Operating Manual PG11 / PGE11 Page 17

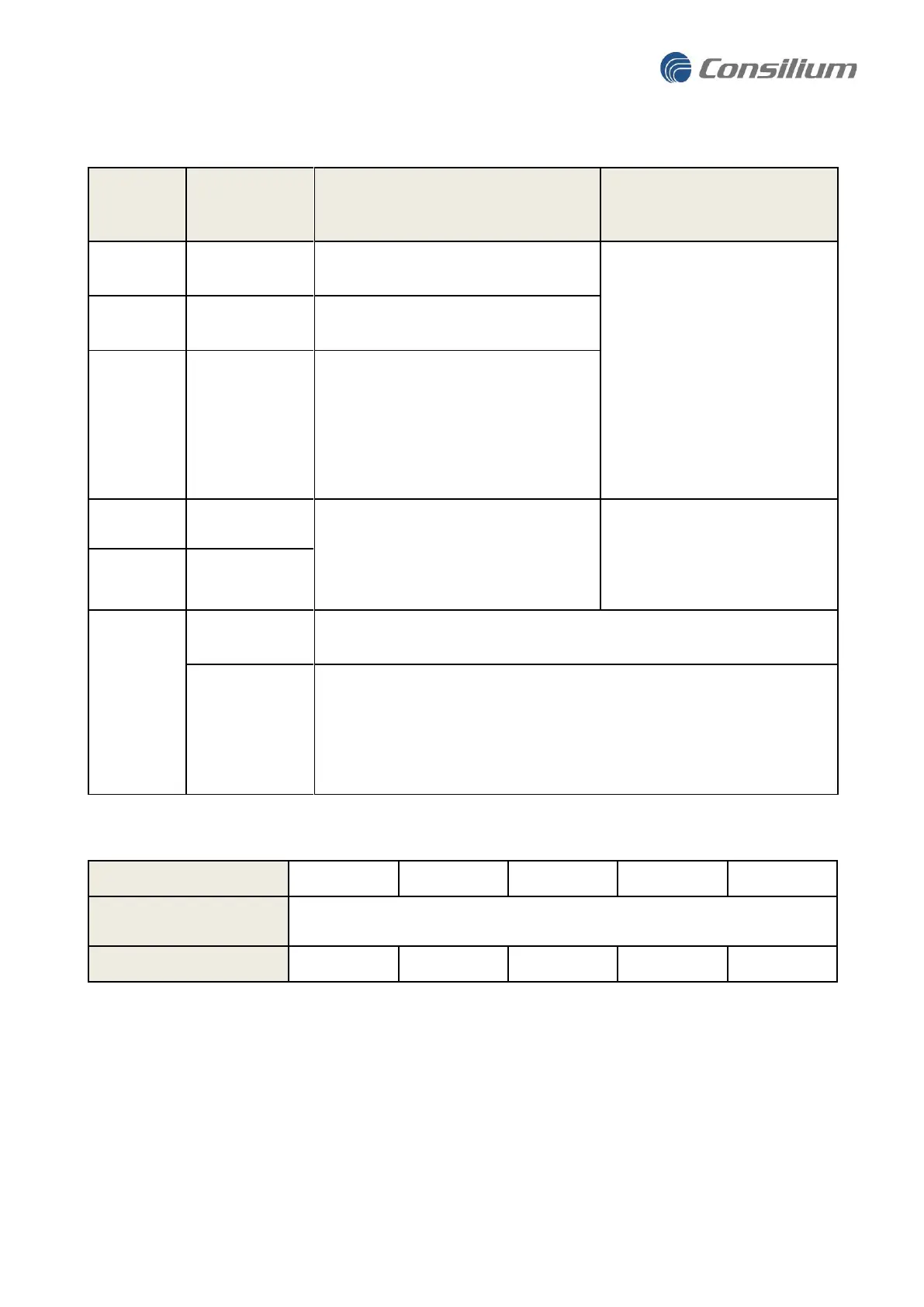

Table 1. Specifications of terminals.

Terminal

(detector

wire color)

Power, Positive

supply voltage

According to site requirements

and Table 2. Min. cross section:

0.14mm²

Max. cross section:

2.5mm² (Stranded)

4mm² (Solid)

Power, Supply

voltage return

Analog 0 - 20 mA DC signal overlayed

with a HART signal. Signals levels

described in

table 4

. The HART signal

is not interfering with the analog DC

signal and is described in a separate

chapter.

Maximum impedance 500

Ω

.

Two wires for connection to digital RS-

485 serial communication, Modbus

RTU.

Industrial communication cable

with shielded twisted pair.

Min/max cross section 0.14/2.5

mm² (stranded) or max 4 mm²

(Solid)

External grounding shall be used when the detector is installed in an Ex-

zone.

Normally not used. Shield of the cable is typically connected to instrument

earth in the central control cabinet and is normally not terminated at the

detector.

If extra RFI protection is required, and the installation's grounding

principles/regulations allow it, the shield can be terminated to local ground

via the internal earth point at the detector.

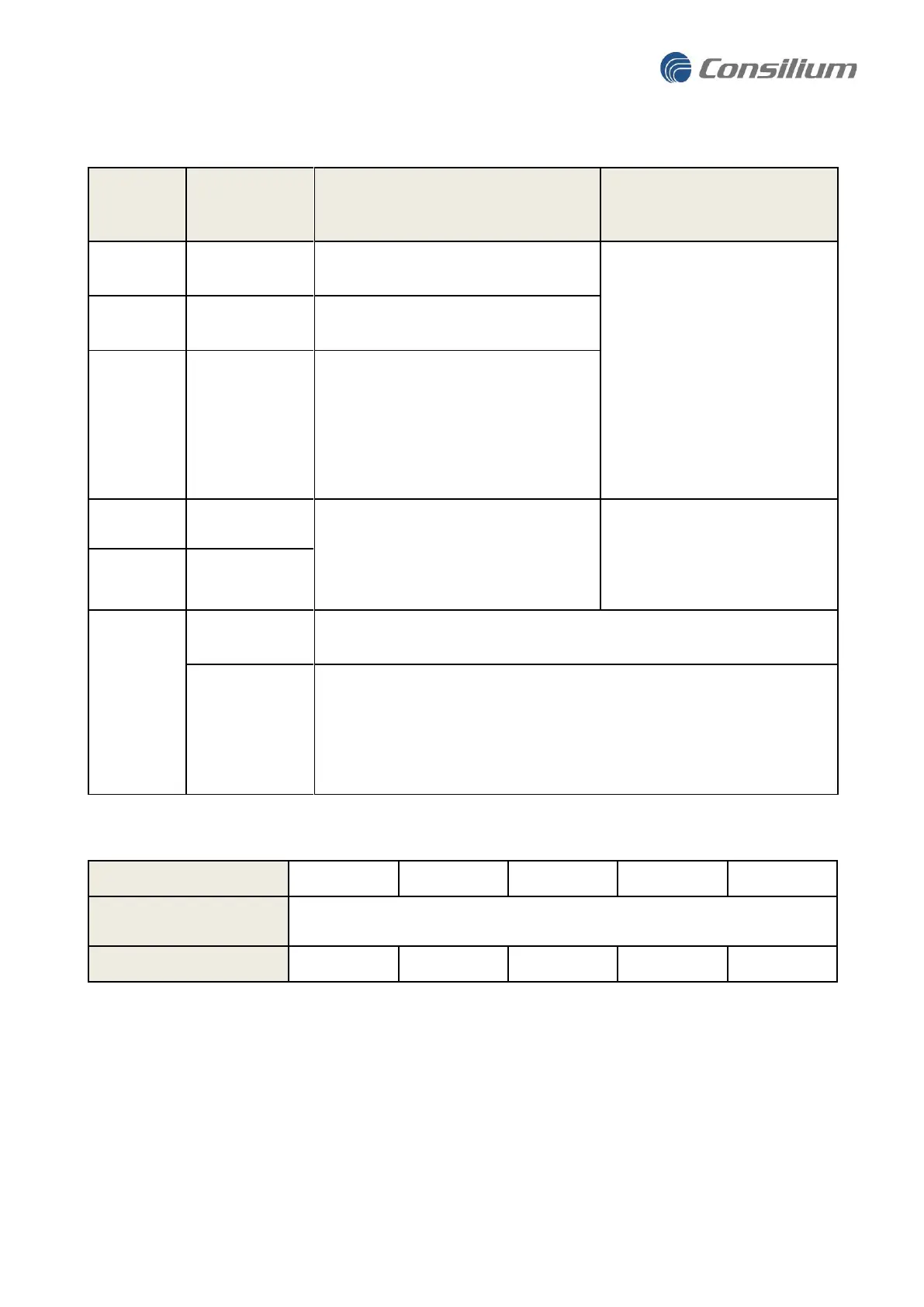

Table 2. Minimum voltage to PG11 shall be 18 VDC. Examples of cable and maximum length.

* For a nominal power of 24 V. Longer cable can be used with higher supply voltage.

3.4.1 Booting up the Gas Detector

When turning on the power to the Gas Detector it has a boot-up time of 60 seconds. During this time the

Detector will run self diagnostics and if the indicator is configured to be active it will show yellow light. After

this boot-up time the Detector is ready to detect gas, but for a very precise testing of gas accuracy the

Detector should be allowed for another 20 minutes warm up time

Loading...

Loading...