VII. Abnormalities and Troubleshooting

Dakewe (Shenzhen) Medical Equipment Co., Ltd. 69

www.dakewemedical.com

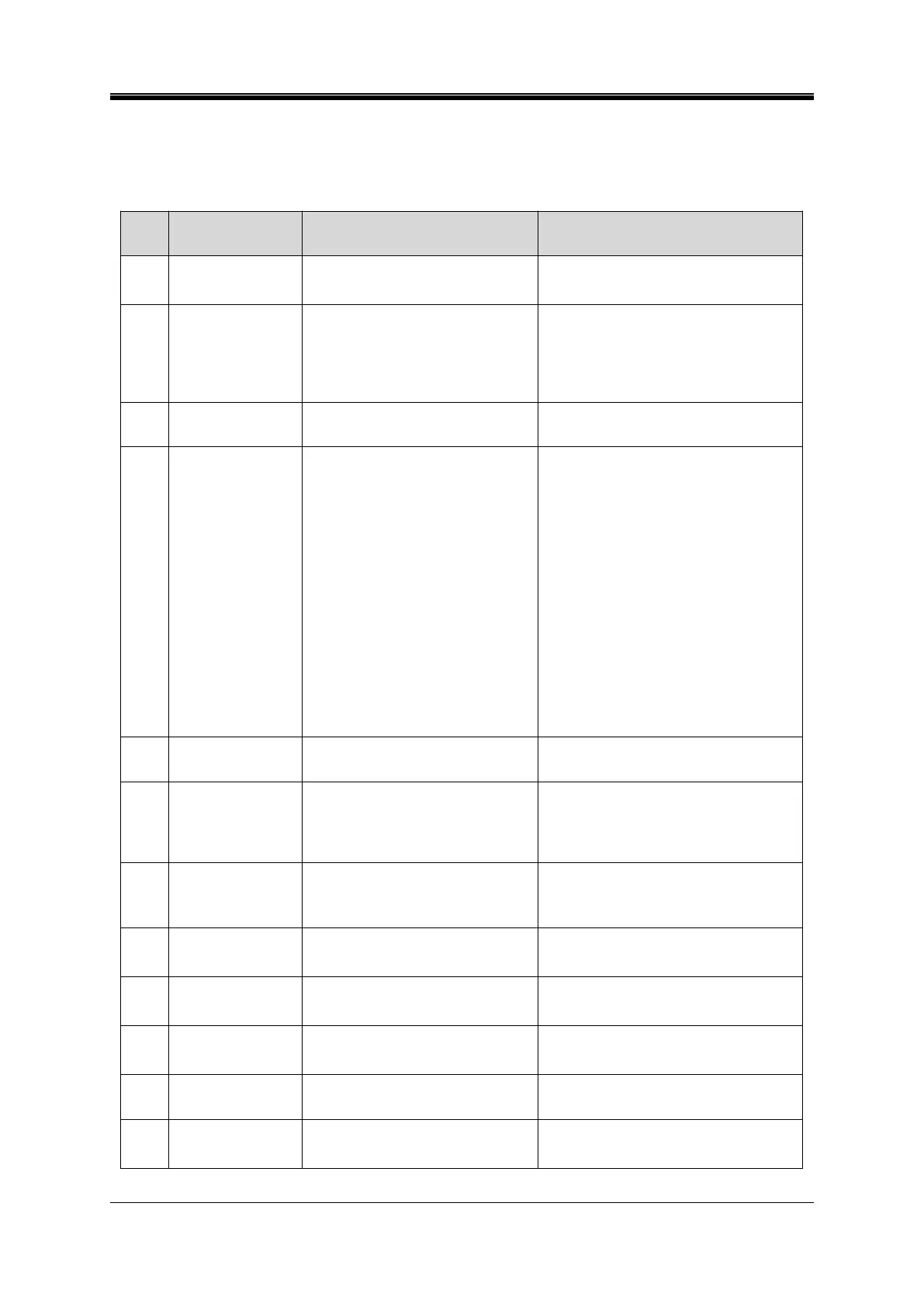

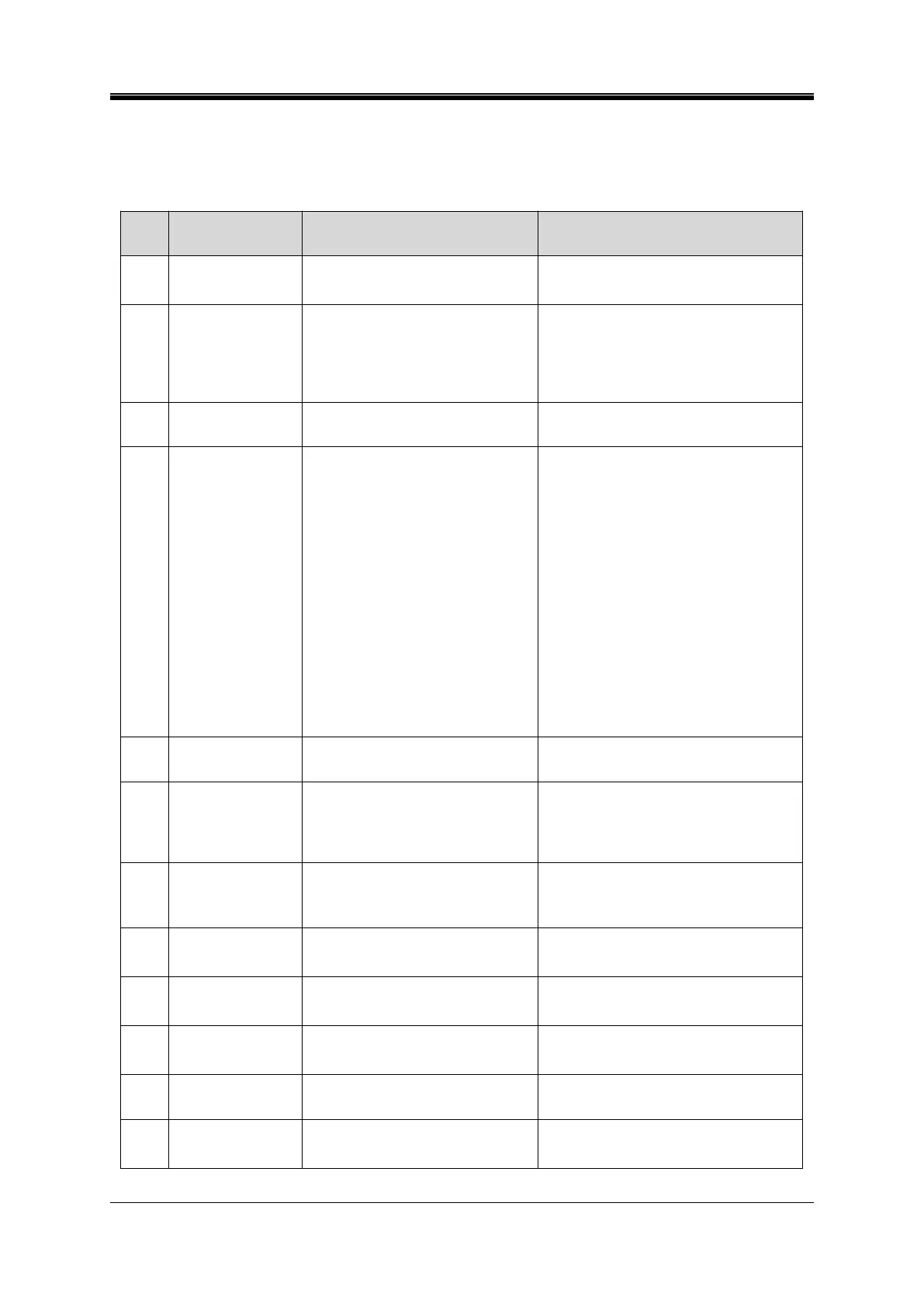

(3) List of Common Abnormalities

Table 7- 2 List of common abnormalities

Slides occasionally

fail to slide down

smoothly

Shake the slide

Dry the slide prior to printing

Change the type of slide used

No prompt displays

when the slide does

not slide down

smoothly

The detection function of the

on-demand output is not turned on

The non-slide parameter threshold for

the on-demand output is set

unreasonably; The sensor of the

on-demand output is abnormal

Enable the detection function of the

on-demand output; Reset the no-slide

parameter threshold for the on-demand

output; Troubleshoot the sensor of the

on-demand output

The slide is stuck in the output hopper

Take out the stuck slide from the output

hopper

The input hopper is not properly

inserted

Too many slides in the input hopper

The height difference of the two sides

the piles of the slides is greater than

1.5 mm

Slide sticking

Broken edge of slide

Irregularly shaped slide

Damaged paint surface of slide

The slide is placed upside down

Bevelled slides are used

Debris between slides

Debris on the print platform

Debris on the input hopper holder

Check whether the input hopper is properly

inserted; Reduce slides in the input hopper

to below the mark; Reduce slides until

printing properly; Check whether the slides

in the input hoppers are adhere to each

other; Check whether the edge of slides is

broken; Check whether the slides are

regular; Check whether the paint surface of

slide is damaged; Check whether the slides

in the input hopper are placed upside down

Change the type of slide used

Check whether there is glass debris between

the slides in the input hoppers

Check whether there is glass debris on the

print platform; Check whether there is glass

debris on the input hopper holder

Disable the on-demand mode and auto

mode

Stop immediately

during print

Open the maintenance door

Training and presentation

The preset options

in the drop-down

box in the main

interface are

abnormal

The separator entered is the Chinese

comma

Enter the English comma in the preset

option box for presetting

Click the button when the drop-down

box appears

It takes time to load and display the

button-associated content

Click in the blank space, and click the

button after the drop-down box disappears

Wait for complete content loading

Instrument software

disconnection

It takes too long to load the template

Open the PC software and restart the

instrument; Wait for complete template

loading; Delete or adjust the template

Instrument does not

work when online

The network cable is loose or the IP

address is changed

The network interface card is damaged

Restart slide printer

Check the instrument IP

Replace the network interface card

Foreign matters such as smoke or dust

adhere to the laser lens

Filter expired

Clean the laser lens

Replace the filter

Training and presentation

Fail to startup the

instrument

Turn on the instrument within a short

time after turning off the main power

supply

Turn on the instrument 1 min after turning

off the main power supply

Loading...

Loading...