14

medium such as engine exhaust, furnace exhaust etc.

Coil cooler is type of remote radiator.

• There should be no restriction at the fan outlet (from

where the hot air is going out) such as ceiling.

• If the remote radiator is connected in primary circuit

care should be taken that maximum vertical

distance from engine water pump to highest point

in cooling system should not exceed 5 m.

The max. horizontal distance of remote radiator

from engine should not exceed 10 m.

Mounting

• No special masonry is necessary except to keep

the remote radiator in leveled surface. Normally 150

to 200 mm (6" to 8" ) foundation should be made to

place the remote radiator. It is preferable to elevate

the remote radiator as additional protection from

drainage, for easy installation and to minimise the

chances of dust / dirt getting attracted from ground.

Pillar or mounting structure of approx. 1 m is usual

practice in such case.

• In case of roof top installations, check your building

specifications for permissible floor loading as

mentioned above.

Expansion / Deaerating Tank

A suitable expansion / deration tank must be used along with

remote radiator (Normally 20% of the system capacity). The

tank should be located at the highest point (min. 0.5 m from

radiator top) of entire cooling system. Due to the requirement

of positive pressure at water pump inlet the expansion tank is

usually installed in cold water line. i.e. the outlet of radiator

and near to the engine pump suction line. Ensure proper venting

of total cooling system.

Water Piping and Connections

The most important factor in the piping layout of remote radiator

is the size of the pipe. The exact size of the pipe is essential

so as to get proper flow rate of water and for achieving the

pressure drop within prescribed limits. It is advisable to use

MS pipe of Schedule 20. It is recommended to use flexible

joints in the pipeline close to the DG set.

Piping size should be such that external restriction of piping

and remote radiator is within limit. The maximum pressure

drop allowed in HT and LTA circuit is 0.35 kg/cm

2

(5 psi) and

0.28 kg/cm

2

(4 psi) respectively.

Valves and Fittings

Butterfly valves should be used in the pipe line for isolating

the engine so that the entire system does not have to be drained

during maintenance in the DG set or Remote radiator.

Coolant Treatment

Cooling system capacities with remote radiator are high. It is

mandatory to use additional coolant additive to treat high

volume of water.

Note : Remote radiator can also be used in secondary circuit

in place of cooling towers.

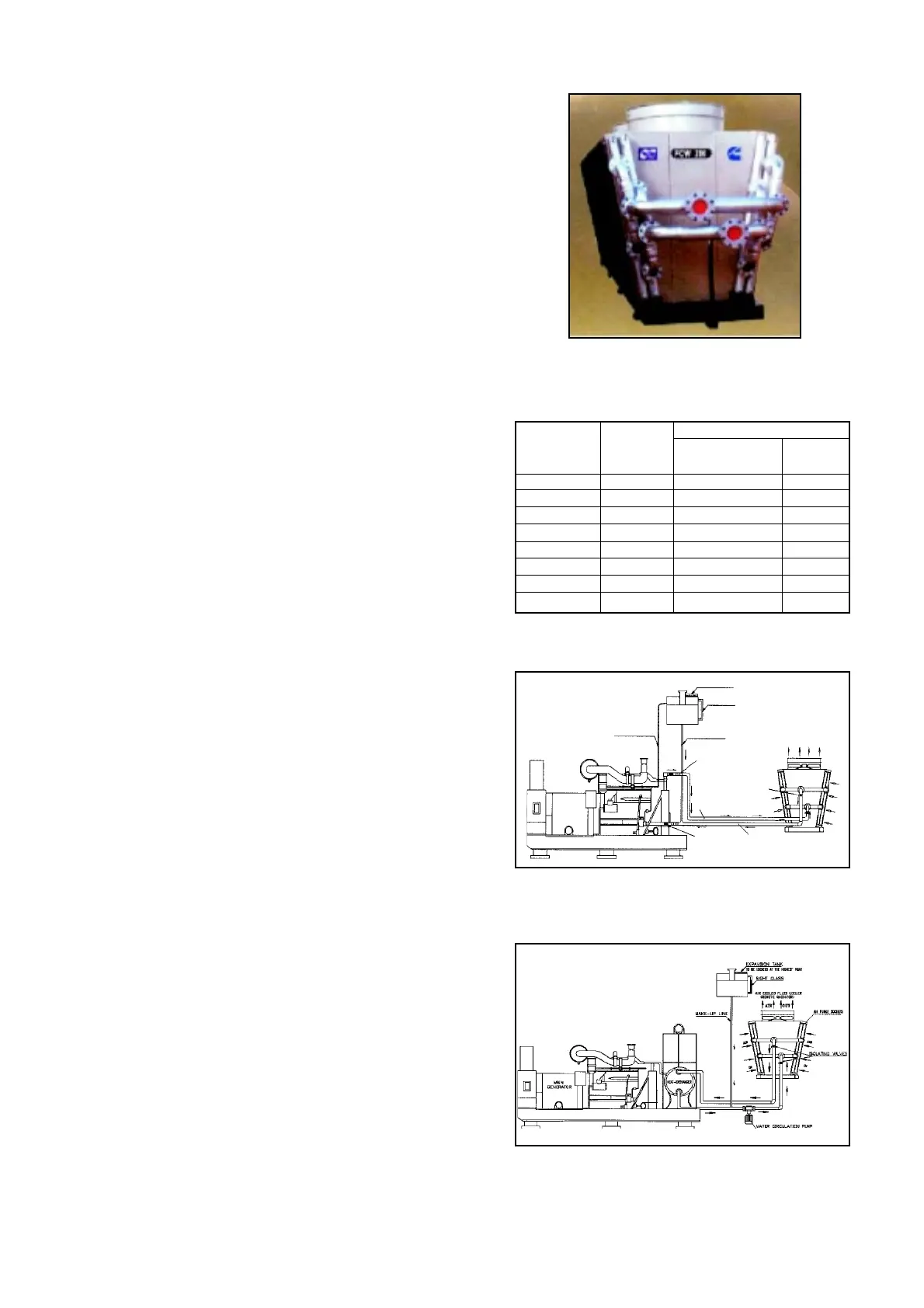

Quick Selection of Remote Radiator for Cummins Engine

Engine Model Prime rating Remote Radiator

KVA Primary Secondary

Circuit Circuit

QSK60G4 2000 FCW-160 (LT + HT) FCW-200

KTA50G8-I 1500 FCW-140 (LT + HT) FCW-180

KTA50G3 1250 FCW-120 FCW-140

KTA50G3 1P2L 1250 FCW-120 (LT + HT) FCW-140

KTA38G5 1000 FCW-100 (LT + HT) FCW-120

KTA2300 750 FCW-080 FCW-100

VTA28G5 600/625 FCW-060 FCW-080

KTA19G4 500 FCW-060 (LT + HT) FCW-080

REMOTE RADIATOR IN SECONDARY CIRCUIT

REMOTE RADIATOR IN PRIMARY CIRCUIT

EXPANSION TANK

TO BE LOCATED AT THE HIGHEST POINT

SIGHT GLASS

MAKE UP LINE

AIR COOLED FLUID COOLER

(REMOTE RADIATOR)

AIR

OUT

GAUGES (TYP)

ISOLATING VALVE

AIR

AIR IN

SUPPLY LINE

FLEXIBLE JOINT

(TYP)

RETURN LINE

1/4” VENT LINE

MAIN

GENERATOR

Loading...

Loading...