9. Service and maintenance

44

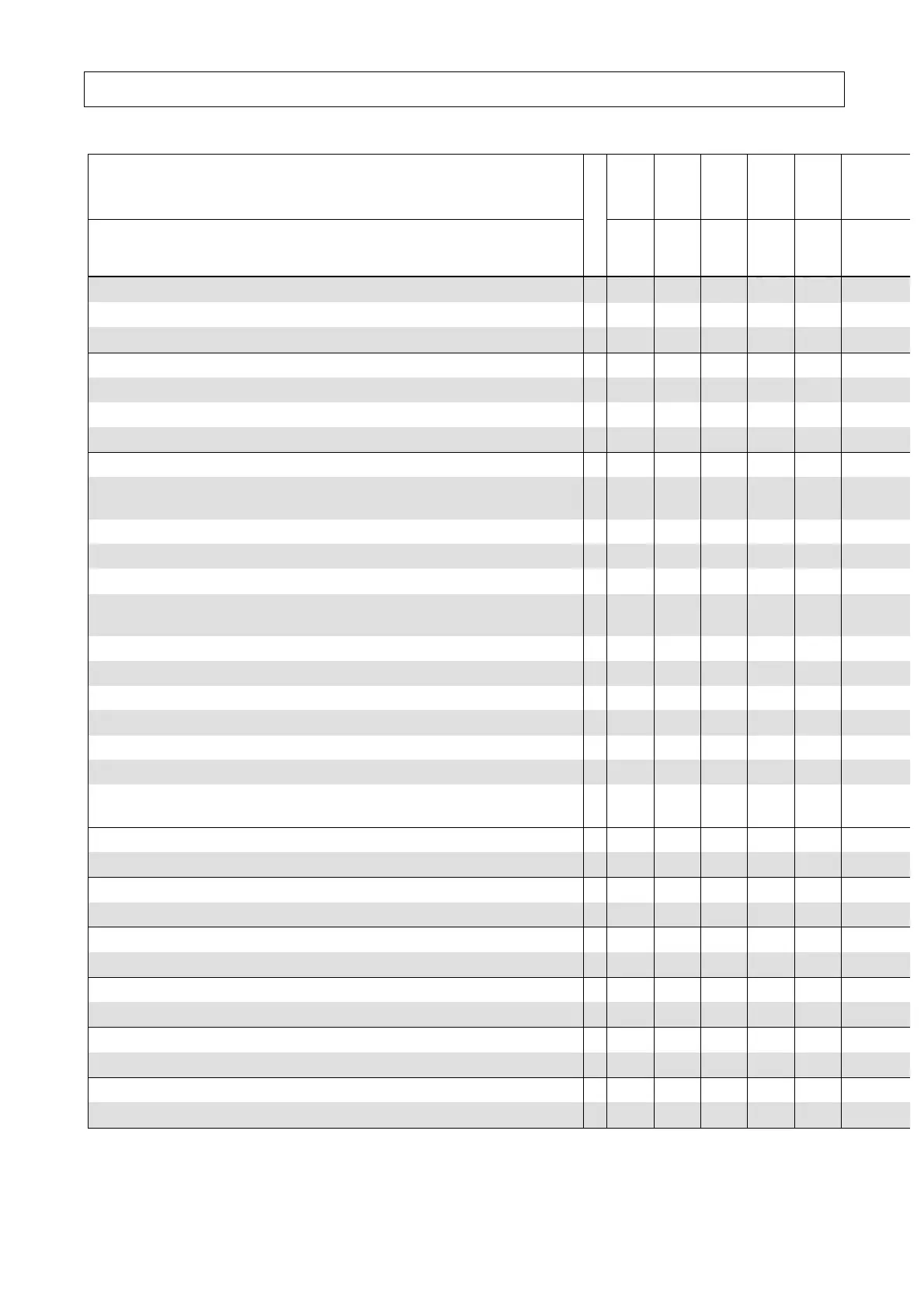

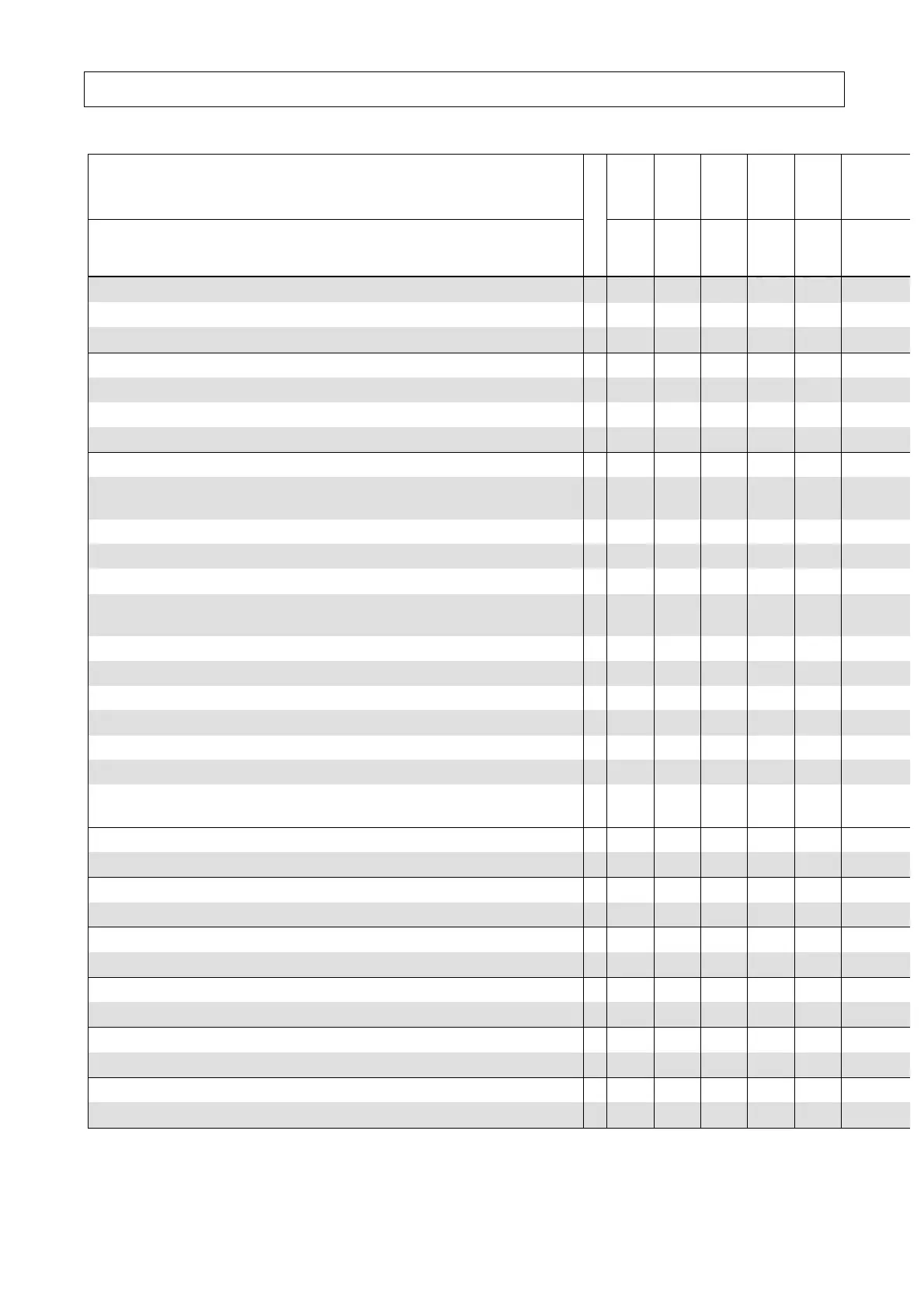

At the latest after x months

Package C Oil filter cartridge, air filter cartridge

Package D Oil separator element

Maintenance every 2000 h, although at least every 6 months:

Replacement of air filter cartridge

Replacement of oil filter cartridge

Cleaning/replacement of cooling air inlet filter

Maintenance every 4000 h, although at least each year:

Checking/tightening of connecting terminals in the switch cabinet/ and

checking of the “control transformer” setting

Checking/tightening screw connections

General maintenance/cleaning

Oil change when using CompAir - 4000 hours oil (only European version)

Oil change when using CompLube 4000 or CompLube 4000FG Food Grade

(only USA version)

Oil change when using CSS20 Food Grade oil (only Canadian version)

Oil analysis when using CS6000XL, CompLube 8000 or CompLube 8000H1 oil

Replacement of oil fine separator cartridge

Safety valve / functional test at least once a year

Replacement of lubrication cartridges

L90RS-L132RS only: Replacement of control-cabinet cooling air filter mat

Lxx W – water-cooled units only: Cleaning of dirt interceptor (In the case of

dirty cooling-water, the cleaning intervals have to be shortened as required)

Maintenance every 6000 h, although at least every 18 months:

Oil change when using CS6000XL oil (only Canadian version)

Maintenance every 8000 h, although at least every 2nd year:

Oil change when using CompLube 8000 oil (only USA version)

Maintenance every 12000 h, although at least every 3rd year:

Oil change when using CompLube 8000H1 oil (only USA version)

Inspection every 4 years:

Inspection of the electrical installation by a qualified electrician

Inspection every 5 years:

Internal inspection of the pressure vessel by a qualified person

Inspection every 10 years:

Strength test of the pressure vessel by the appointed body

These maintenance intervals must be observed!

x For your own benefit, put a cross on the servicing schedule against maintenance work when performed.

Loading...

Loading...