42 Installation

4.6.3.2 Installation work central unit - control unit

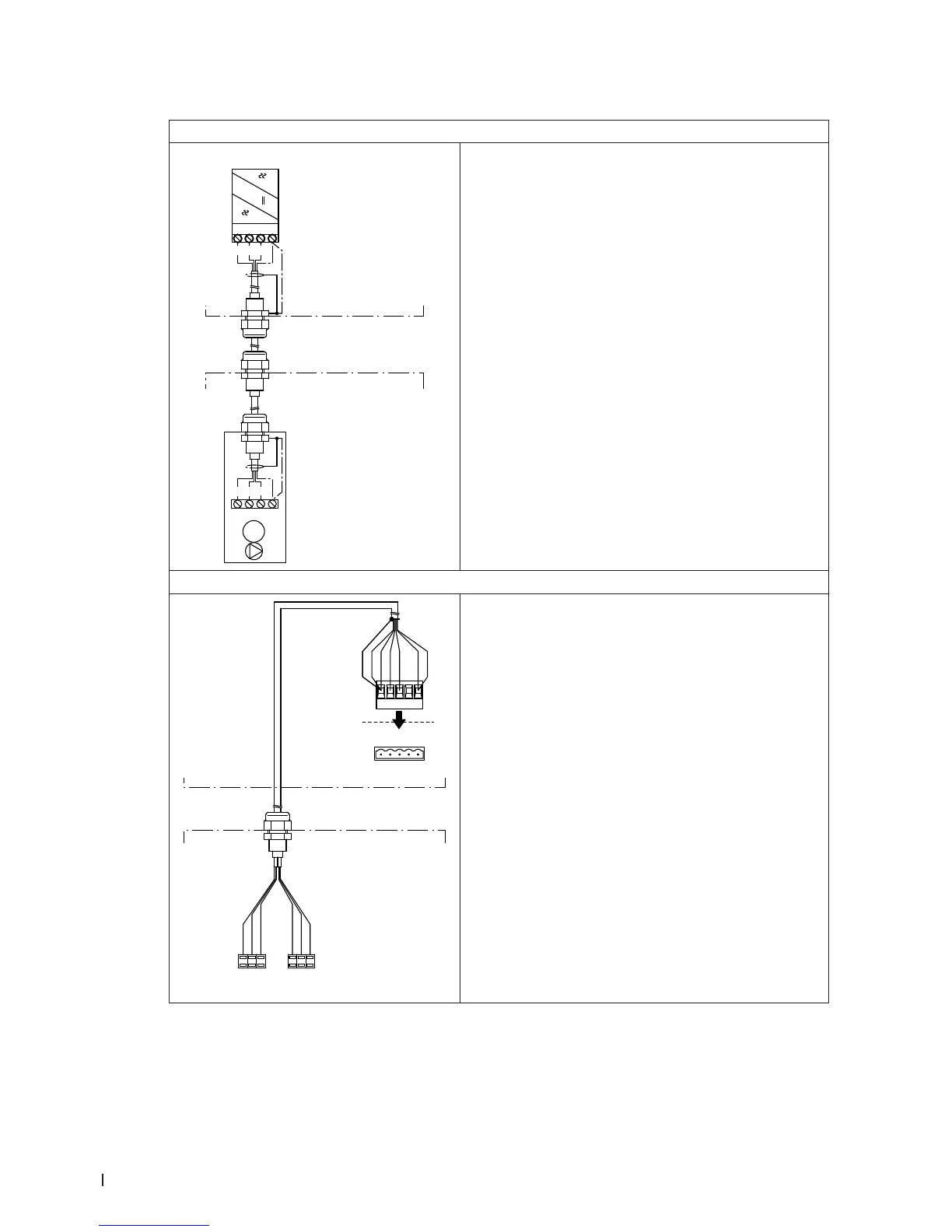

Connecting the motor cable (MC) to the frequency converter (type A only)

U1

PEWVU

321

M1

MC

PEL3L2L1

M

3~

Z

Z

321

Control unit

Central unit

Ex factory the motor cable is connected to the frequency

converter inside control unit. On site the motor cable

must be fed via the cable gland (top left) into the central

unit, and there be connected to the booster pump motor

according to the wiring diagram. At the section where

the motor cable passes through the metallic EMV cable

gland (Z), the cable shield must be exposed to achieve

electrical connection of the cable shield with the EMV

cable gland.

Note: the remaining cable between control and central

unit must be pulled down into the central unit and there

be inserted in a loop into the corresponding cable duct.

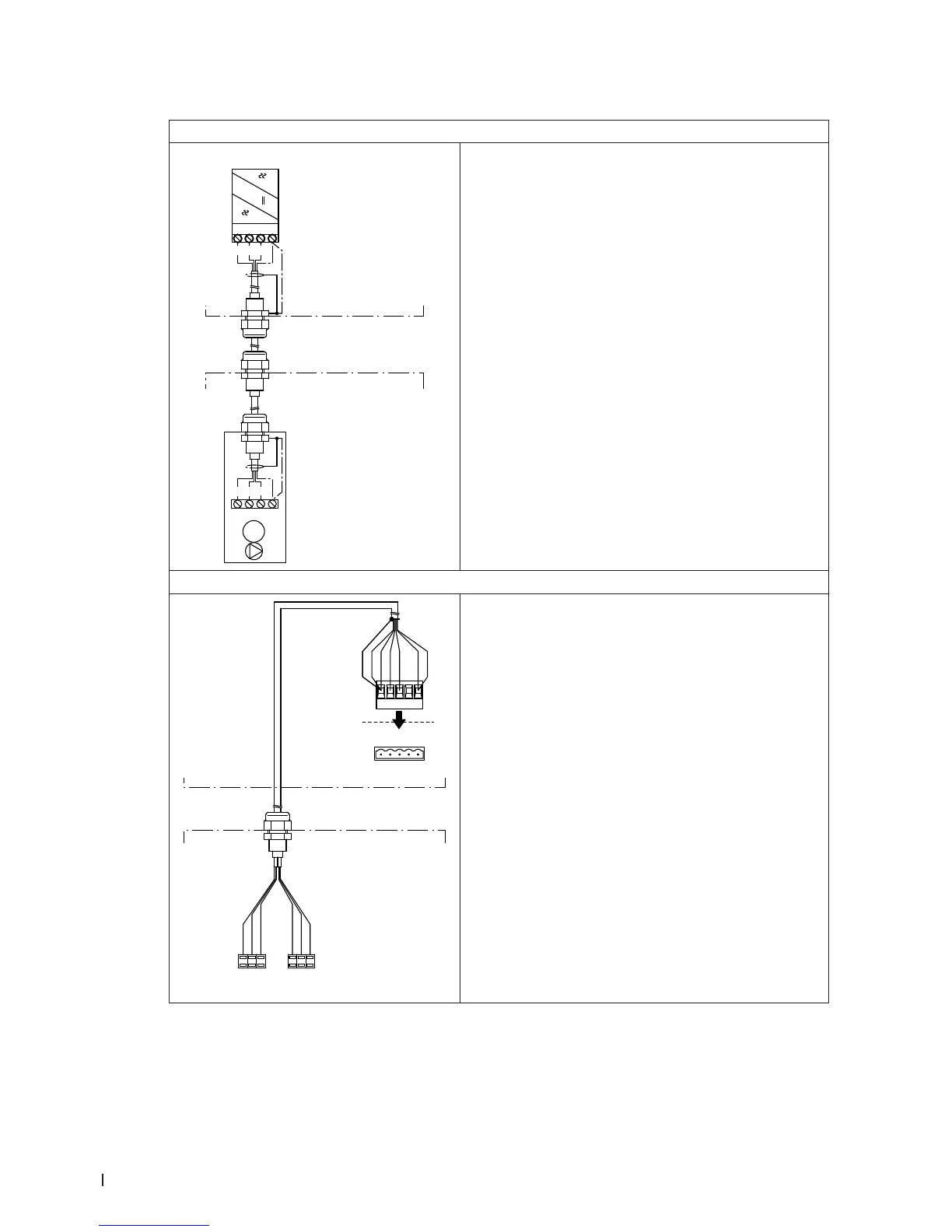

Connecting the cable harness “Pressure sensors” (CH1)

grau

weiss

pink

grün

braun

gelb

PS4

PS5

analog

analog

+

-

-

+

CH1

grau

weiss

pink

gelb

grün

braun

X10

24V P

5V P

GND

PS4

PS5

X10

Control unit

Central unit

Ex factory the cable harness “Pressure sensors” (CH1) is

connected inside central unit to the corresponding pres-

sure sensors. On site the terminal connector of the cable

harness must be connected to the appropriate terminal

(X10) on the driver board inside the control unit.

The cable harness is to be led through the rectangular

cable feed through into the control unit

Note: lead cable harness inside the control unit in the

cable ducts to the corresponding terminal on the driver

board. The remaining cable of the cable harness be-

tween control and central unit must be pulled down into

the central unit and there be inserted in a loop into the

corresponding cable duct.

Loading...

Loading...