9

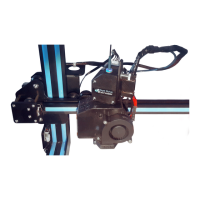

Install X-axis Passive Block

• Snap the brass sleeve on the left side of the X-axis timing belt into the extruder

back support plate.

• Attach the X-axis passive block to the X-axis profile.

Note: Be cautious not to screw it down, ensuring the X-axis passive block can slide along

the X-axis profile.)

• After looping the X-axis timing belt around the X-axis passive block, snap the

brass sleeve at its right end into the extruder back support plate.

• Push the X-axis passive block to the right to tension the X-axis timing belt to the

same state as the Y-axis timing belt, then tighten the set screw on the X-axis

passive block.

Note: Push to the right and tighten the retaining screws.

Install the X-axis Kit and Adjust Tightness

• Fit the X-axis kit into the Z-axis profile, aligning the V-wheels on the left and right

sides with the slot in the profile and ensuring the T-rod nut is aligned with the T-

rod.

Note: Adjust the eccentric spacers on the left and right if the passive blocks on both

sides cannot fit in.

Install the Top Gantry Profile and Profile Cover

• Secure the top gantry profile to the upper end of the gantry using four M5×25

screws.

• Attach the profile covers to the ends of the top gantry profile.

• Tighten the two retaining screws on the Z-axis passive block.

Install the Material Rack and Barrel

• Assemble the material rack and barrel.

• Thread the two M5×8 screws through the material rack and then screw on the M5

T-nuts.

Note: There is no need to fully tighten it.

• Finally, secure these components to the top gantry profile.

Loading...

Loading...