Test Operation SiUS331604E

73 Field Setting

1. Test Operation

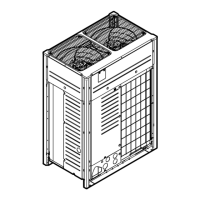

Follow the following procedure to conduct the initial test operation after installation.

1.1 Check Work Prior to Turning Power Supply ON

1.2 Turn Power ON

Check on refrigerant piping /

insulation material

Check on amount of refrigerant

charge

Check the below items.

• Power wiring

• Control transmission wiring

between units

• Earth wire

•

Is the power supply appropriate?

• Have you finished a ductwork to drain?

• Have you detach transport fitting?

• Is the wiring performed as specified?

• Are the designated wires used?

• Is the grounding work completed?

Use a 500 V Megger tester to measure the insulation.

Do not use a Megger tester for low voltage circuits.

• Are the setscrews of wiring not loose?

• Is the electrical component box covered with an insulation cover

completely?

• Is refrigerant charged up to the specified amount?

If insufficient, charge the refrigerant from the service port of stop

valve on the liquid side with outdoor unit in stop mode after turning

power ON.

• Has the amount of refrigerant charge been recorded on “Record

Chart of Additional Refrigerant Charge Amount”?

• Is pipe size proper? (The design pressure of this product is 4.0

MPa (580 psi).)

• Are pipe insulation materials installed securely?

Liquid and gas pipes need to be insulated. (Otherwise causes

water leak.)

• Are respective stop valves on liquid and gas line securely open?

Turn outdoor unit power ON.

Turn indoor unit power ON.

• Be sure to turn the power ON 6 hours before starting operation to

protect compressors.

• Close outside panels of the outdoor unit.

Carry out field setting on

outdoor PCB

Loading...

Loading...