14

Specifications

FSM3

Series

*1: The value converted to volumetric ow rate at standard condition (20°C 1 barometric pressure (101 kPa) relative humidity 65%)

*2: Use dry gas which does not contain corrosive elements such as chlorine, sulfur or acids, and which is clean and does not contain dust or

oil mist. When using compressed air, use clean air that complies with JIS B 8392-1:2012 Class 1.1.1 to 1.6.2. Compressed air from the

compressor contains drain (water, oil oxide, foreign substances, etc.) To maintain the function of this product, install a lter, air dryer (min.

pressure dew point 10°C or less), and oil mist lter (max. oil content 0.1 mg/m

3

) on the primary side (upstream side) of this product. (Refer

to the recommended values on page 42.)

*3: Compressed air is used for adjusting and inspecting this product. Accuracy for gas types other than air is a guideline.

*4: The accuracy is based on CKD's basic ow rate meter. It does not show absolute accuracy.

*5: Repeatability over a short period of time. Change over time is not included. (Refer to the product specications sheet for details.)

*6: Actual response time may differ depending on piping conditions.

*7: Current for when 24 VDC is connected, and no load is applied. The current consumption will vary depending on how the load is connected.

*8: The male side is straight and the female side is at an angle. (Refer to page 37.)

Tighten the M12 connector with a torque of 0.5 N·m or lower.

Tightening it using excessive force may lead to damages.

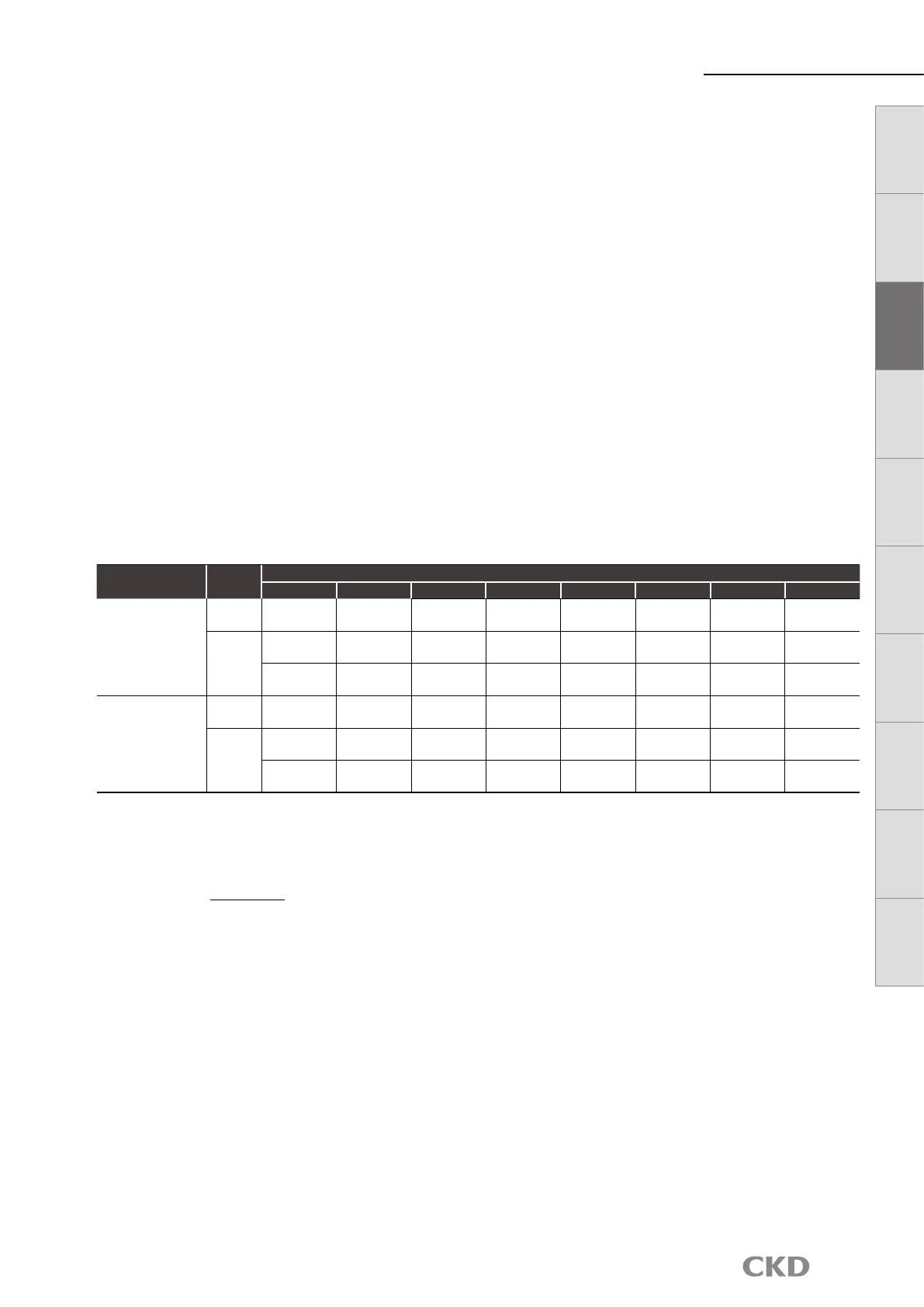

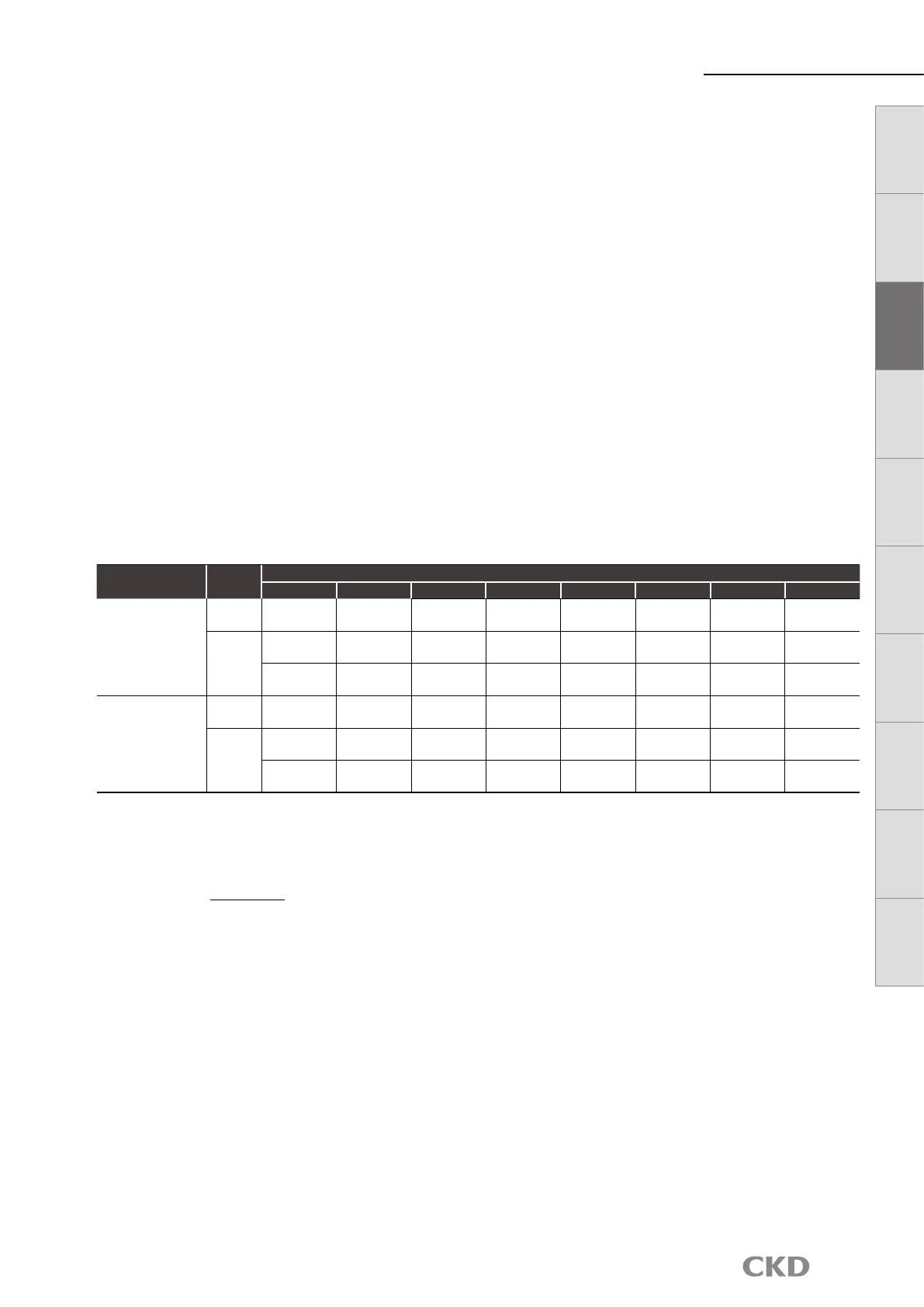

*9: Gas can be changed to argon, carbon dioxide, and argon 80% + carbon dioxide 20% with the gas change function. After changing the gas,

the ow rate measured range will be as follows. (Note that the 500 L/min and 1,000 L/min models do not have a gas change function.)

Gas

Flow

direction

Measured ow rate range (

□

/min)

005 010 020 100 200 500 101 201

Air

Nitrogen

Argon

Argon 80%+

Carbon dioxide 20%

Uni-

direction

15 to

500 mL

30 to

1000 mL

0.06 to

2.00 L

0.30 to

10.00 L

0.6 to 20.0 L 1.5 to 50.0 L

3.0 to

100.0 L

6 to 200 L

Bi-

direction

−500 to

−15 mL

−1000 to

−30 mL

−2.00 to

−0.06 L

−10.00 to

−0.30 L

−20.0 to

−0.6 L

−50.0 to

−1.5 L

−100.0 to

−3.0 L

−200 to −6 L

15 to

500 mL

30 to

1000 mL

0.06 to

2.00 L

0.30 to

10.00 L

0.6 to 20.0 L 1.5 to 50.0 L

3.0 to

100.0 L

6 to 200 L

Carbon dioxide

Uni-

direction

15 to

250 mL

30 to

500 mL

0.06 to

1.00 L

0.30 to

5.00 L

0.6 to 10.0 L 1.5 to 25.0 L 3.0 to 50.0 L 6 to 100 L

Bi-

direction

−250 to

−15 mL

−500 to

−30 mL

−1.00 to

−0.06 L

−5.00 to

−0.30 L

−10.0 to

−0.6 L

−25.0 to

−1.5 L

−50.0 to

−3.0 L

−100 to −6 L

15 to

250 mL

30 to

500 mL

0.06 to

1.00 L

0.30 to

5.00 L

0.6 to 10.0 L 1.5 to 25.0 L 3.0 to 50.0 L 6 to 100 L

The integrating ow is a reference value.

When using the integration maintaining function, be careful that the number of times maintained does not exceed the number of access

times of the storage element (the limit is 1 million times).

(Changes to the settings are not counted in number of accesses.)

Times maintained = < 1 million

Usage time

5 min

*10: This product's protection circuit is effective only for specic misconnections and load short-circuits. It does not provide protection for all

misconnections.

*11: Depending on the vibration conditions, a communication error may occur. Install this product in a place subject to as little vibration as

possible.

*12: This product measures the change in heat distribution caused by ow.

When set to horizontal direction, the convection ow can inuence a change in heat distribution, causing the zero point to shift.

*13: Piping conditions may affect accuracy. For more accurate measurements, use a straight pipe with an internal diameter ten times greater.

With the 500 L/min and 1,000 L/min models, use piping with an internal diameter of 9 mm or more. If it is less than 9 mm, accuracy may

be negatively affected.

*14: Refer to page 32 for weight.

LCD display Bar display

IO

-

Link

Internal

structure

Separate

display

Technical

data

Operating

method

Optional

products

Safety

precautions

Related

products

Loading...

Loading...