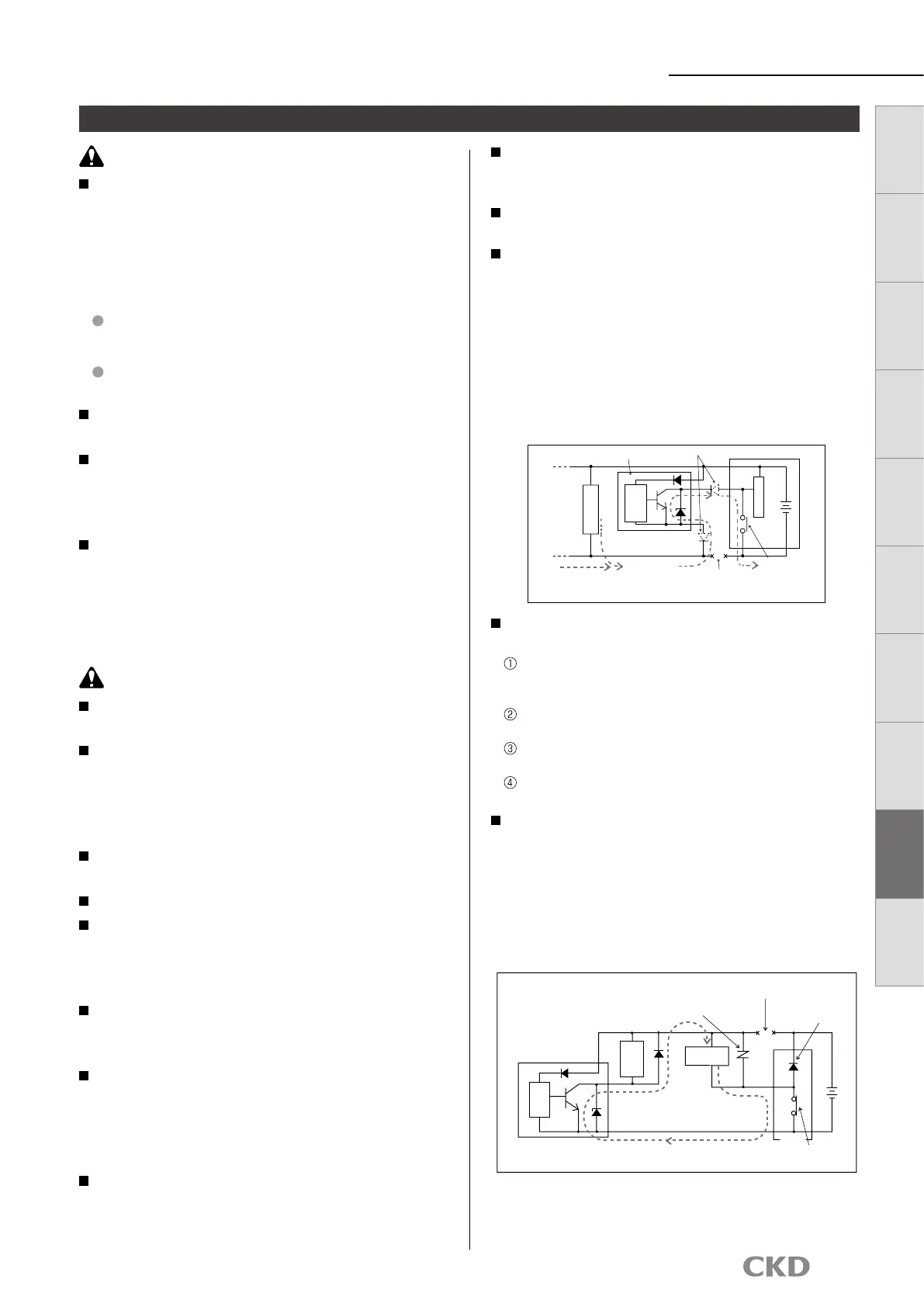

Pay attention to the reverse current caused by

disconnected wires/wiring resistance. If other

devices, including a ow rate sensor, are connected

to the same power sensor as the ow rate sensor,

and the switch output wire and power cable minus

(−) side are short-circuited to check the operation

of the control panel's input unit, or if the power

cable's minus (−) side is disconnected, reverse

current could ow to the ow rate sensor's switch

output circuit and cause damage.

Take countermeasures as followings to prevent

damages caused by reverse current.

Avoid centralizing current at the power cable, especially

the minus side power cable, and use as thick a cable as

possible.

Limit the number of devices connected to the same power

supply as the ow rate sensor.

Insert a diode parallel to the ow rate sensor's output line

to prevent the reverse current.

Insert a diode parallel to the ow rate sensor power wire's

minus (−) side to prevent the reverse current.

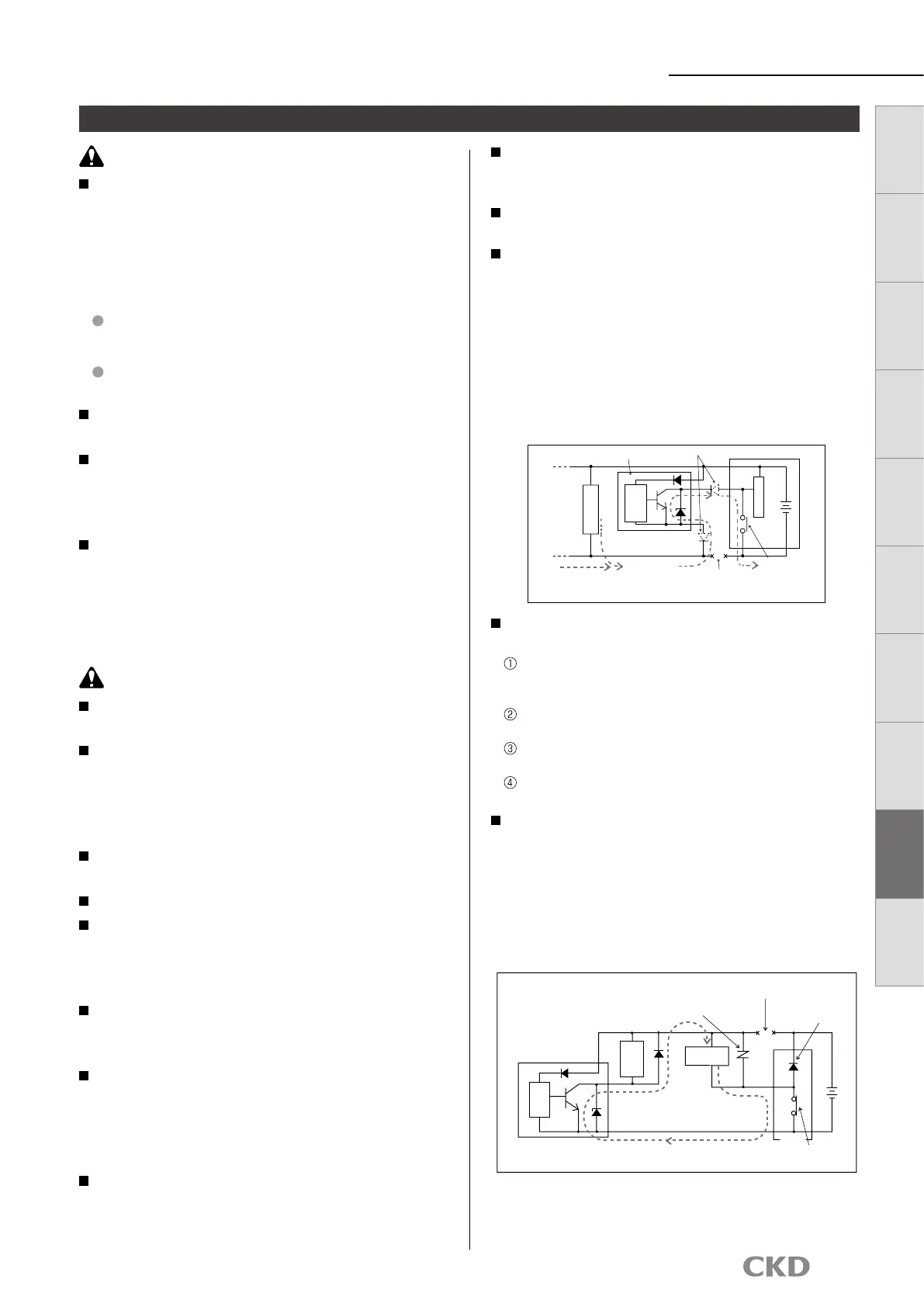

Care must be taken for surge current leading.

When ow rate sensor power is shared with an

inductive load that generates surges, such as a

solenoid valve or relay, if the circuit is cut off while

the inductive load is functioning, surge current

could enter the switch output circuit and cause

damage depending on where the surge absorbing

element is installed.

Working conditions for CE compliance

This product is CE-marked, indicating conformity

with the EMC Directives. EN61000-6-2; regulation

matched to immunity applies to this product.

Conditions below are necessary to comply with

these standards.

Conditions

The assessment of this product is performed by using a

cable pairing a power supply line and a signal line,

treating this cable as a signal line.

This product is not equipped with surge immunity.

Implement surge protection measures on the system side.

Do not disassemble or modify this product. Doing

so could result in faults.

Output accuracy is affected by temperature

characteristics and heat generated when energized.

Provide a standby time (5 minutes or more) after

turning the power ON for use.

Immediately after power is turned ON, this product

does not start ow rate detection switch operation

for approx. 5 seconds to complete self-diagnosis.

Provide a control circuit/program that ignores

signals for at least ve seconds after power is

turned ON.

If a problem occurs during operation, immediately

turn power off, stop use, and contact your dealer.

This product uses a micro-sensor chip, and must

be installed where it will not be subject to dropping,

impact or vibration. Handle this product as a

precision component during installation and

transportation.

Keep this product's ow rate within the rated ow

range.

Use this product within the working pressure range.

Do not turn the product's tting while the uid

pressure is on, since it may cause external leakage.

Also avoid use that may cause the tting to rotate

during operation.

If the output setting value is changed, control

system devices could operate unintentionally. Stop

devices before changing settings.

Analog output continues even if the ow rate range

is exceeded. With the display integrated, "Hi" or

"Lo" will be displayed. With display separated, the

bar display will blink.

Note that this is outside guaranteed precision.

The accuracy may vary from the initial status

depending on the working environment or working

conditions. It is recommended to check the

operation of the product periodically.

During Use & maintenance

Solenoid

valve

Relay

Main

circuit

ON

PLC

PLC output

Surge current

Flow rate sensor

Surge absorbing

element (retrotted)

Circuit cutoff with disconnection

or emergency stop

Surge absorbing

element (built-in)

Diode for reverse ow prevention

Flow rate sensor

Disconnection

Test SW

or short-circuit

Other

components

Current from

Main

circuit

Control panel

CAUTION

WARNING

PLC input

Other components

48

LCD display Bar display

IO

-

Link

Internal

structure

Separate

display

Technical

data

Operating

method

Optional

products

Safety

precautions

Related

products

Loading...

Loading...