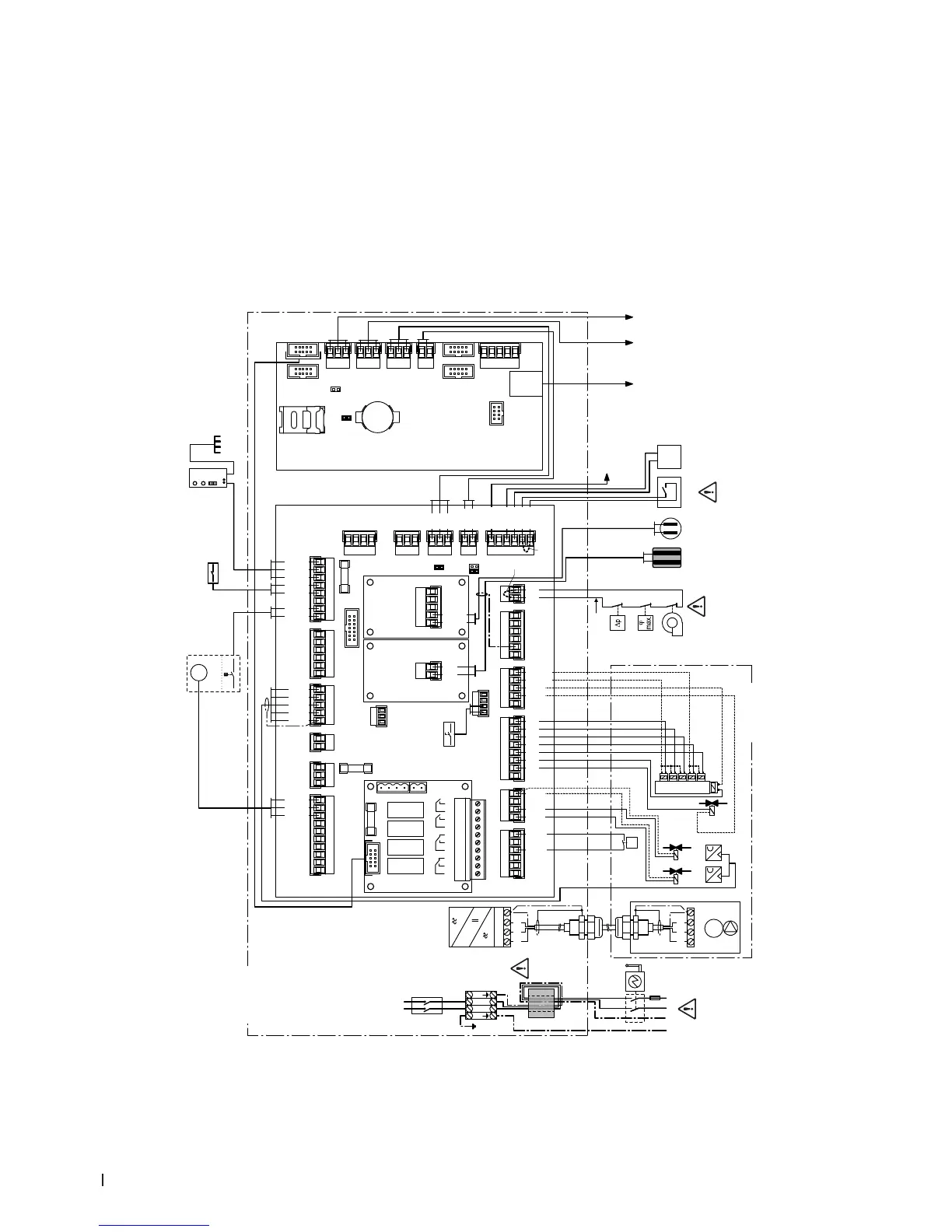

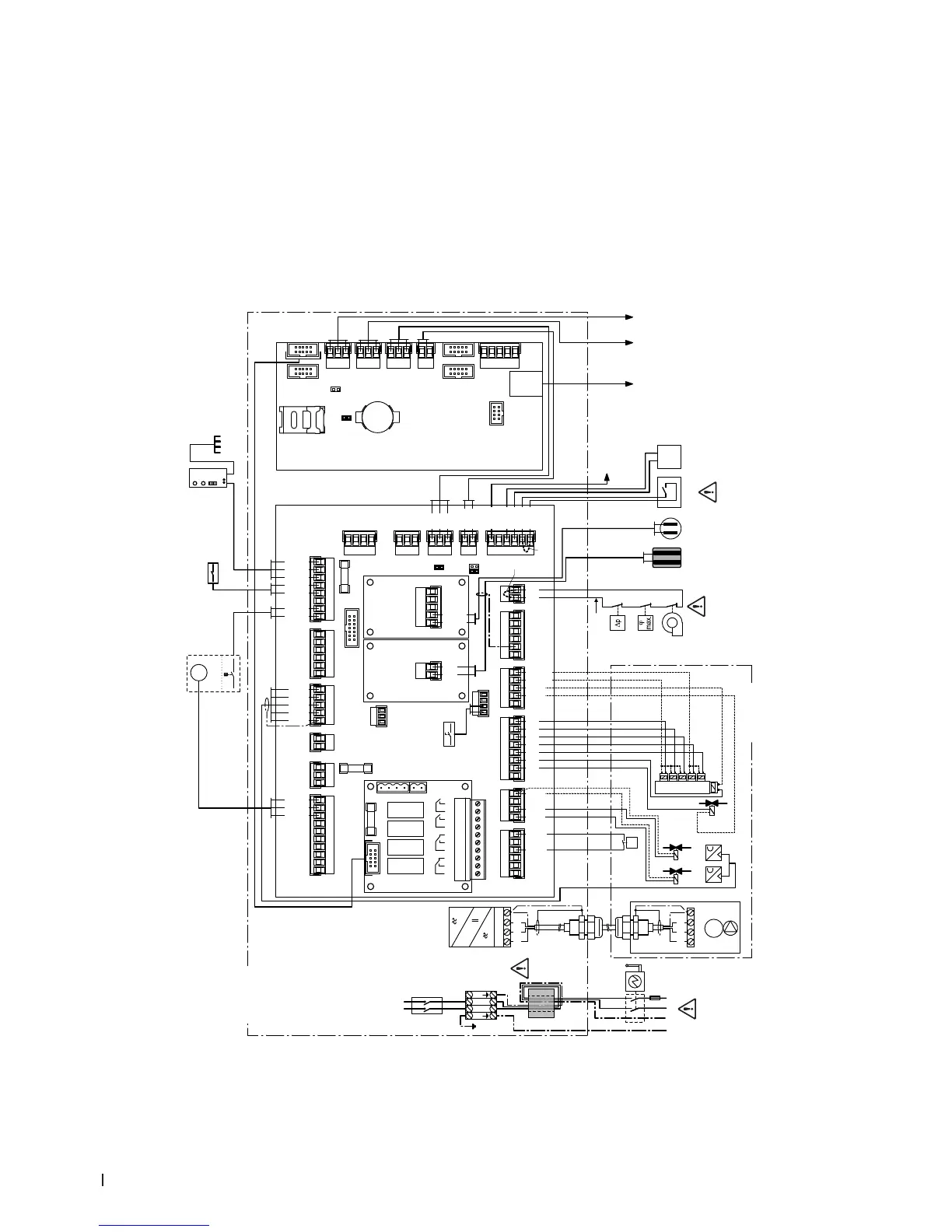

40 Installation

4.6.2 Wiring diagram Condair DL

3V

CR2032

X1X2

J1

RJ45

BAT

SD

X3X4

X19

X5X6

X7

F1 (6.3 AT) F2 (630 mAT)

X9X8 X10

X20

X11 X12

X13X14X15.1X15.2X16

J6

J10

J12

J14

J2

JP5: 10V

JP4: 24V

JP/TR

B7

K1

B6

B5

S2

PE

N/GND

L/24V P

GND

24V P

D–

GND

D+

24V E

GND

GND

24V E

24V 3

GND

GND

GND

24V 1

24V 2

SC2

SC1

A2A1

GND

+

–

GND

+

–

GND

+

–

GND

24V+

J3

H

Error

1 2 3

Service

4 5 6

Running

7 8

Unit On

9 10

+

–

Y

B4

24/10 V

TMP

GND

HUM

24V E

Enable

LinkUp

RS485

BMS

RS485

A3

B2

FQ+

24V P

EN FQ2

EN FQ1

ERR FQ

GND

24V P

5V P

GND

PS4

PS5

J14

J12

J10

J6

RJ45

Etnernet

P<

PS2

Y5

Y6

Y7

Y8

Y9

Y10

Y3

Y1

24V SCB

GND

24V P

24V P

24V SCA

Y2

Y1

Y10

Y9

Y8

Y7

Y6

Y5

PS1

PS2

PS3

LEVEL/T

GND

24V P

U1

PEWVU

321

M1

PEL3L2L1

M

3~

Z

Z

321

PS4 PS5

24V IC

GND

D–

GND

D+

AG+

AG–

Cnd W1

Cnd W2

Tmp W1

Tmp W2

GND

L

L1 N

L1 N

N

PE PE

L

N

F3

Q

SF

S3

Y4

24V P

Y11

Y4

Y3

T1 B1

K2

LS1

LS1-LS4

M2

B3

M

24V E

24V E

24V E

24V E

LEAK

CS1

LVL DP

GND

PE

PE

UV–

UV+

PE

PMP N

PMP L

PE

DOSP–

DOSP+

S1

J7

J4

X18 X17

Legend

A1 Driver board

A2 Control board (CPU) with display

A3 Ag ionisation

B1 Conductivity measuring board

B2 Conductivity sensor

B3 Level sensor disinfection pump (option)

B4 Demand or humidity signal

B5 Ventilaton interlock

B6 High limit humidistat

B7 Air proving switch

F1 Fuse 230V supply

F2 Fuse 10V / 24V supply

F3 Fuse mains supply 10AT

H Remote operating and fault indication board

J1 Cable bridge, if no external enable contact

is connected

J3 Cable bridge, if no monitoring devices are

connected to SC1 and SC2

J4 Jumper for activating the terminating resis-

tor for Modbus network (Jumper must be

connected, if Condair DL is the last unit in

the Modbus network)

J7 Jumper connected: Modbus communication

via RS 485 interface (J6)

JP4 Jumper connected = 24V on X16,

JP5 no jumper!

JP5 Jumper connected = 10V on X16,

JP4 no jumper!

JP/TR Jumper connected to last driver board

K1 External safety chain

Do not apply extraneous voltage with K1

K2 External ushing contact or start

compressed-air ushing (option)

LS1 Control leakage monitoring

LS2-4 Floor sensors for leakage monitoring,

max. 3

M1 Booster pump (Type A only)

M2 Disinfection pump (option)

PS2 Pressure switch (option sterile lter)

PS4 Pressure sensor inlet pressure

PS5 Pressure sensor nozzle pressure

Q Electrical isolator (supplied)

S1 <Humidication On/Off> switch (located on

the front cover of the control unit)

S2 External enable contact humidication

S3 <Control unit On/Off> switch (located on the

bottom plate of the control unit)

SF Snap ferrite for mains supply, lead wires

twice through bore of snap ferrrite

T1 Control board Ag ionisation

U1 Frequency converter (Type A only)

Y1 Safety valve inlet

Y3 Compressed-air ushing valve for

compressed-air ushing (option)

Y4 External water supply ushing valve (option)

Y5-9 Spray valves

Y10 Drain valve

Z ESD cable glands, Expose cable shield here

Control unit

Driver

board

Control

board

Snap ferrite:

Lead wires

twice through

bore of

snap ferrite

High leakage current!

Connect 2x protective

earthing conductor

Do not apply extrane-

ous voltage via K1!

Do not apply extrane-

ous voltage via S2!

Analogue control

or sensor signal

External

voltage supply

10V/24V max. 300 mA

(JP4=24V, JP5= 10V)

Central unit

Abb. 24: Wiring diagram Condair DL

Loading...

Loading...