14 Piping installation

Installation and operation manual

31

SV1A25AJV1B+SV4~8A14AJV1B

VRV 5 safety valve unit

4P709466-1 – 2023.09

14.1 Installation limitations

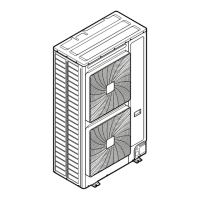

The illustration and table below show the installation limitations.

a, b See table below.

c Maximum limit of 16 downstream ports of SV units in

refrigerant flow-through. Unused ports must also be

counted. E.g. 16ports=SV8A+SV4A+SV4A.

d At least one indoor unit must be connected to a SV unit

(SV6A and SV8A: always start from one of the first four

ports).

e Combine two ports when indoor unit capacity is over 140

except when SV1A is used. Refer to the table below.

f Direct connection to the outdoor unit. See the installation

and operation manual of the outdoor unit.

g SV unit

Description Model

SV1 SV4 SV6 SV8

Maximum number of connectable indoor units

per SVunit (a)

5 20 30 40

Maximum number of connectable indoor units

per SVunit branch (b)

5

Maximum capacity index of connectable

indoor units per SVunit (a)

250 400 600 650

Maximum capacity index of connectable

indoor units per branch (b)

250 140

Maximum capacity index of connectable

indoor units per branch if two branches are

combined (e)

— 250

Maximum capacity index of indoor units

connected to SV units in refrigerant flow-

through (c)

650

Maximum number of allowable SVunits in

refrigerant flow-through (c)

4

Maximum number of ports of SVunits in

refrigerant flow-through (c)

16

Maximum number of indoor units connected to

SVunits in refrigerant flow-through (c)

64

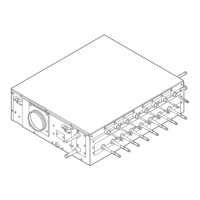

14.1.1 Piping installation limitation

In case of models SV6A and SV8A: at least one of the first four ports

of the SV unit MUST be connected. In case none of the first four

ports are connected, the 7-segment display will show ' '.

Model Branch pipe port

A B C D E F G H

SV6A ≥1port MUST be connected free use

SV8A free use

14.2 Preparing refrigerant piping

14.2.1 Refrigerant piping requirements

NOTICE

The piping and other pressure-containing parts shall be

suitable for refrigerant. Use phosphoric acid deoxidised

seamless copper for refrigerant piping.

▪ Foreign materials inside pipes (including oils for fabrication) must

be ≤30mg/10m.

14.2.2 Refrigerant piping material

▪ Piping material: phosphoric acid deoxidised seamless copper

▪ Piping temper grade and thickness:

Outer diameter

(Ø)

Temper grade Thickness (t)

(a)

6.4mm (1/4")

9.5mm (3/8")

12.7mm (1/2")

Annealed (O) ≥0.80mm

15.9mm (5/8") Annealed (O) ≥0.99mm

19.1mm (3/4")

22.2mm (7/8")

Half hard (1/2H) ≥0.80mm

28.6mm (11/8") Half hard (1/2H) ≥0.99mm

(a)

Depending on the applicable legislation and the maximum

working pressure of the unit (as indicated on the unit nameplate),

larger piping thickness might be required.

14.2.3 Refrigerant piping insulation

▪ Use polyethylene foam as insulation material:

▪ with a heat transfer rate between 0.041 and 0.052W/mK (0.035

and 0.045kcal/mh°C)

▪ with a heat resistance of at least 120°C

▪ Insulation thickness:

Ambient

temperature

Humidity Minimum thickness

≤30°C 75% to 80% RH 15mm

Loading...

Loading...