Dakewe(Shenzhen)Medical Equipment Co,. Ltd 35 V4.1

5.8 Specimen Cryoforming

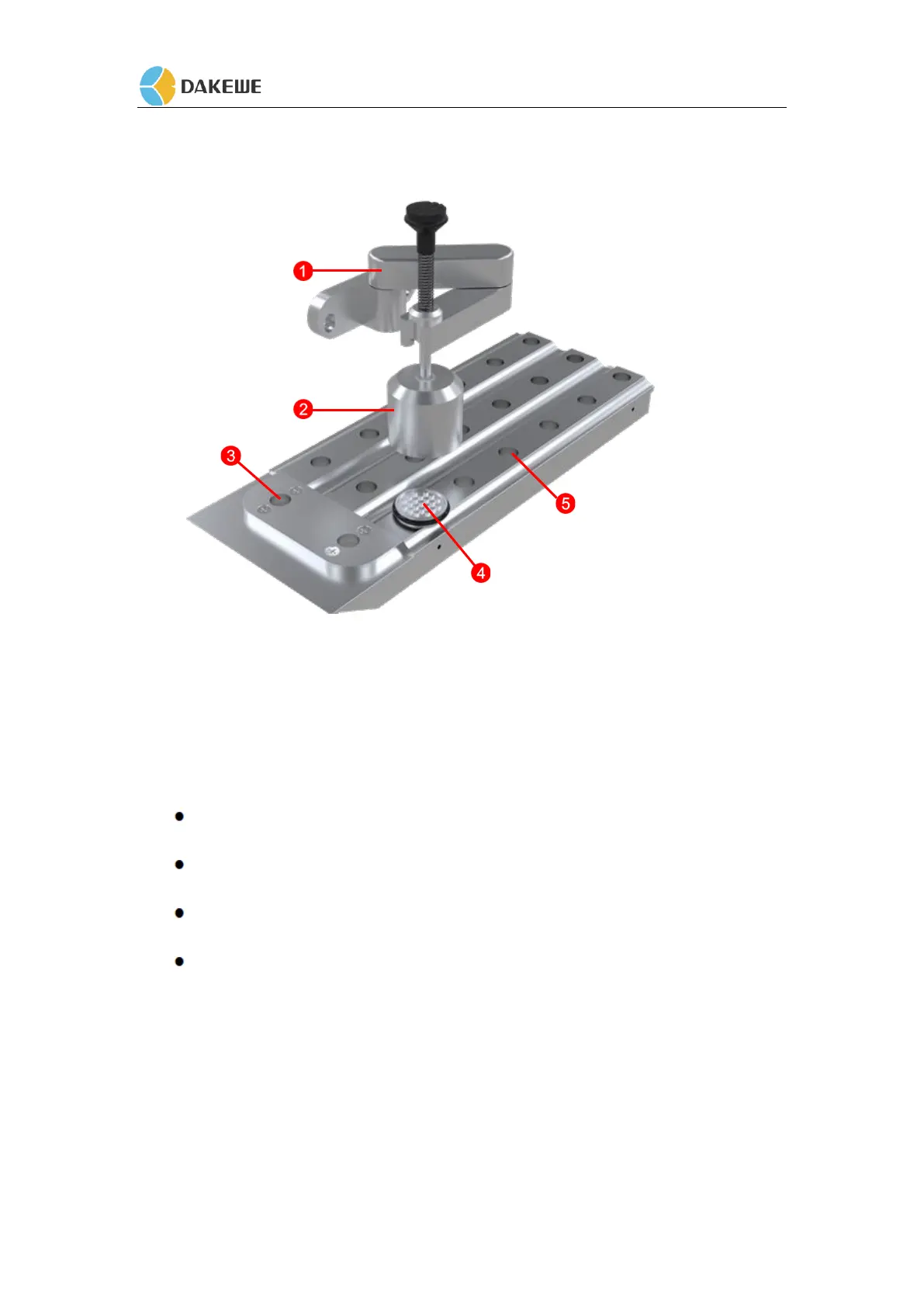

1. Hammer bracket 2. Hammer 3. Semiconductor fast cooling hole

4. Sample disk 5. Ordinary cooling hole

The specimen freezer is fixed on the left side of the freezer compartment, and there are 20 holes

in which the carrier head is placed, two of which are semiconductor rapid cooling holes and 18

are ordinary cooling holes. The temperature of the freezer is always lower than the temperature

in the freezer.

At normal temperature, cut the specimen into the appropriate size and place it on the carrier

head and position it with the embedding agent.

Insert the Sample disk with sample into the hole of the freezer and freeze it at low

temperature.

During specimen freezing, a heavy hammer can be placed on the specimen surface to

accelerate the freezing of the specimen surface and flatten the specimen surface;

After the specimen is frozen, insert the carrier into the core of the chuck. Once it is tightened,

start slicing.

Loading...

Loading...