Making a zero-clearance fence

1. DISCONNECT THE MACHINE

FROM POWER!

2. Remove the infeed and

outfeed fences from the fence base.

3. Select a piece of straight,

smooth stock that is the same height

and thickness as the infeed/outfeed

fences and approximately 36” in

length.

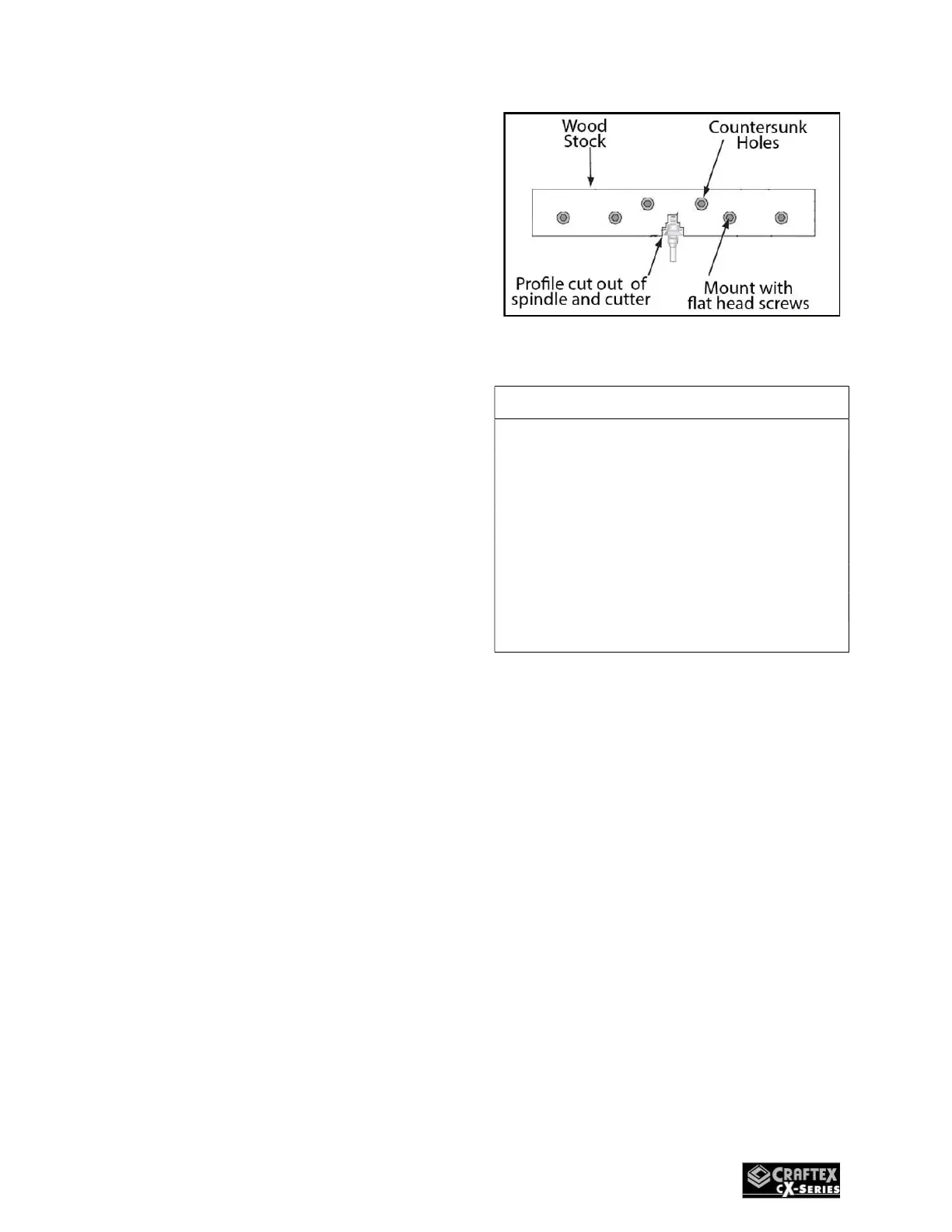

4. Cut the outline of the spindle

and router bit from the center of the

stock in Step 3, as shown in (FIG.54)

Note: Make the outline as close as

possible to the router bit and spindle

without interfering with rotation.

5. Create countersunk mounting

holes in the zero clearance fence

board (Fig.54) to secure the new

fence and router bit guard to the

base.

Figure 54

CAUTION!

ALWAYS use hold downs or

featherboards and push sticks when

shaping small or narrow stock. These

devices keep your hands away from

the spinning router bit and

sufficiently support stock to allow a

safe and effective cut, reducing the

risk of personal injury.

6. Secure the zero-clearance

fence board & router bit guard to the

fence base, then ensure the fence is

parallel with the table T-slot.

7. Check for proper clearance,

reconnect the router to the power

source and make a test cut to verify

the results.

Free-Hand Routing

Free hand routing, done without the

protection or aid of the fence &

Loading...

Loading...