Always attach the pipes before starting wiring.

Align the uid ow direction to the direction

indicated on the pipe when connecting the pipes.

Do not install the regulator/solenoid valve, etc.,

immediately before this product. Generated drift

may cause errors. Provide a straight piping section

if required.

Before installing piping, clean out the pipes using

air blower to remove all foreign matter and cutting

chips from the pipes. The rectier or sensor chip

could be damaged if a large amount of foreign

matter, cutting chips, etc., enters.

Check that sealant tape or sealant material does not

get inside during piping.

*When using for clean room specications, make

sure that the sealant material matches the system.

The screw-in ttings of this product are compliant

with push-in ttings for pneumatic pressure. Do not

use this product for pneumatic pressure circuits

with steel pipe connections. If this product is used

for steel pipe connection, the misalignment of the

IN side steel pipe bore and OUT side steel pipe

bore will cause excessive force to be applied to the

body, as well as external leakage, risking damage

to the product.

Attach a wrench to metal sections

when tightening pipes so that force is

not applied to the resin section.

Refer to the torque below so as not to

apply excessive screw-in torque or load

torque to the connection port.

When using a push-in tting, accurately insert tube

and conrm that it cannot be pulled out. Cut the tube

at a right angle with a dedicated cutter before use.

Make sure that the leakage detection solution does not

enter the product when inspecting the pipe for leaks.

Do not turn the tting while the product uid

pressure is on, since it may cause external leakage.

The LCD display type ow rate display meter uses

a liquid crystal display. This may be difcult to read

depending on the angle.

Do not install multiple product bodies in close

contact. The generation of heat on each part could

cause the product's temperature to rise, hastening

changes in characteristics or deterioration of the

resin material. When using the products in a row,

set intervals of distance of 10 mm and over.

Although the mounting is "unrestricted in vertical/

horizontal direction", the ow rate may vary

depending on difference in the mounting orientation

or piping conditions.

Mounting, installation and adjustment

Piping

Mounting

CAUTION

[

Reference value]

Port thread Tightening torque N·m

Rc1/8(G1/8) 3 to 5

Rc1/4 6 to 8

Rc1/2 16 to 18

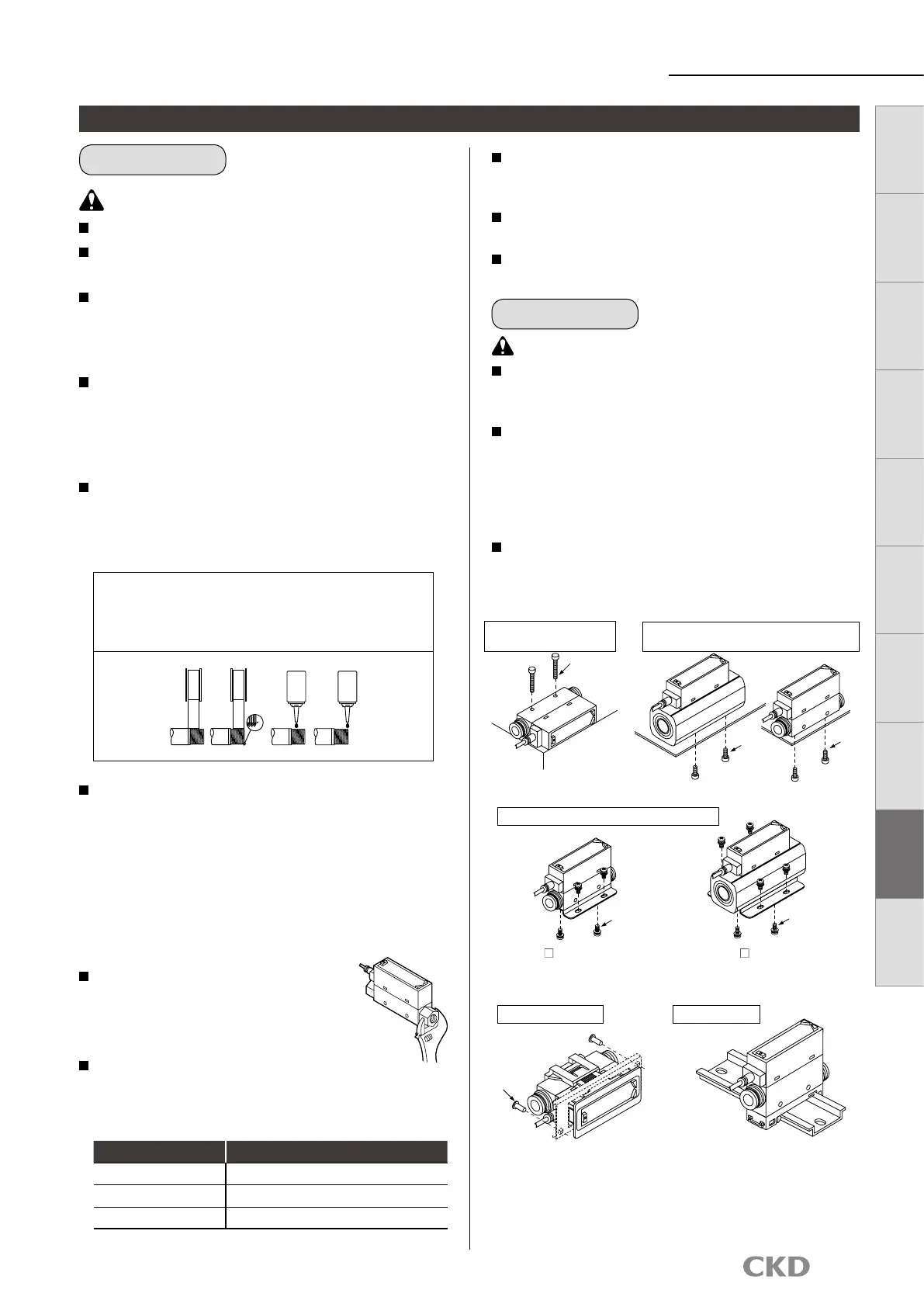

When winding uoro resin sealing tape around threads, wind

sealing tape once or twice, leaving two to three threads open at the

end of the screw. Press tape with your ngernail tip to stick it onto

threads. When using liquid sealant, leave one to two threads open

from the end, and avoid applying too much. Check that the sealant

does not get on device threads.

(Not good)(Good)(Not good)(Good)

Sealant tape

Solid/liquid sealant

Solid/

liquid

sealant

Solid/

liquid

sealant

FSM3 Series

Product-specic cautions

CAUTION

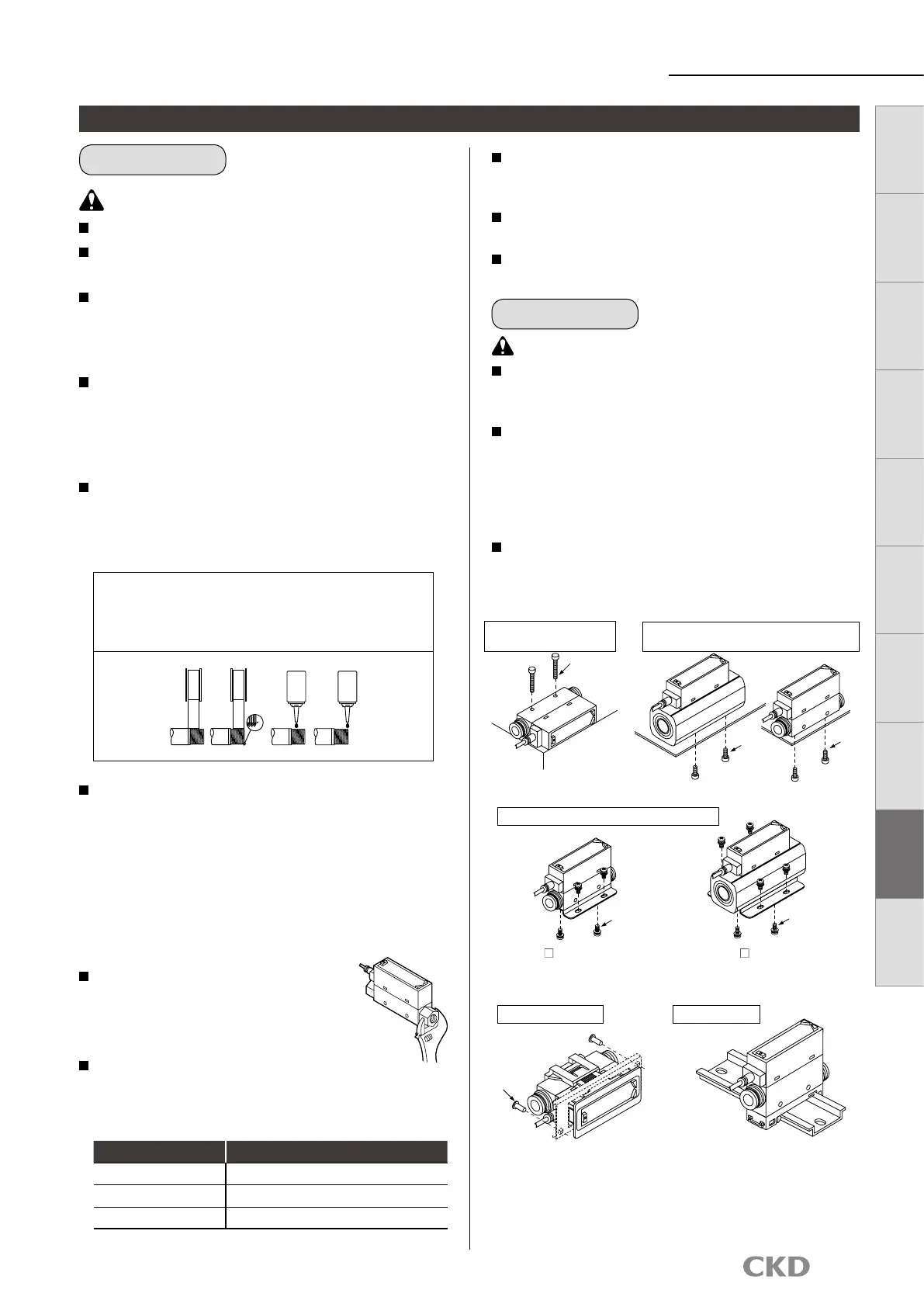

Tighten the set screw with a tightening torque of 0.06 N·m.

Complete the piping before assembly.

If the pipes are connected after assembly, excessive stress will be

applied and may damage the product parts.

When using the panel mounting method, make sure that vibration is

not applied to the product. When using on a stainless steel body, the

vibration will be amplified and could damage the product.

Lateral mounting (use of

through hole)

Vertical mounting (use of female thread on

bottom surface)

Bracket mounting (use of dedicated bracket)

Tighten the mounting screw with a tightening

torque of 0.5 N·m.

For FSM3- 005 to 201

Single bracket model No.: FSM3-B1

Tighten the mounting screw with a tightening

torque of 0.5 N·m.

For FSM3- 501 and 102

Single bracket model No.: FSM3-B2

Mounting screws

Mounting

screws

Mounting

screws

Mounting screws

Mounting screws

Mounting screws

Panel mounting DIN rail mount

46

LCD display Bar display

IO

-

Link

Internal

structure

Separate

display

Technical

data

Operating

method

Optional

products

Safety

precautions

Related

products

Loading...

Loading...