Section

6.

Planned Maintenance

Checking

the

Hydraulic

Fluid

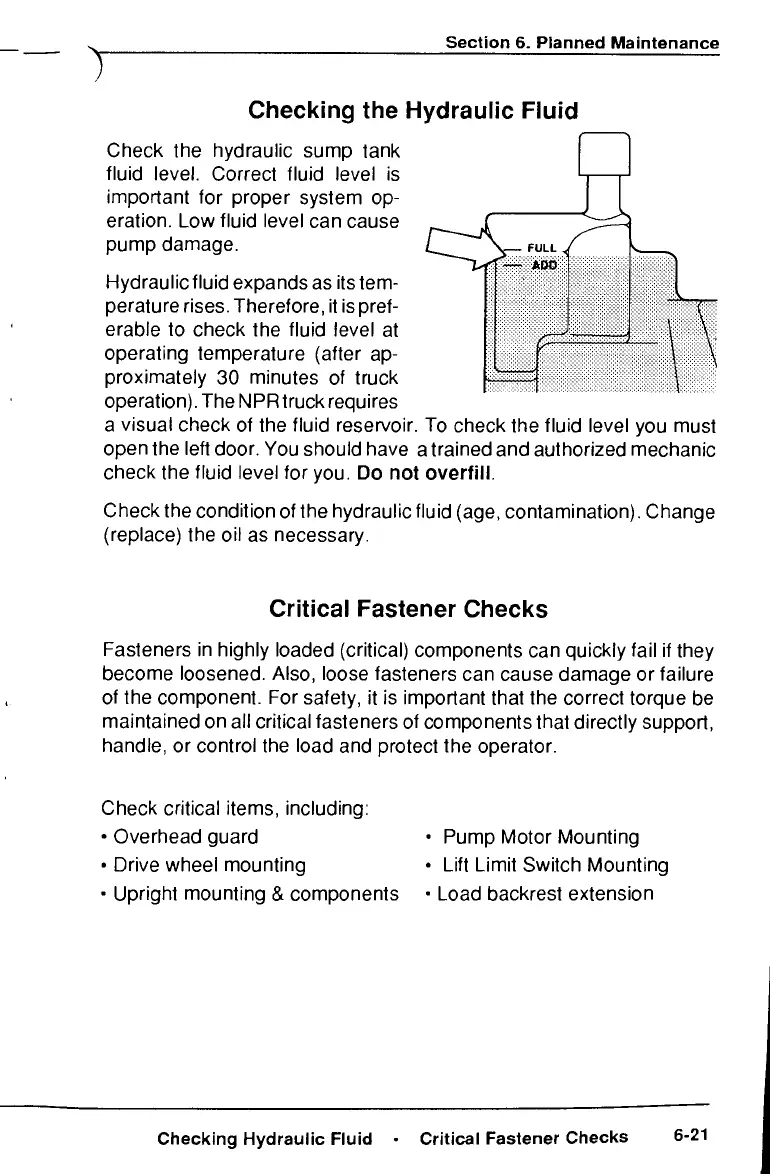

Check

the

hydraulic sump tank

fluid level. Correct fluid level

is

important

for

proper system

op-

eration.

Low

fluid level

can

cause

pump

damage.

Hydraulic fluid expands

as

its

tem-

perature rises. Therefore,

it is

pref-

erable

to

check

the

fluid level

at

operating

temperature

(after

ap-

proximately

30

minutes

of

truck

operation).

The

NPR

truck requires

a

visual check

of the

fluid reservoir.

To

check

the

fluid level

you

must

open

the

left

door.

You

should have

a

trained

and

authorized mechanic

check

the

fluid

level

for

you.

Do not

overfill.

Check

the

condition

of the

hydraulic fluid (age,

contamination).

Change

(replace)

the oil as

necessary.

Critical Fastener Checks

Fasteners

in

highly loaded (critical) components

can

quickly fail

if

they

become loosened. Also, loose fasteners

can

cause damage

or

failure

of

the

component.

For

safety,

it is

important that

the

correct torque

be

maintained

on all

critical fasteners

of

components that directly support,

handle,

or

control

the

load

and

protect

the

operator.

Check

critical items, including:

•

Overhead

guard

•

Drive wheel mounting

•

Upright mounting

&

components

Pump

Motor

Mounting

Lift

Limit Switch Mounting

Load backrest extension

Checking Hydraulic Fluid

•

Critical Fastener Checks 6-21

Loading...

Loading...