Mount an air lter upstream from suction in

compliance with use conditions to prevent the entry

of foreign matter.

Consider the atmospheric dew point and the

product's ambient temperature, and use the product

under conditions in which dew does not condense

in pipes.

When this product is used for vacuum applications

such as air suction, do not bend the tube near the

push-in tting. If stress is applied to the tube near

the push-in tting, insert an insert ring into the tube,

and connect the tube to the push-in tting.

Select the ow rate range based on the operating

vacuum pressure and suction nozzle.

Response speed may be delayed by the piping

volume between the suction nozzle and this

product. In this case, take countermeasures to

reduce piping capacity.

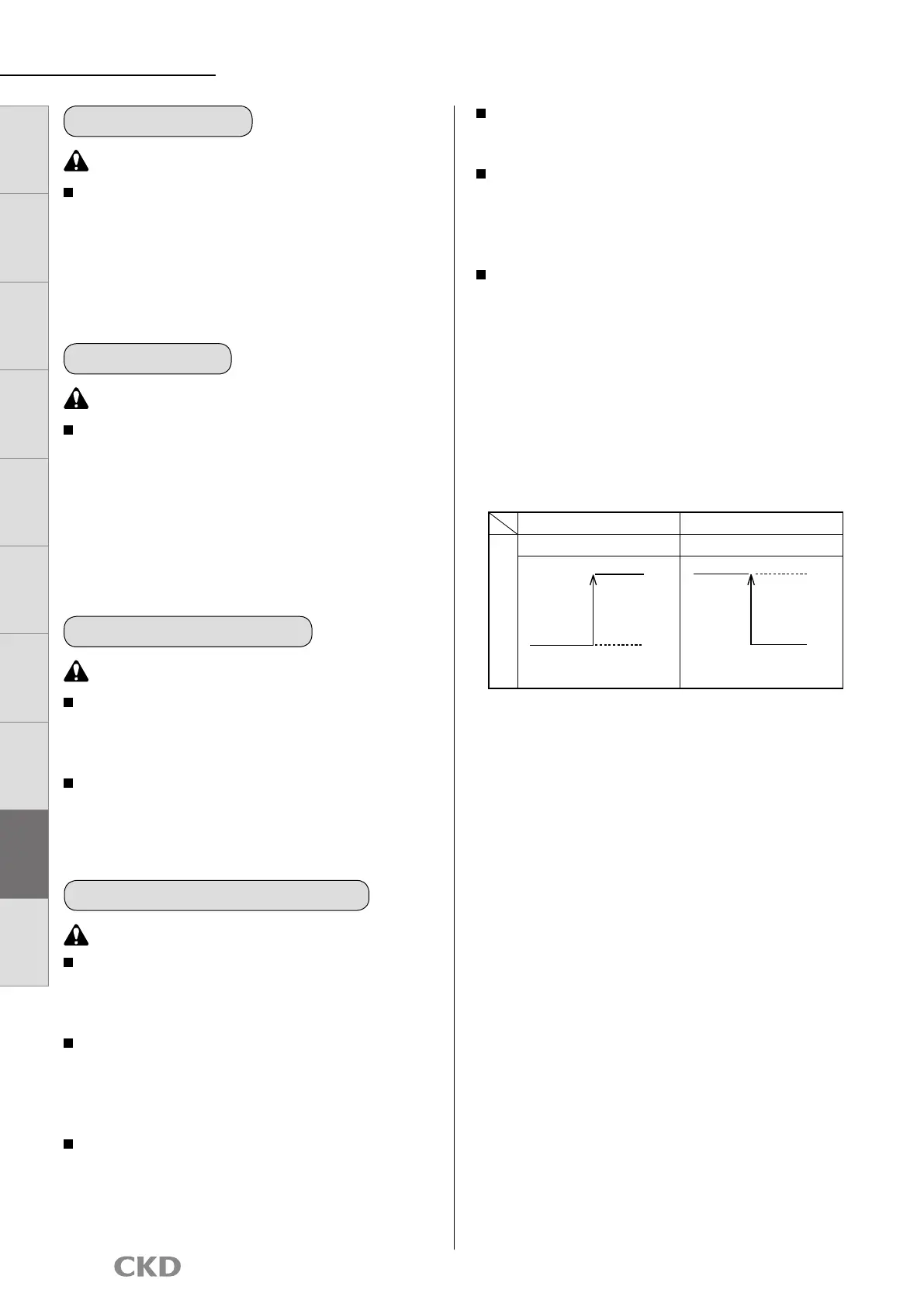

When the suction conrmation sensor is switched

from a pressure sensor (switch) to a ow rate

sensor (switch), sensor output (switch output) logic

will be reversed. Refer to the drawing below.

Note that the PLC sequence program must be

changed or revised.

If source pressure or vacuum source is not supplied

when device power is turned on, "ow rate 0" =

"sensor output (switch output) ON" status is set at

the ow rate sensor (switch). Check that this is not

a problem with the PLC sequence program, etc.

Use for suction conrmation, etc.

Pressure sensor (switch) Flow rate sensor (switch)

Suction conrmation

ON at setting value or more ON at setting value or less

OFF

ON

High ow

rate side

Flow rate 0 sideHigh vacuum

side

OFF

ON

Atmospheric

pressure side

FSM3 Series

CAUTION

CAUTION

This valve cannot be used as a stop valve that

requires no leakage. Slight leakage is allowed

for in this product's specifications.

The flow path in the needle valve is not

completely free of dust generation. A final clean

filter should be used in circuits where dust

generation could be a problem.

Needle valve integrated

CAUTION

This product's flow rate is measured at a mass

flow rate unaffected by temperature or pressure.

The unit is ℓ/min, the display used when the

mass flow rate is converted to volumetric flow

rate at 20°C, 1 barometric pressure (101 kPa),

relative humidity 65%.

(For gases other than air, 20°C, 1 atmospheric

pressure (101 kPa), relative humidity 0% RH.)

Flow rate unit

CAUTION

With each series, the sensor can handle an

overflow double the measured range. If dynamic

pressure is applied near the maximum working

pressure (when a pressure difference exceeding

the max. working pressure is applied between

primary and secondary sides), the sensor may

operate abnormally. If dynamic pressure is applied,

such as when a workpiece is filled for leakage

inspection, provide a bypass circuit or restrictor so

that dynamic pressure is not applied to the sensor.

Overflow

45

LCD displayBar display

IO

-

Link

Internal

structure

Separate

display

Technical

data

Operating

method

Optional

products

Safety

precautions

Related

products

Loading...

Loading...