4 Electrical Installation

4.1 How to Connect

4.1.1 Cables General

NOTE

For the VLT HVAC Drive High Power series mains and

motor connections, please see VLT HVAC Drive High

Power Operating Instructions MG.11.FX.YY.

NOTE

Cables General

All cabling must comply with national and local regula-

tions on cable cross-sections and ambient temperature.

Copper (60/75 °C) conductors are recommended.

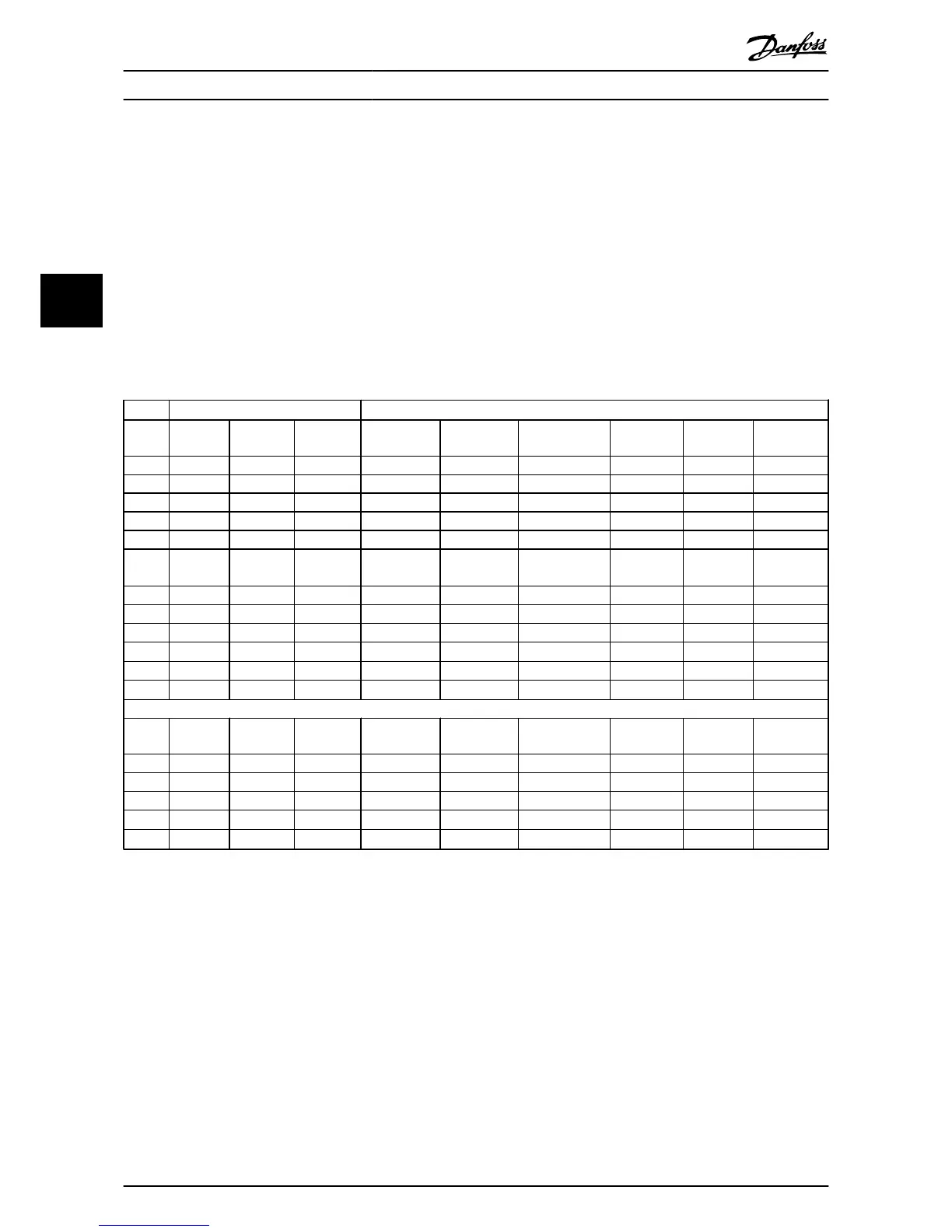

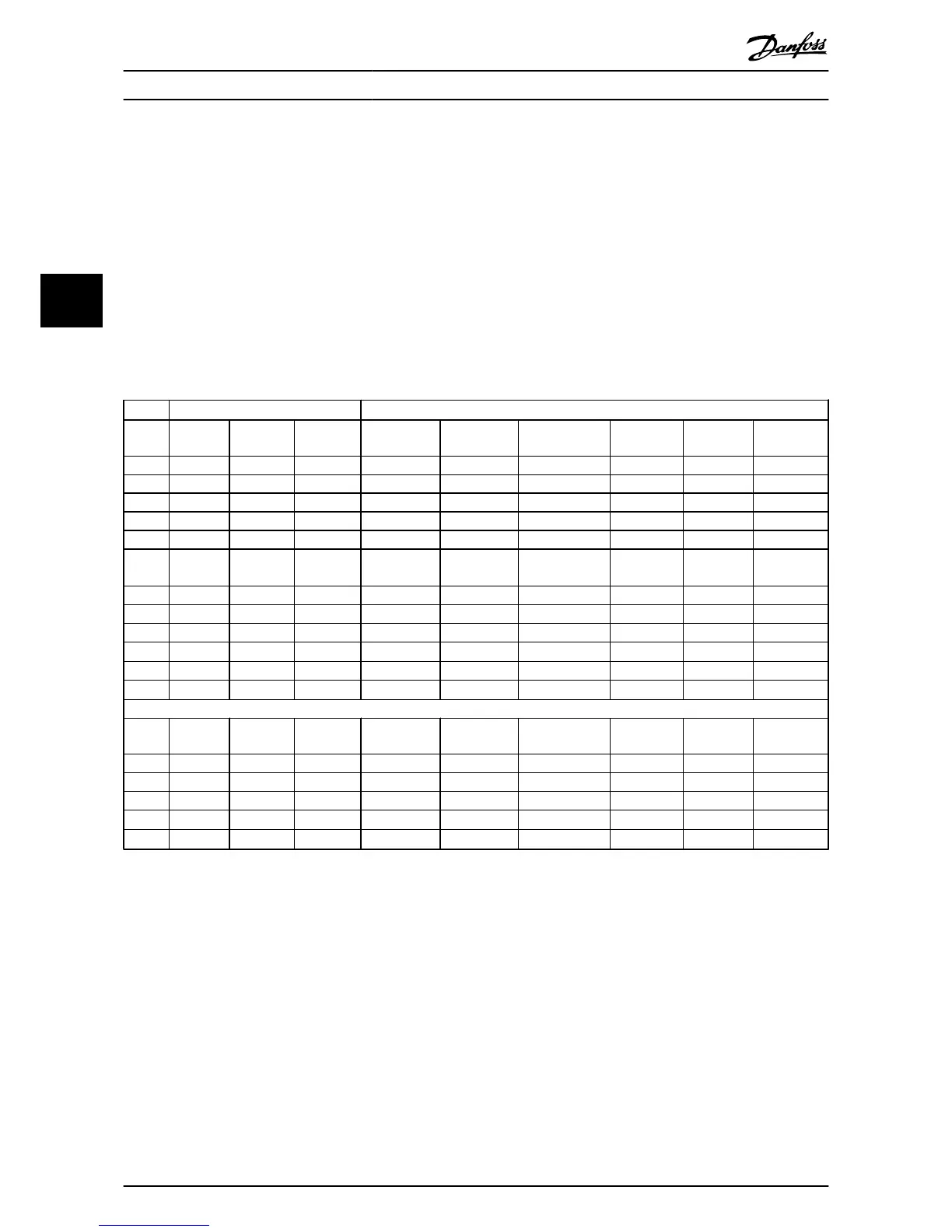

Details of terminal tightening torques.

Power (kW) Torque (Nm)

Enclo-

sure

200-240V 380-480V

525-600

V

Mains Motor

DC

connection

Brake Earth Relay

A2 1.1 - 3.0 1.1 - 4.0 1.1 - 4.0 1.8 1.8 1.8 1.8 3 0.6

A3 3.7 5.5 - 7.5 5.5 - 7.5 1.8 1.8 1.8 1.8 3 0.6

A4 1.1-2.2 1.1-4 1.8 1.8 1.8 1.8 3 0.6

A5 1.1 - 3.7 1.1 - 7.5 1.1 - 7.5 1.8 1.8 1.8 1.8 3 0.6

B1 5.5 - 11 11 - 18.5 11 - 18.5 1.8 1.8 1.5 1.5 3 0.6

B2

-

15

22

30

22

30

4.5

4.5

2)

4.5

4.5

2)

3.7

3.7

3.7

3.7

3

3

0.6

0.6

B3 5.5 - 11 11 - 18.5 11 - 18.5 1.8 1.8 1.8 1.8 3 0.6

B4 15 - 18.5 22 - 37 22 - 37 4.5 4.5 4.5 4.5 3 0.6

C1 18.5 - 30 37 - 55 37 - 55 10 10 10 10 3 0.6

C2 37 - 45 75 - 90 75 - 90

14/24

1)

14/24

1)

14 14 3 0.6

C3 22 - 30 45 - 55 45 - 55 10 10 10 10 3 0.6

C4 37 - 45 75 - 90 75 - 90

14/24

1)

14/24

1)

14 14 3 0.6

High Power

Enclo-

sure

380-480 V Mains Motor DC connection Brake Earth Relay

D1/D3 110-132 19 19 9.6 9.6 19 0.6

D2/D4 160-250 19 19 9.6 9.6 19 0.6

E1/E2 315-450 19 19 19 9.6 19 0.6

F1-F3

3)

500-710 710-900 19 19 19 9.6 19 0.6

F2-F4

3)

800-1000 1000-1400 19 19 19 9.6 19 0.6

Table 4.1: Tightening of terminals

1) For different cable dimensions x/y, where x ≤ 95 mm

2

and y

≥ 95 mm

2

.

2) Cable dimensions above 18.5 kW ≥ 35 mm

2

and below 22

kW ≤ 10 mm

2

.

3) For data on the F frame sizes consult FC 100 High Power

Operating Instructions.

Electrical Installation

VLT

®

HVAC Drive Operating Instructions

20 MG.11.AD.02 - VLT

®

is a registered Danfoss trademark

4

Loading...

Loading...