CNC 6040 Router / Engraver System

CNCDIY CNC Routing Machines System User’s Manual

44

Step 5 Start running with tooling

Install a miller tool in the spindle and the chuck should have a distance between the chunk and

the surface of the workpiece at least one cm or more. After that, locking the cutting tool with the

spindle handles.

Tooling Locating Procedures:

1. Turn on the CNC driver and turn off the spindle. Then, set the spindle back to the original

location with using manual control of the software: Adjusting the tip of the tool location at

the top of the original location with about 1mm of the distance between the tip of the tooling

and the workpiece (X and Y position must be arrived at the original location, the Z position

should have at least 1mm distance between the tooling tip and the original position). Be

carefully the distance between the tip of the tooling and the workpiece to avoid breaking the

tooling due to insufficient space.

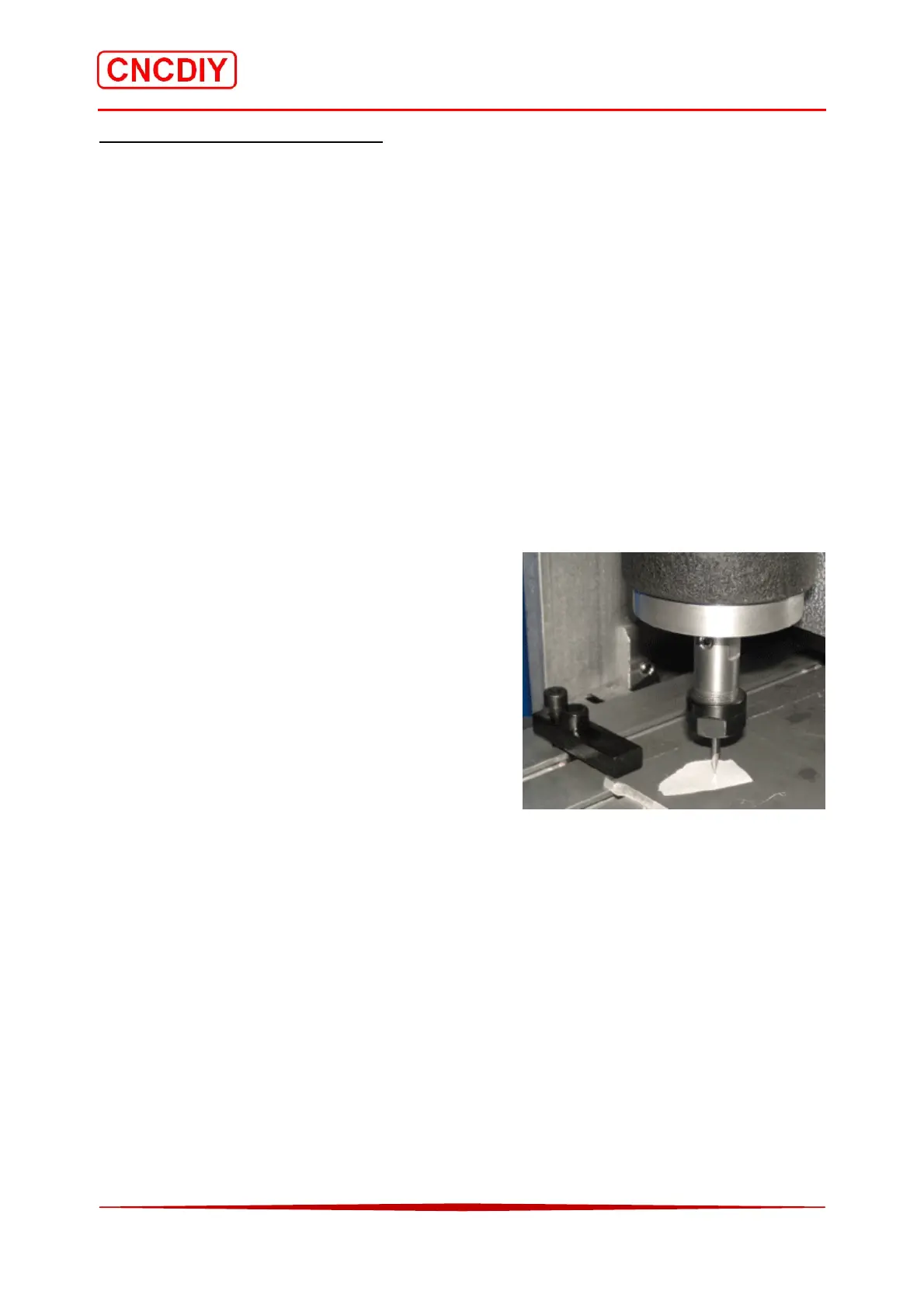

2. Turn off both CNC driver and spindle. Place a thin

paper on the original position. You can use the

knob on the top of the Z axis stepping motor to

adjust the distance between the tooling tip and the

workpiece slowly. When the tip of the cutting tool

is approaching on the paper, move the paper to

feel that whether the paper can torn by the cutting

tool. The tooling tip must not touch and contact

the surface of the workpiece. Therefore, the

accuracy can be reduced to about 0.05mm.

3. When all axes arrived at the original location, set “Zero” for all axes in your software

interface. Turn on the CNC driver switch and make sure all stepping motor are locking the

axes.

4. Make sure that the “Spindle speed control knob" pointer in the “Safe Place" position. (Please

refer to the related CNC control box user’s manual). Then, switch on the spindle power and

adjust “Spindle speed control knob" to obtain sufficient rotating speed of the spindle. At the

first time, you can turn to the maximum spindle speed to test the spindle.

5. Please wear a protection mask and a goggle for safety reason. You can start to run the G code

now!

Loading...

Loading...