15 Electrical installation

Installation and operation manual

33

SV1A25AJV1B+SV4~8A14AJV1B

VRV 5 safety valve unit

4P709466-1 – 2023.09

a Insulation tube (field supply)

b Tape (field supply)

c Insulation tube (SV unit)

d Adherence surface

e SV unit

1 Install an insulation tube (a) over the pipe and against the

insulation tube (c) on the SV unit.

2 Apply tape (b) to close the seam.

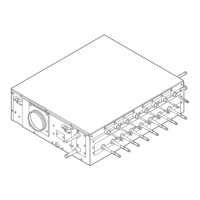

To insulate the header and branch pipes (extra insulation)

Depending on ambient conditions (see "14.2.3 Refrigerant piping

insulation"[431]), it can be required to add extra insulation material.

Make sure that the insulation is properly mounted over the header

and branch pipes of the unit as shown in the image below. In order

to level out the difference in thickness, an extra insulation tube must

be installed over the insulation tube coming out of the unit. Always

use tape (field supply) to prevent air gaps in the seam between the

insulation tubes.

a Insulation tube (extra thick)(field supply)

b Tape (field supply)

c Insulation tube (SV unit)

d Adherence surface

e SV unit

f Insulation tube for levelling out thickness (field supply)

1 Install an insulation tube (a) over the pipe and against the

insulation tube (c) on the SV unit.

2 Attach an extra layer of insulation tube (f) to level out the

thickness.

3 Apply tape (b) to close the seam.

15 Electrical installation

CAUTION

See "2 Specific installer safety instructions" [4 4] to make

sure this installation complies with all safety regulations.

15.1 Specifications of standard wiring

components

NOTICE

We recommend using solid (single-core) wires. If stranded

wires are used, slightly twist the strands to consolidate the

end of the conductor for either direct use in the terminal

clamp or insertion in a round crimp-style terminal. Details

are described in "Guidelines when connecting the electrical

wiring" in the installer reference guide.

Field wiring consists of:

▪ power supply wiring (including earth),

▪ DIII interconnection wiring between units.

NOTICE

▪ Keep the power line and transmission line apart from

each other. Transmission wiring and power supply

wiring may cross, but may NOT run parallel.

▪ In order to avoid any electrical interference, the

distance between both wirings should ALWAYS be at

least 50mm.

Component Units

SV1A SV4A SV6A SV8A

Power supply

cable

MCA

(a)

0.1A 0.2A 0.3A 0.3A

Voltage 220-240V

Phase 1~

Frequency 50Hz

Wire size Must comply with national wiring

regulation.

3-core cable

Wire size based on the rated

current, but not less than 0.5mm².

Interconnection

wiring

Voltage 220-240V

Wire size Only use harmonised wire

providing double insulation and

suitable for the applicable voltage.

2-core cable

0.75mm²-1.5mm²

Recommended field fuse 6A

Residual current device Must comply with national wiring

regulation.

(a)

MCA=Minimum circuit ampacity. Stated values are maximum

values.

Power supply wiring

The power supply wiring must be protected with the required safety

devices, i.e. a main switch, a slow blow fuse on each phase and an

earth leakage protector in accordance with the applicable legislation.

Selection and sizing of the wiring should be done in accordance with

the applicable legislation based on the information mentioned in the

table above.

Interconnection wiring

The interconnection wiring outside the unit should be wrapped and

routed together with the field piping. See "15.4To finish the electrical

wiring"[436] for more information.

Selection and sizing of the wiring should be done in accordance with

the applicable legislation based on the information mentioned in the

table above.

Interconnection wiring specification and limits

(a)

Maximum wiring length between SV unit and indoor

units

1000m

Maximum wiring length between SV unit and

outdoor unit

1000m

Maximum wiring length between SV units 1000m

Total wiring length 2000m

(a)

If the total interconnection wiring exceeds these limits,

communication errors might occur.

Up to 16 branches are possible for unit-unit cabling. No secondary

branching are allowed after any interconnection wire branching.

Loading...

Loading...