Cuda 2412 • 8.914-384.0 • Rev. 5/12

11

AUTOMATIC PARTS WASHER

OPERATOR’S MANUAL

SECTION 3: OPERATION

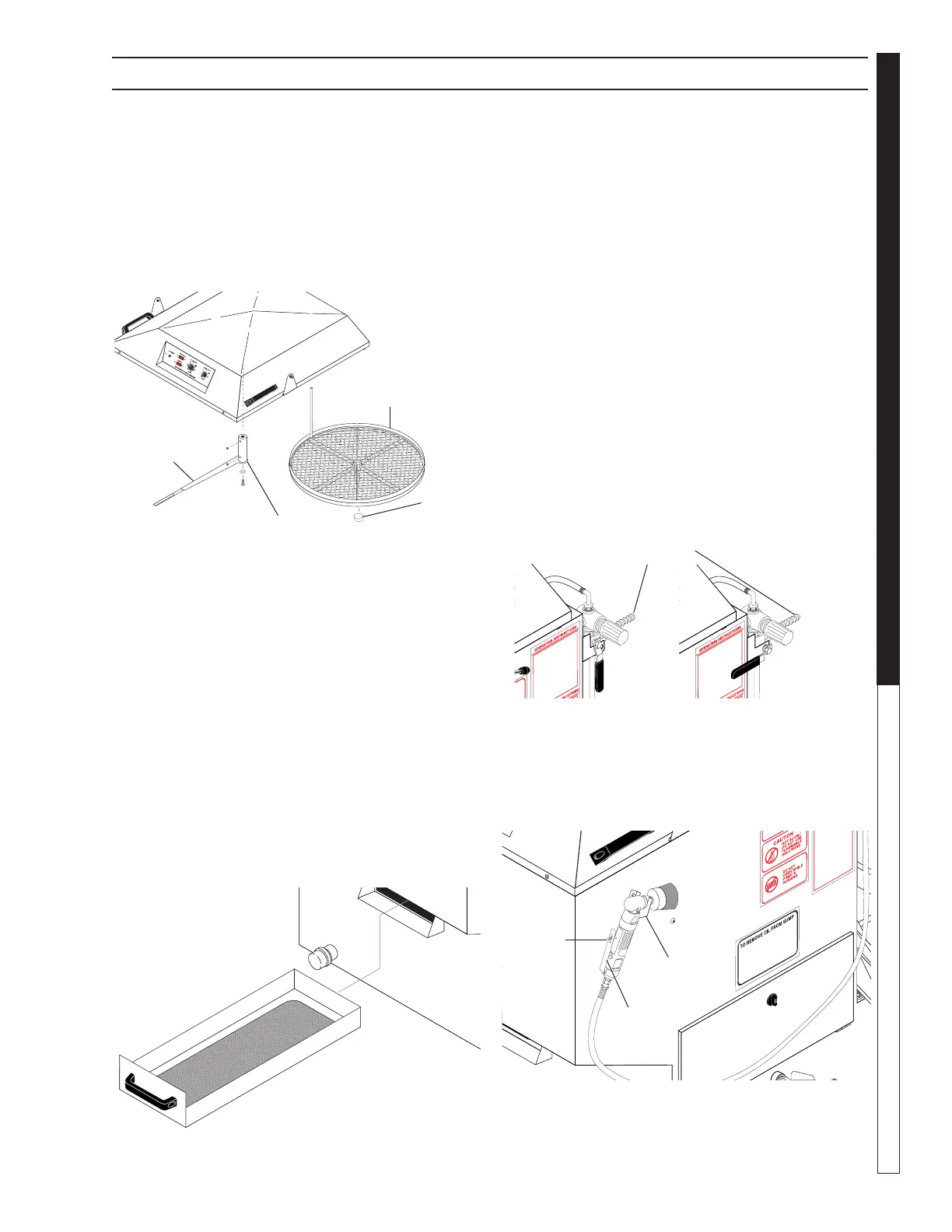

Turntable Assembly

The turntable assembly uses a torque arm mounted

on the underside of the lid to rotate the turntable (See

Figure Below). The torque arm includes a torque limiter

which prevents the turntable motor from burning out in

case a part falls off the turntable and obstructs rotation.

For information on adjusting the torque limiter, refer

to Torque Limiter. For information on replacing the

turntable motor, refer to Turntable Motor.

Removing the Turntable

To remove the turntable, grasp it evenly on opposite

sides and lift it free of the spindle.

Important: The turntable rotates on a thrust bearing

inside of the hub. As you lift the turntable free of the

spindle, take care not to jar the thrust bearing loose.

If the thrust bearing drops out of the hub, inspect it for

wear then either replace it or re-install it (See Previous

Figure).

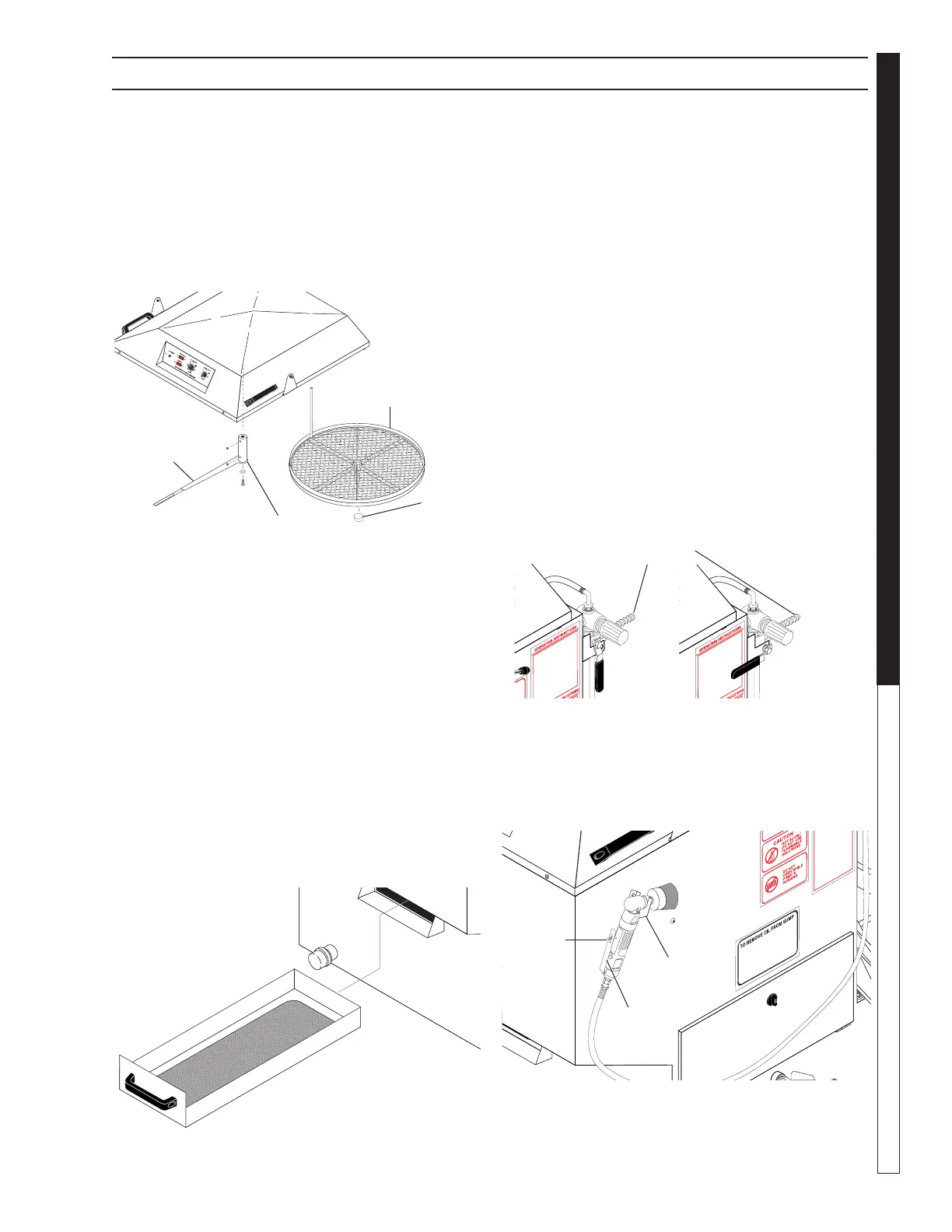

Debris Screen

The debris screen is located below the turntable inside

of the wash chamber (See Figure Below). The debris

screen continuously filters debris particles from the

cleaning solution to ensure blockage free spray nozzle

operation, and also provides a safeguard against small

parts that might accidentally be washed through from

the wash chamber.

The frequency at which you must clean the debris

screen depends on machine usage. In general, you

should clean the screen before operating the machine

each day. To access and remove the screen you must

remove the turntable (see Removing the Turntable).

NOTE: Never operate the machine without the debris

screen in place. The screen is specially sized to filter

particles that could clog the spray nozzles or damage

the water pump. Operating the machine without the

debris screen in place could cause spray nozzle

clogging or water pump failure.

Air Flow Valve (Optional)

The air flow valve is located on the right rear corner of

the machine. It is a three-way ball valve that controls

the flow of compressed air to the power brush and the

hand detail brush (See Figure Below).

Power Brush (Optional)

The power brush is located on the right front corner of

the machine (See Figure Below). Refer to Connect a

Compressed-Air Line and Accessories for detailed

installation information.

NOTE: The power brush is available as an option on

this machine. For ordering information, contact your

distributor or call customer service.

Throttle

Lever Lock

Throttle

Lever

Holding

Bracket

Position #2 For

Power Brush

Position #1 For

Detail Brush

Compressed

Air In

Thrust

Bearing

Turntable

Turntable Drive

Bar

Torque Limiter

Loading...

Loading...