750-166 2-9

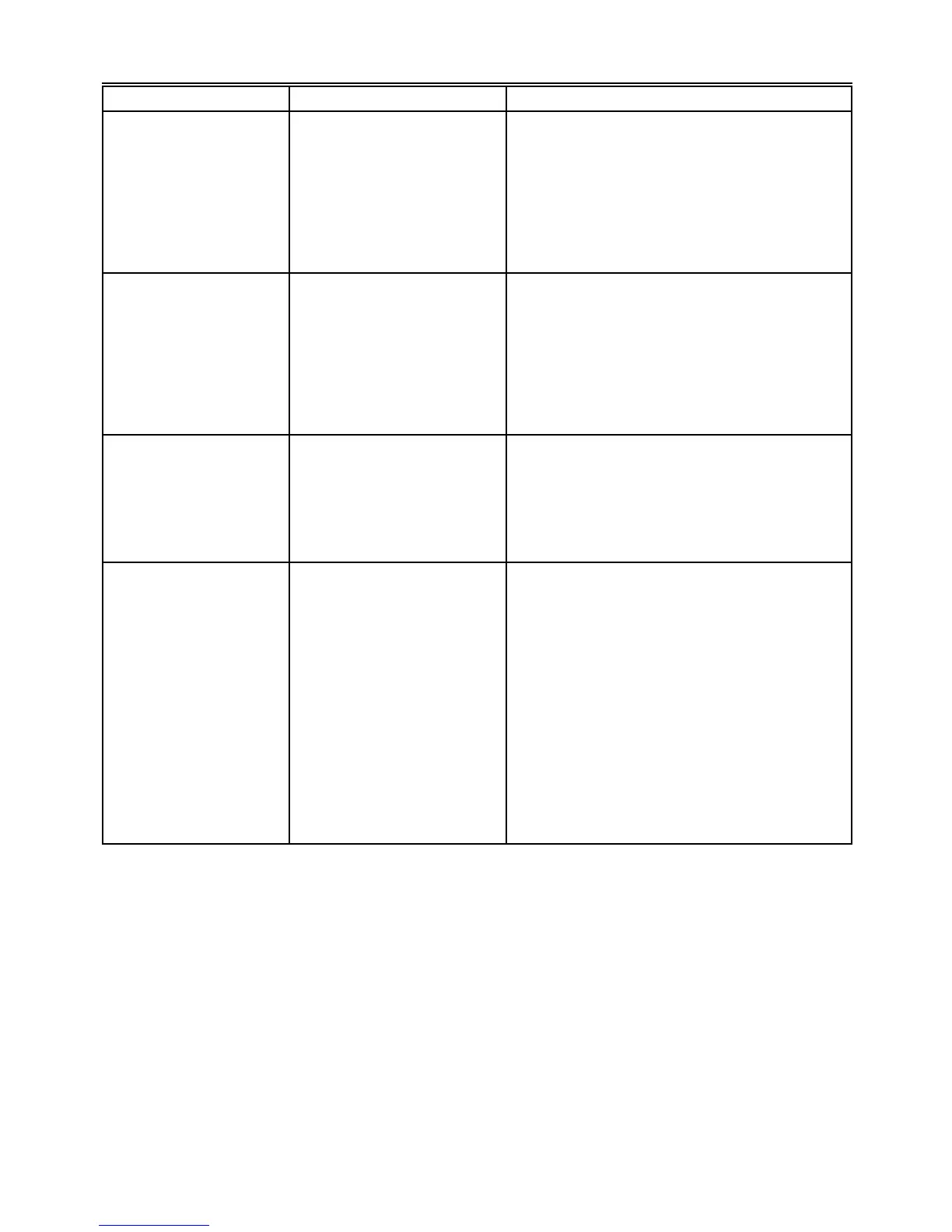

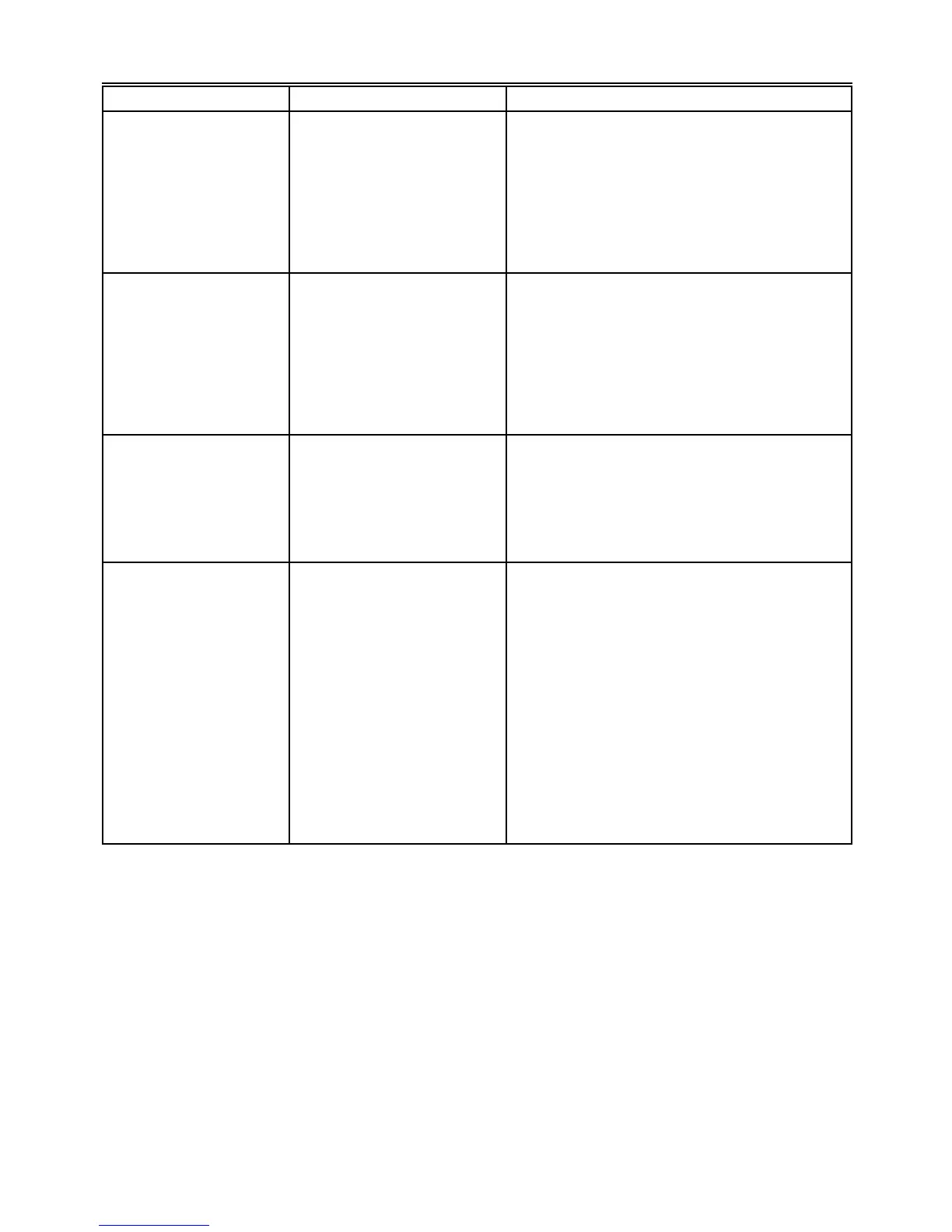

TABLE 4—FAULT MESSAGE AND RECOMMENDED TROUBLESHOOTING (Continued).

Fault Code System Failure Recommended Troubleshooting

Fault 08

*Flame Amp/Shutr*

Flame sensed when checked for

shutter-check or ampli-check

versions.

1. Check wiring; correct any errors.

2. Assure that the flame detector and flame

amplifier are compatible.

3. Remove the flame amplifier and inspect its

connections. Reseat the amplifier.

4. Reset and sequence the CB 780/CB 784.

5. If the code reappears, replace the flame amplifier

and/or the flame detector.

6. If fault persists, replace the relay module.

Fault 09

*Flame Detected*

Flame sensed when shutter open

and no flame is expected during

Standby.

1. Check that flame is not present in the combustion

chamber; correct any errors.

2. Check wiring; correct any errors.

3. Remove the flame amplifier and inspect its

connections. Reseat the amplifier.

4. Reset and sequence the CB 780/CB 784.

5. If the code reappears, replace the flame amplifier

and/or the flame detector.

6. If fault persists, replace the relay module.

Fault 10

*Preignition ILK*

Preignition interlock fault during

Standby.

1. Check wiring; correct any errors.

2. Check Preignition Interlock switches to assure

proper functioning.

3. Check fuel valve operation.

4. Reset and sequence the CB 780/CB 784; monitor

the Preignition interlock status.

5. If code persists, replace the relay module.

Fault 12

*Lockout ILK On*

Lockout Interlock powered at

improper point in sequence.

1. Check wiring to assure that the Lockout

Interlocks are connected properly between

terminals 6 and 7. Correct any errors.

2. Reset and sequence the CB 780/CB 784.

3. If the fault persists, measure the voltage between

terminals 6 and G (ground), then terminal 7 and

G (ground). If there is 120 Vac at terminal 6

when the controller is off, the Controller switch

may be bad or is jumpered.

4. If steps 1 through 3 are correct and there is

120 Vac at terminal 7 while the controller is

closed and the fault persists, check for a welded

or jumpered Running Interlock, Lockout

Interlock or Airflow switch. Correct any errors.

5. If steps 1 through 4 are correct and the fault

persists, replace the relay module.

(Continued)

Loading...

Loading...