UGH025-0504 Thermolator TW Series

INSTALLATION 3-3

The Thermolator is easy to install, if you plan the location and

prepare the area properly.

Position the Thermolator as close to the

process machine as possible.

Make sure the installation area provides:

r A three-phase power source supplying the correct

current for your Thermolator model. Check the serial tag

on the side of the electrical enclosure for the required

voltage, phase, frequency, full load amps, disconnect fuse

size and minimum wire connection size. Field wiring

should be completed by qualified personnel to the planned

location for the Thermolator. All electrical wiring should

comply with your region’s electrical codes.

r A clean, well-ventilated environment.

The room temperature should not exceed 120°F (48°C)

with 95% non-condensing humidity and should not fall

below 32°F (0°C).

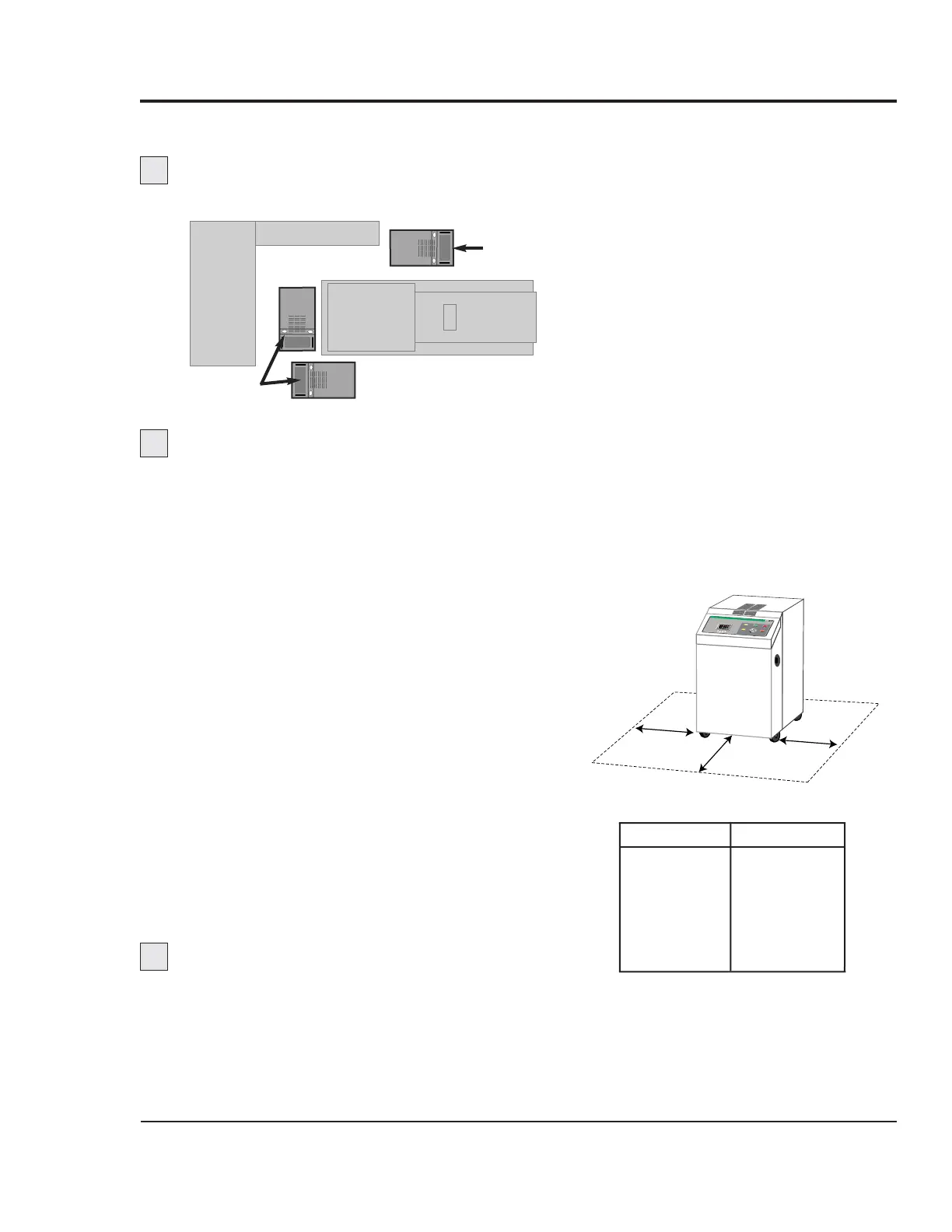

r Minimum clearance for safe operation and main-

tenance. The diagram at right shows minimum clear-

ance for operation. You also need enough clearance in

the rear for water hookups. For maintenance, you

should move the Thermolator to provide at least 36 inches

on any side of the Thermolator.

r A source of water for cooling.

City, tower or chiller water may be used. The minimum

supply pressure is 25 psi and the maximum pressure is

shown in the following chart.

Install plumbing for process and cooling lines.

You will need two 1

1

/

4

-inch NPT male fittings for the

process inlet and outlet and two 3/4-inch NPT male fit-

tings for the cooling inlet and outlet. Larger line sizes are

acceptable as long as they are reduced at the Thermolator

connections. Smaller line sizes are not recommended.

PREPARING FOR

INSTALLATION

1

Loading...

Loading...