Operating Manual PG11 / PGE11 Page 38

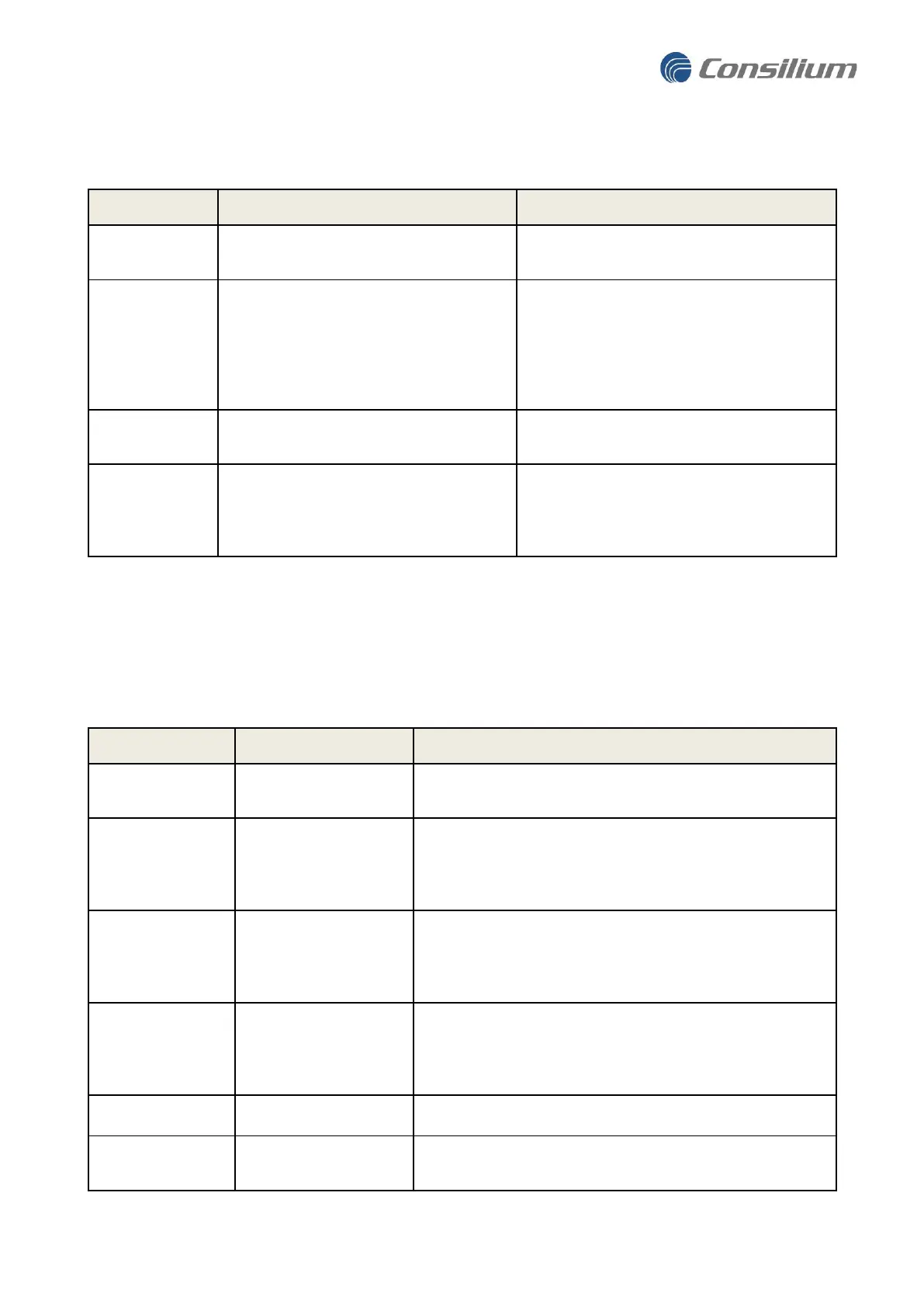

Table 5. Overview of possible issues and suggestions for solutions. Error codes can be found through the

HART or MODBUS interfaces. Please consult the corresponding chapter for instructions.

Unstable detector reading

Verify that the detector has sufficient local

Earthing.

Too low gas reading when exposed to

test gas

● Weather conditions not taken into

consideration (wind and ambient

pressure has impact)

● Too low flow of test gas

● Too short test time to let test gas reach

detector and fill test area

Fault reading in

control room

Detector passed troubleshooting

Frequent cleaning of optics required.

Check that the detector has been mounted

in correct orientation as stated in the

Manual. If it is mounted vertically dust and

water will accumulate on the optics.

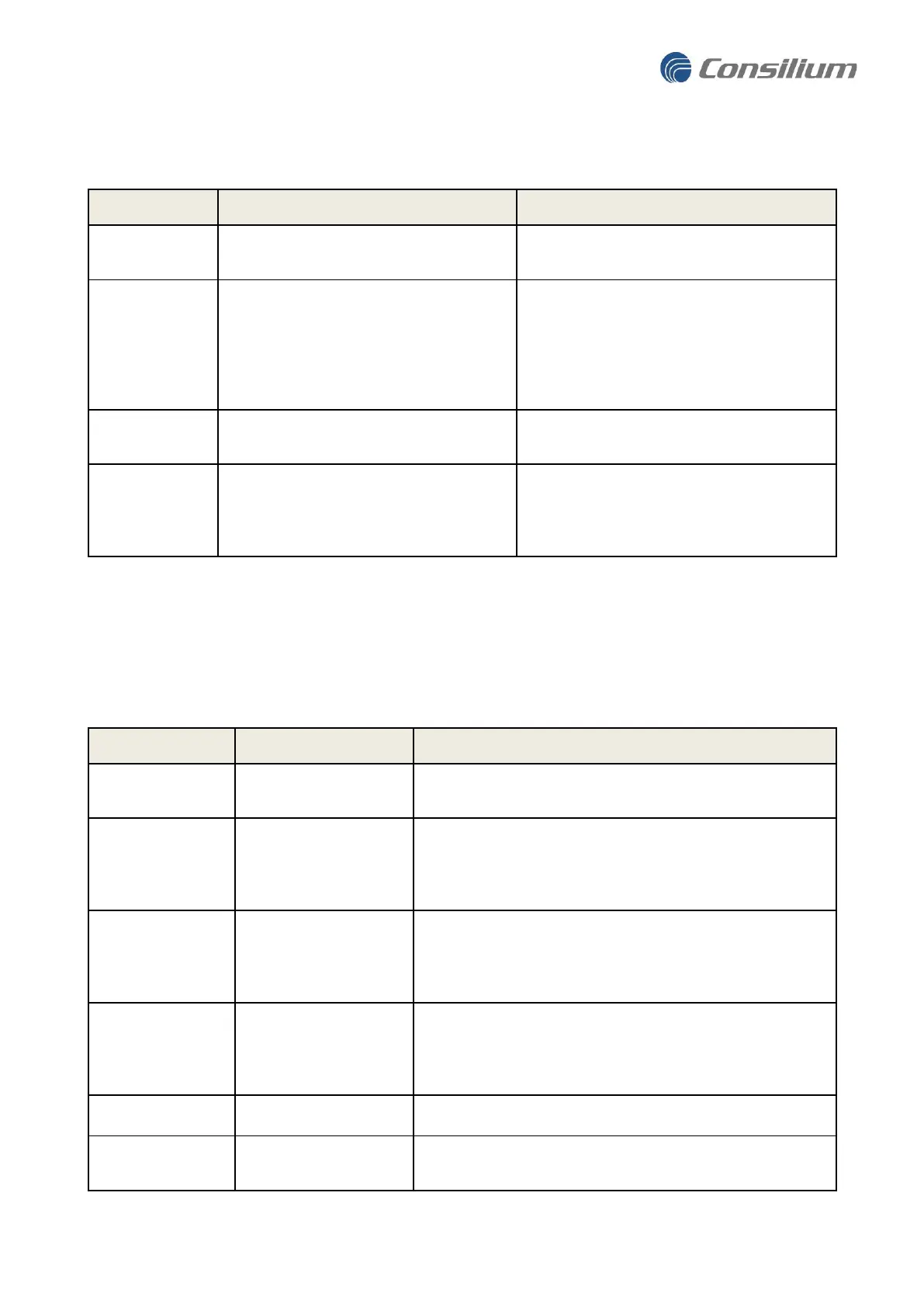

11 Accessories and Spare Parts

Below is an overview of accessories and spare parts for the PG11. Use the ordering number to refer to these

parts when in contact with the Supplier.

Mesh fitted over the measuring section of the detector to

keep insects from blocking the Optics.

To perform a quick gas test of the Safety Function of the

PG11 detector. Small container with gas connection that is

fitted on the outside of the detector nose, and removed

after the “Bump test” is finished.

To perform a quick gas test of the Safety Function of the

PGE11 15 cm detector. Small container with gas

connection that is fitted on the outside of the detector

nose, and removed after the “Bump test” is finished.

PGE11 Medium Gas

Test kit

To perform a quick gas test of the Safety Function of the

PGE11 35 cm detector. Small container with gas

connection that is fitted on the outside of the detector

nose, and removed after the “Bump test” is finished.

For easier cleaning of the optics.

Enables detectors to be mounted in already existing

mounting screws. Simplifying replacing other products.

Loading...

Loading...